Inverter electric welding machine device with adjustable electric arc

An inverter welding machine and adjustable technology, applied in arc welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the seam of the welded workpiece cannot be very uniform, the structure of the plasma welding machine is complex, and the plasma arc is not suitable, etc. problems, to achieve the effect of enhancing stability and practicability, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

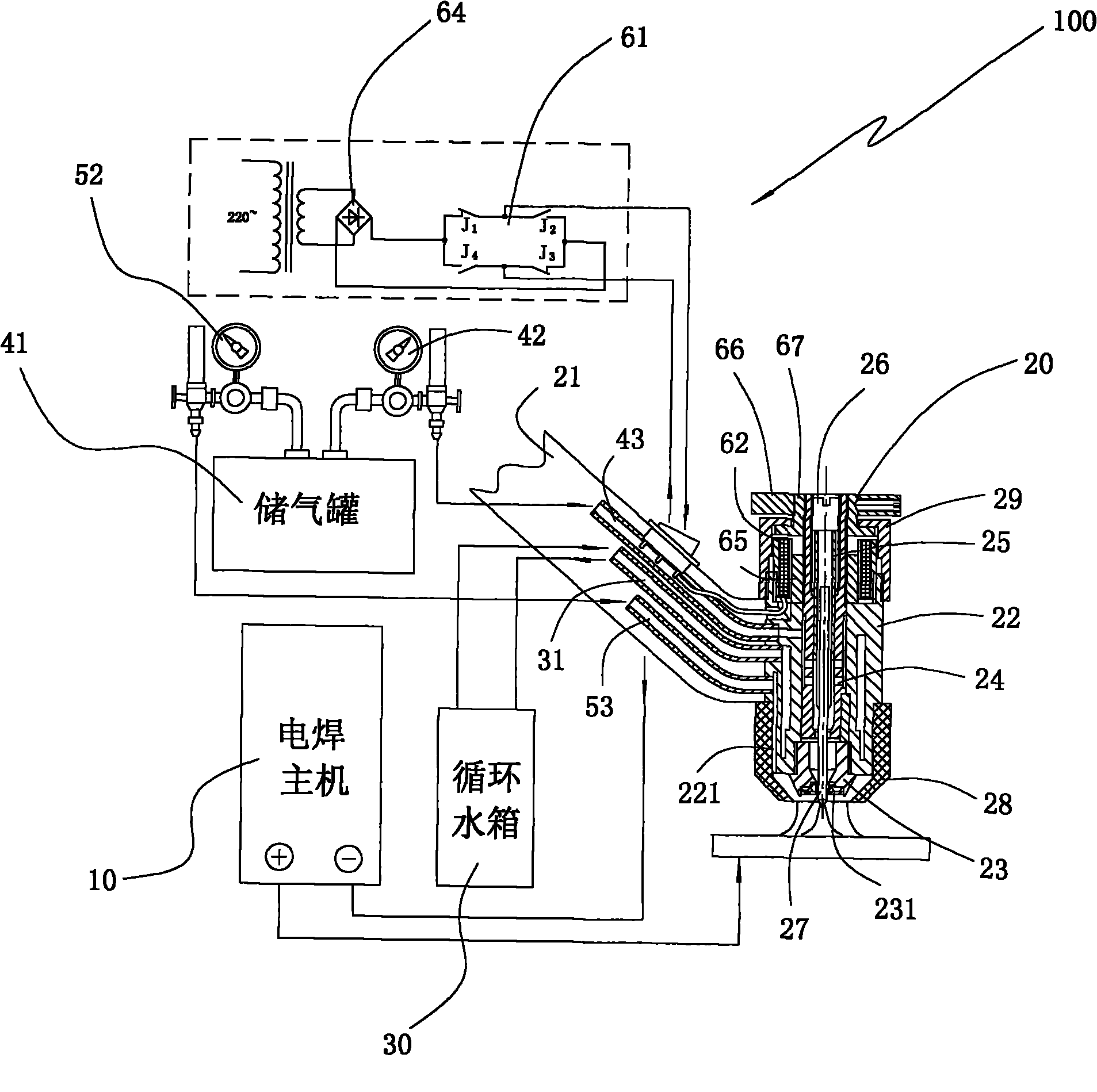

[0015] figure 1 As shown, it is a schematic diagram of the working principle of the adjustable arc inverter welding machine equipment 100 according to the present invention. The inverter welding machine equipment 100 shown in the figure is mainly composed of a main box 10, a welding torch 20, a liquid cooling system, a compressed gas supply system, a shielding gas supply system, and an arc regulating device.

[0016] Wherein, the main machine box 10 is an electric welding machine which is basically the same as an ordinary argon tungsten arc welding machine, and the no-load voltage of the argon arc welding machine adopted is higher than that of an ordinary argon arc welding machine, about 100 volts.

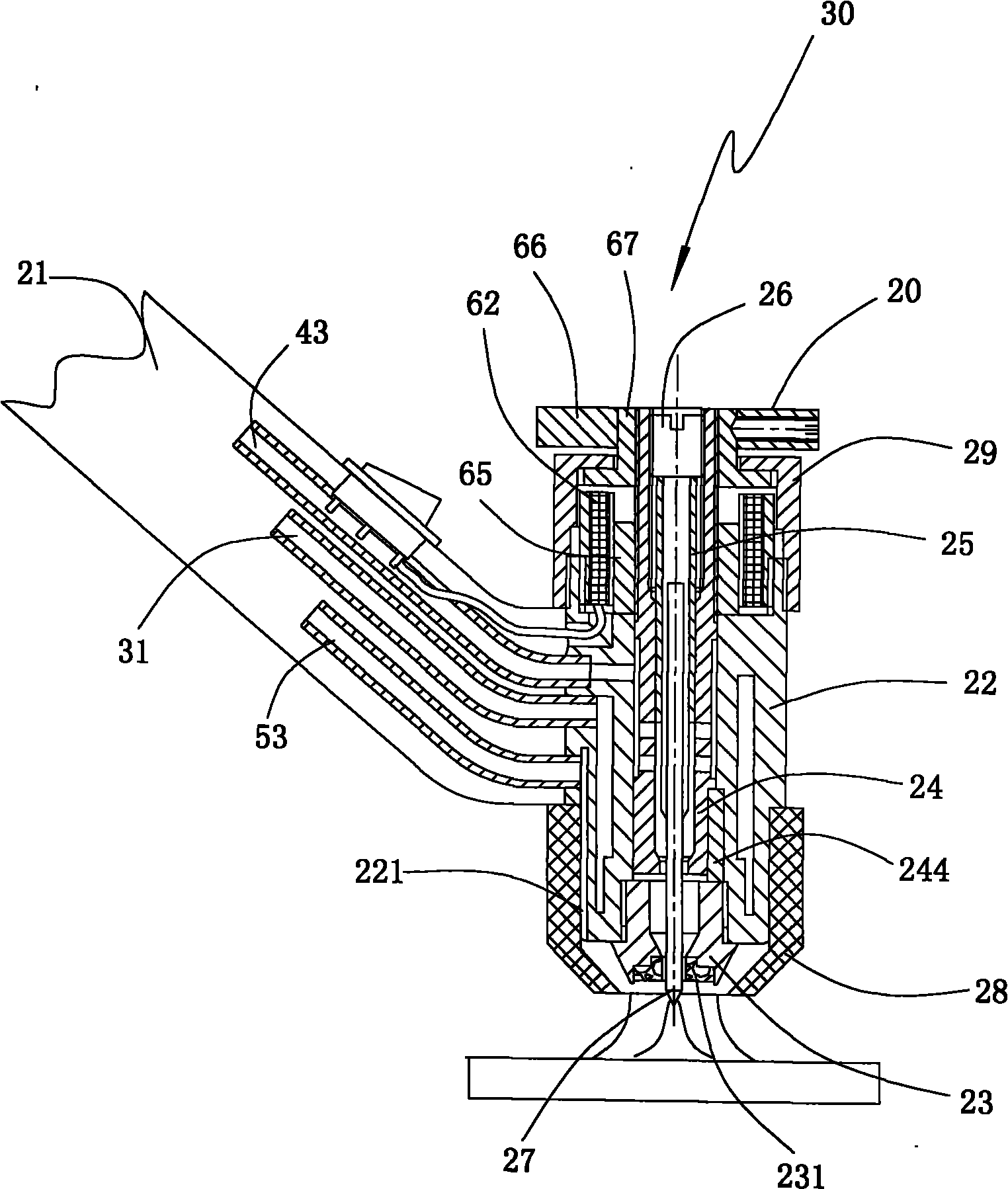

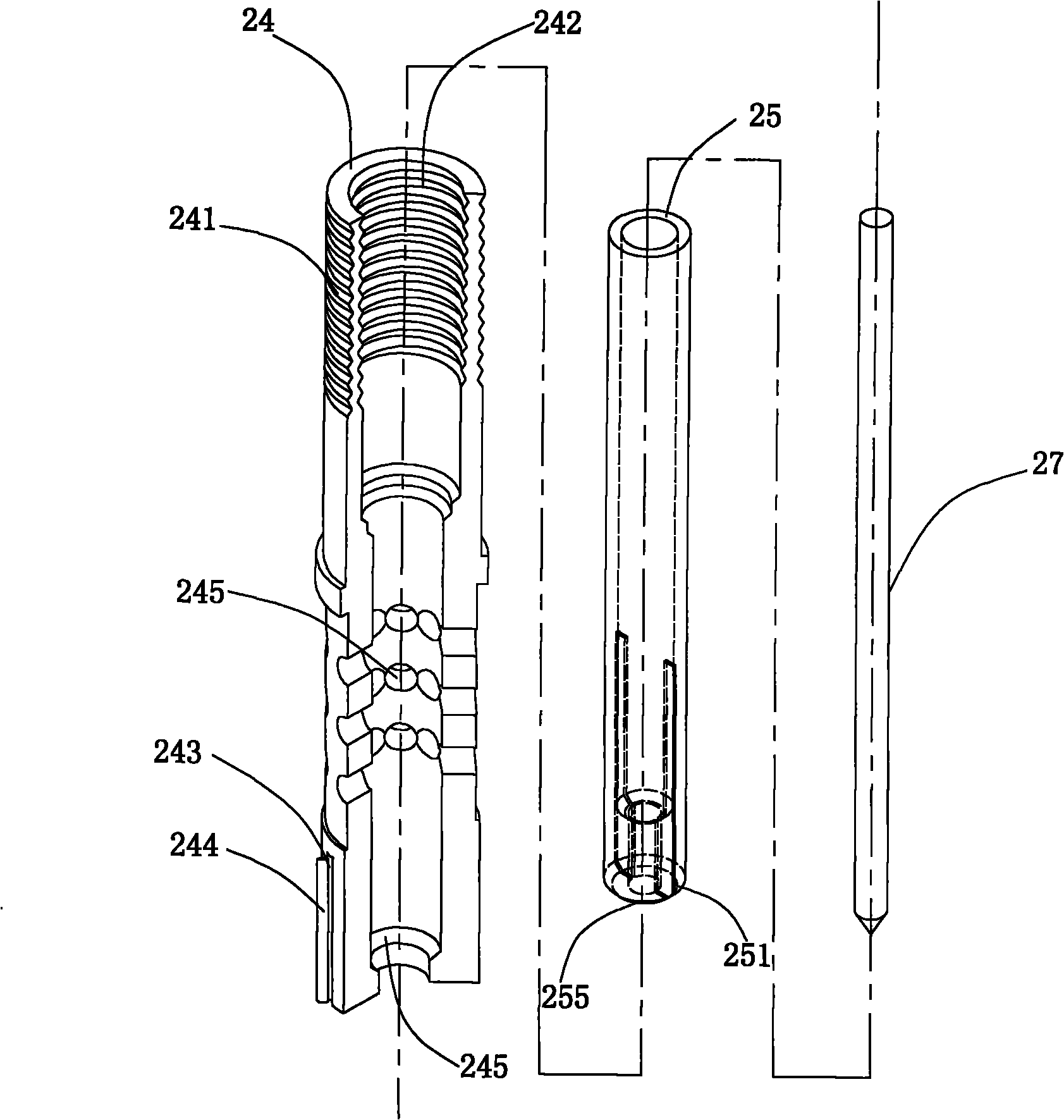

[0017] now refer to figure 2 and image 3 As shown, the welding torch 20 mainly includes a handle 21, a main cylinder 22, a nozzle 23, an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com