Device and method for simulating a welding process

A welding process and equipment technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., to achieve the effects of increased user friendliness, high-precision position determination, and high-accuracy position determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

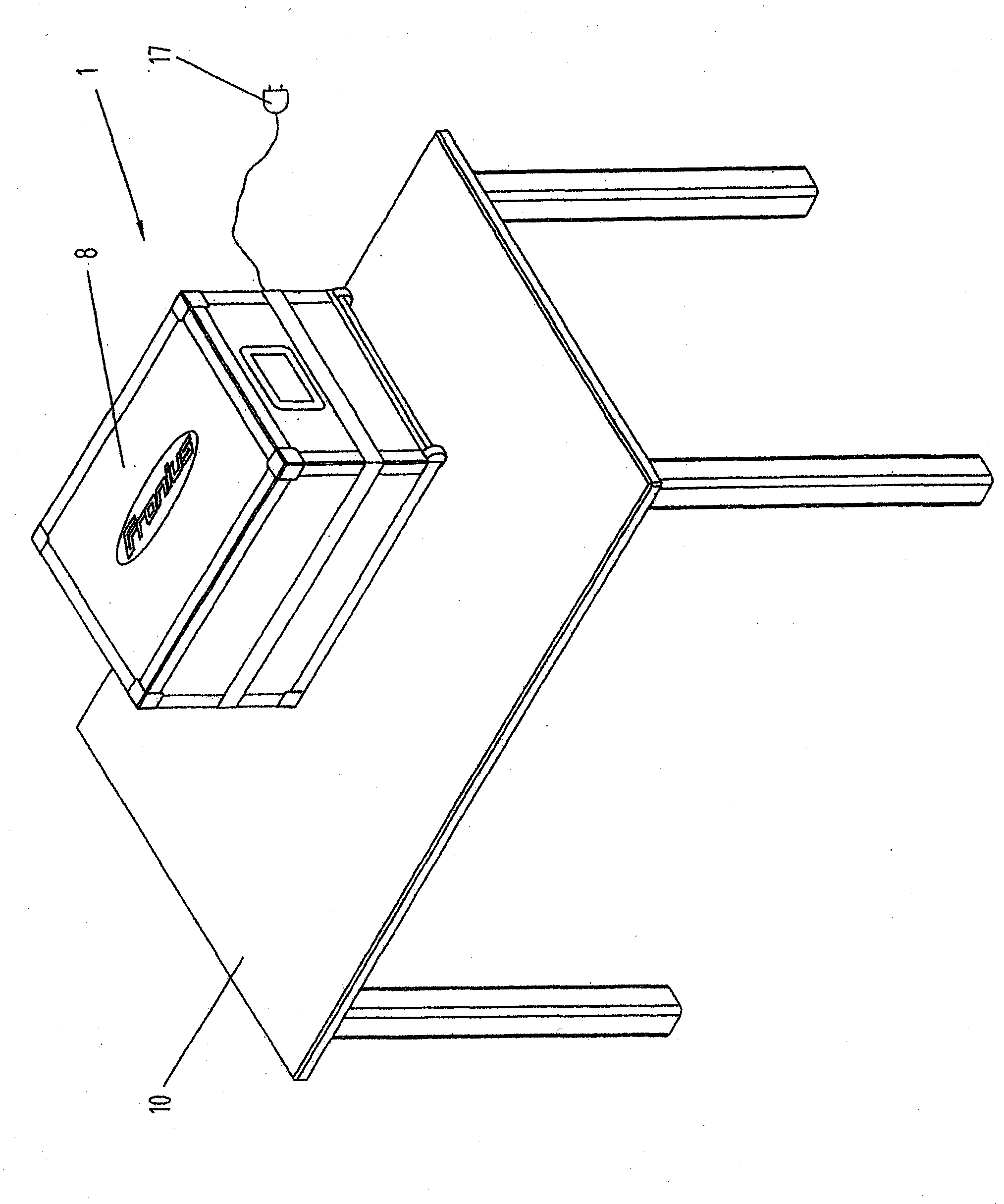

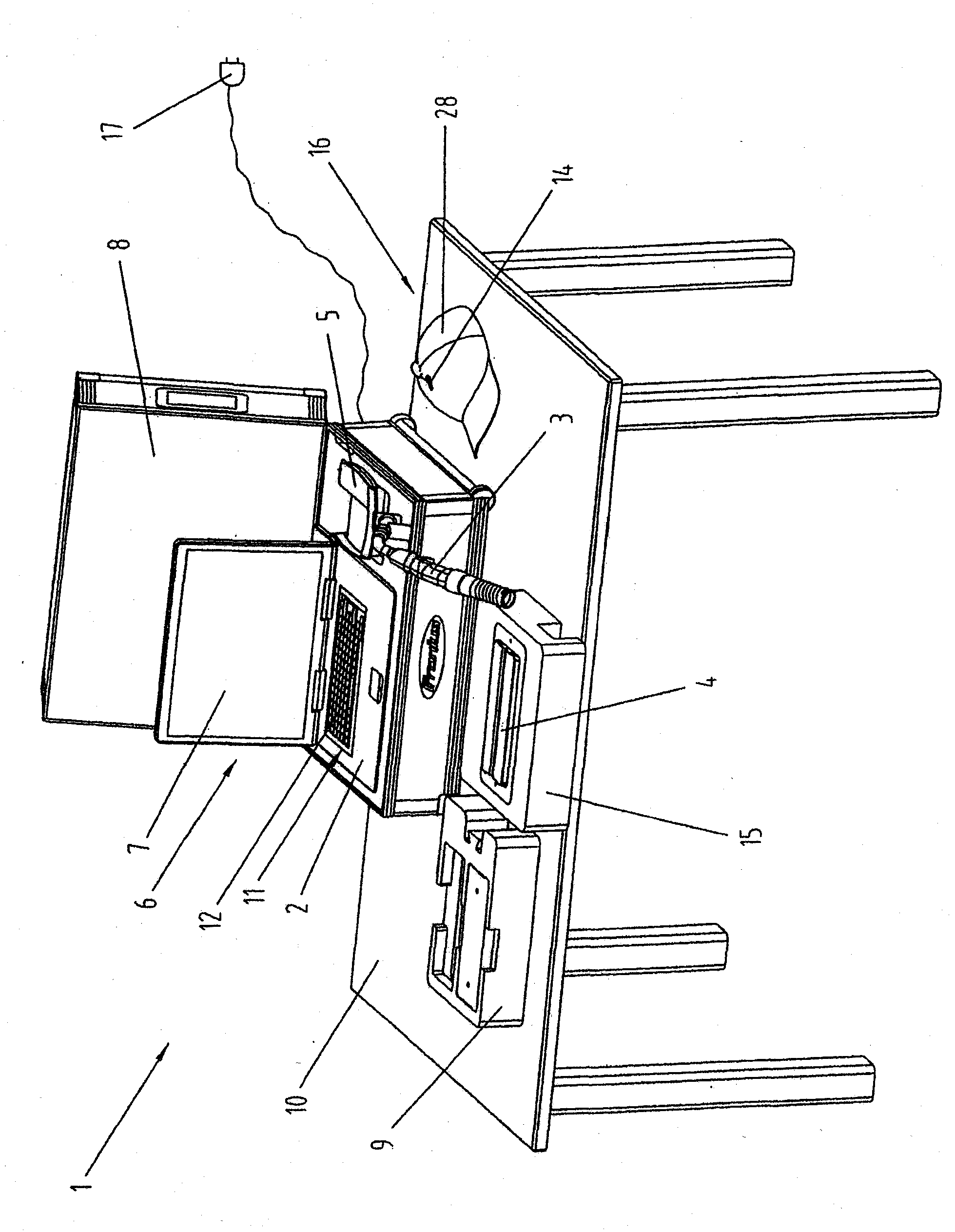

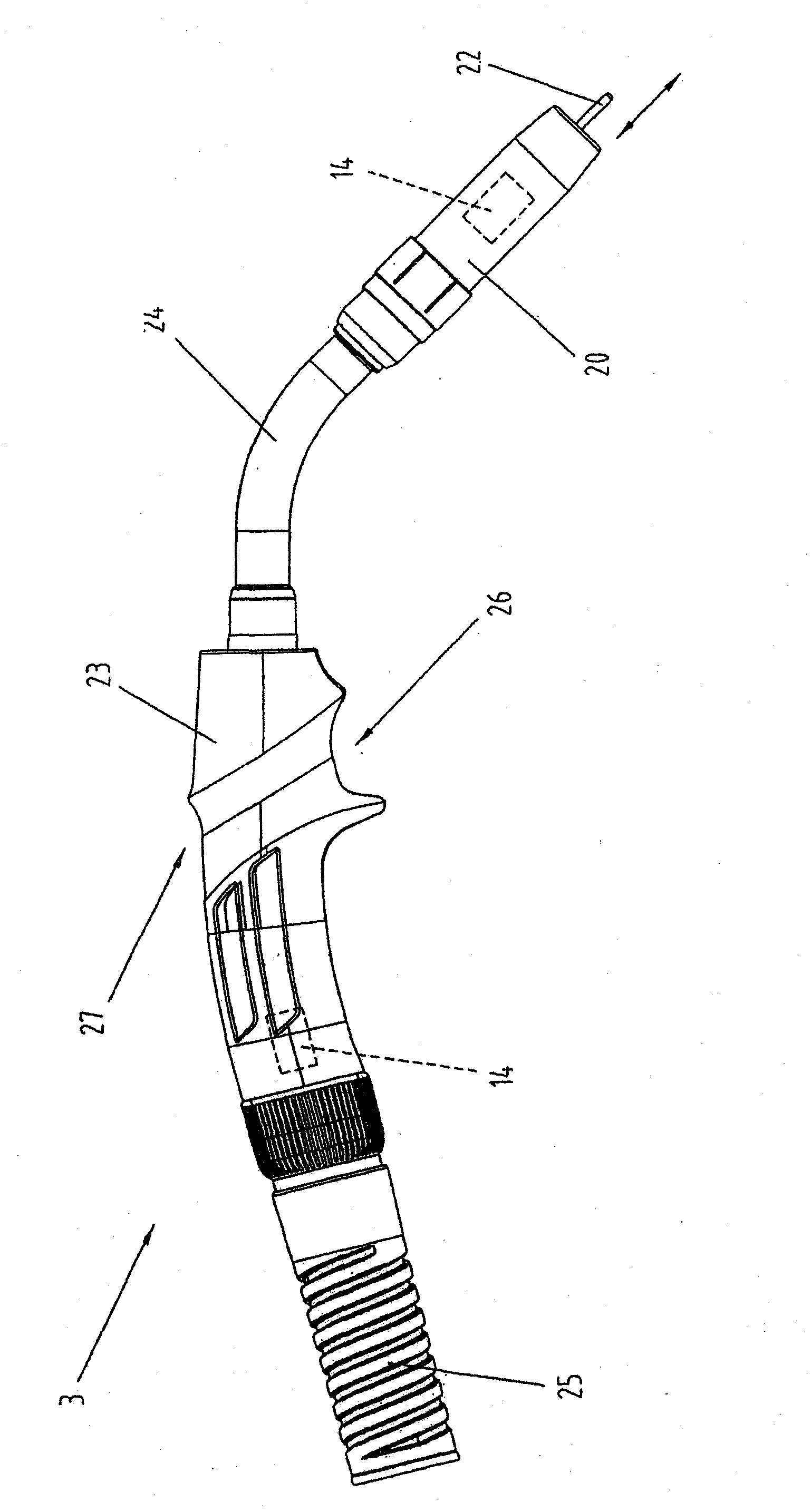

[0047] exist Figure 1 to Figure 12 A device 1 for simulating a welding process is shown in . Basically, it should be noted that in such a device 1 no real welding process takes place, but the welding process is simulated and displayed virtually with the help of software running in the computer 2 . The user is able to practice the welding process with the help of a welding torch 3 available on the market, which is reconfigured for the above-mentioned purpose, ie it enables guiding of the welding torch 3 relative to the workpiece 4 . Such a simulation or practice system offers the advantage that the user can practice the welding process whenever desired without consuming corresponding additional material for the welding process and without workpieces or objects which are subsequently discarded as scrap. Thus, for example, welders can each be trained in a new welding process, or new users can be easily and easily taught a new welding process in a simple manner, before the user ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com