Electro-hydraulic compound brake system for recovering braking energy of electric fork-lift

A technology of braking energy recovery and electro-hydraulic compounding, applied in electric braking systems, braking safety systems, electric vehicles, etc., can solve problems such as uncomfortable braking, wear of friction pairs, and reduced brake life, and achieve improved The effect of improving energy utilization, ensuring braking safety, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

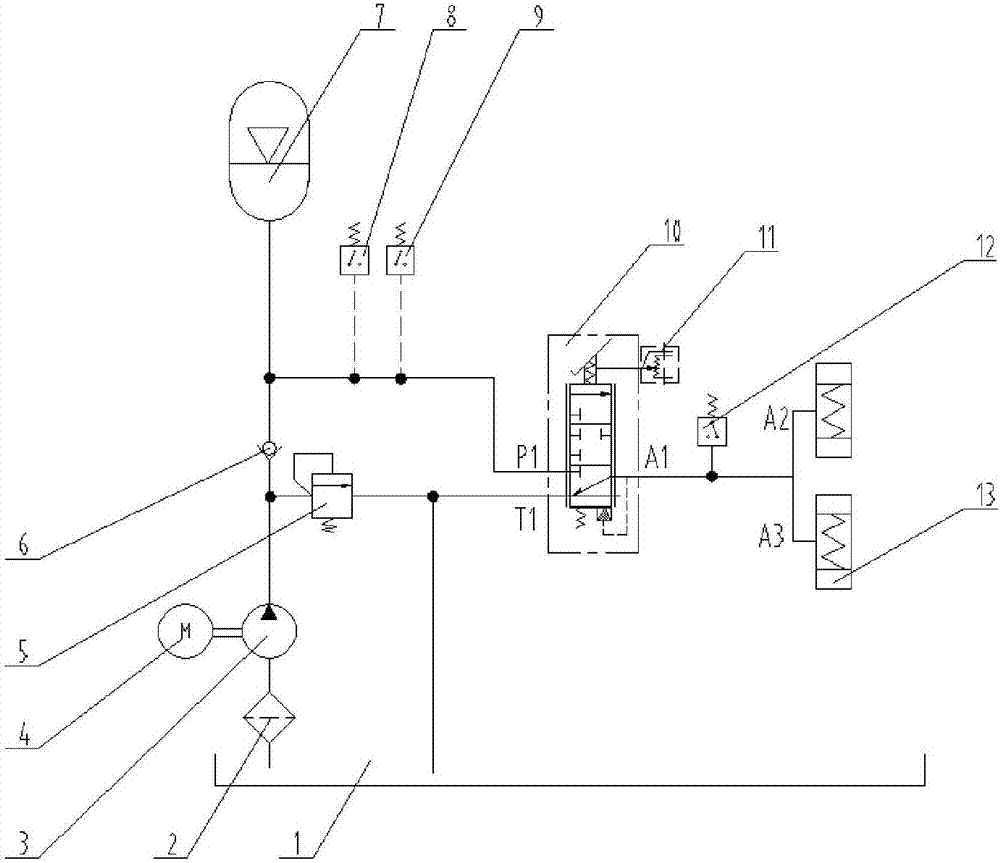

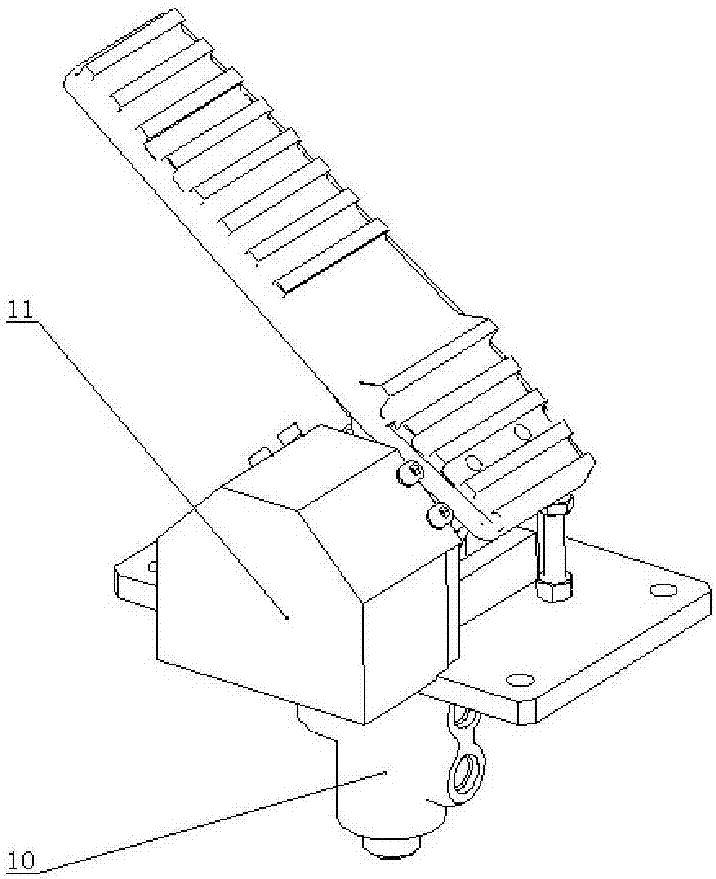

[0015] Such as figure 1 As shown, the electro-hydraulic composite braking system for electric forklift braking energy recovery in this embodiment includes oil suction filter 2, overflow valve 5, check valve 6, accumulator 7, three-position three-way full hydraulic pressure The power brake valve 10, the service brake device, the gear pump 3 controlled by the motor 4, the control device for controlling the rotation or stop of the motor 4, the pedal angle sensor 11 connected with the pedal of the forklift, and the intake filter 2 The oil port extends into the oil in the hydraulic oil tank 1, the oil outlet of the oil suction filter 2 communicates with the oil inlet of the gear pump 3, and the oil outlet of the gear pump 3 is respectively connected to the overflow valve 5 and the single valve through a three-way pipe. It is connected to the oil inlet of valve 6, and the oil ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com