Double-motor driving type electronic hydraulic brake system capable of actively simulating pedal feeling

A dual-motor drive and hydraulic brake technology, applied in brakes, brake transmissions, transportation and packaging, etc., can solve problems such as consumption, reliability and safety hazards, energy waste, etc., to reduce the risk of system failure, The effect of improving the life of the motor and reducing the power of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

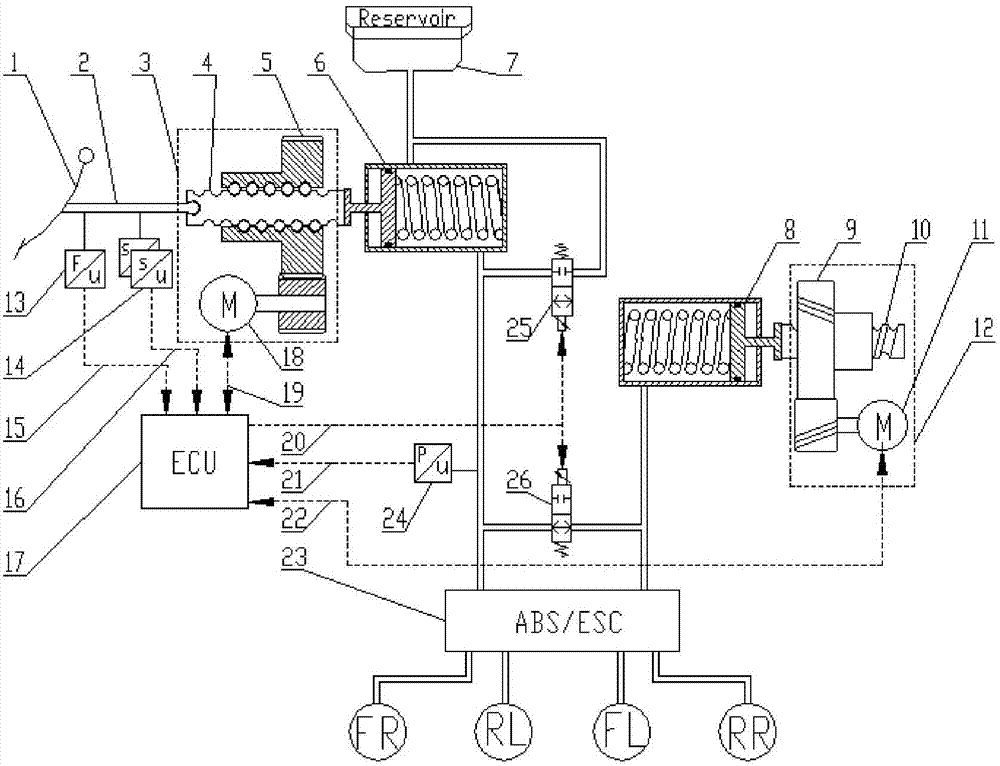

[0041] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0042] Such as figure 1 As shown, a dual-motor-driven electro-hydraulic braking system that can actively simulate the pedal feel, including:

[0043] Brake pedal 1, which receives the driver's braking intention and inputs it into the system;

[0044] One end of the push rod 2 is connected to the brake pedal 1, and the other end is a spherical structure, which is hinged with the ball screw 4 through structural design.

[0045] The brake master cylinder 6 is used to receive the pedal force and the resultant force generated by the corresponding brake motor through the reduction mechanism to establish the required hydraulic braking force;

[0046] The fluid storage tank 7 is used to store brake fluid;

[0047] The secondary master cylinder 8 is used to receive the thrust generated by the corresponding brake motor through the reduction mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com