Mono-dispersed nano/micron polymer hollow microsphere resin and method for synthesizing the same

A technology of hollow microspheres and polymers, applied in the field of preparation of nano/micro polymer hollow microspheres, which can solve the problems of difficult removal of stabilizers and dispersants, difficulties in large-scale application of self-assembly methods, and atom transfer radical polymerization conditions Harsh and other problems, to achieve the effect of particle cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

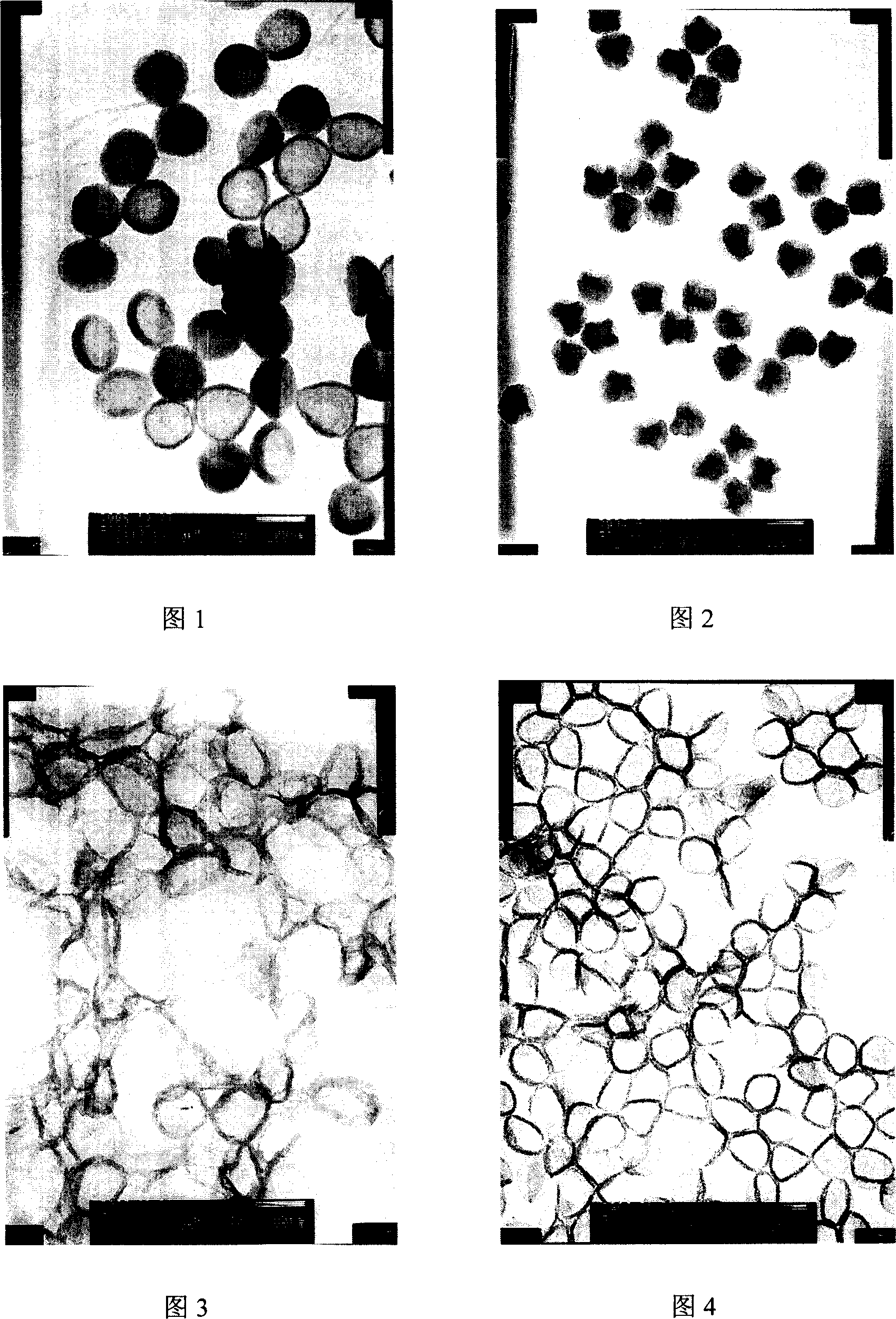

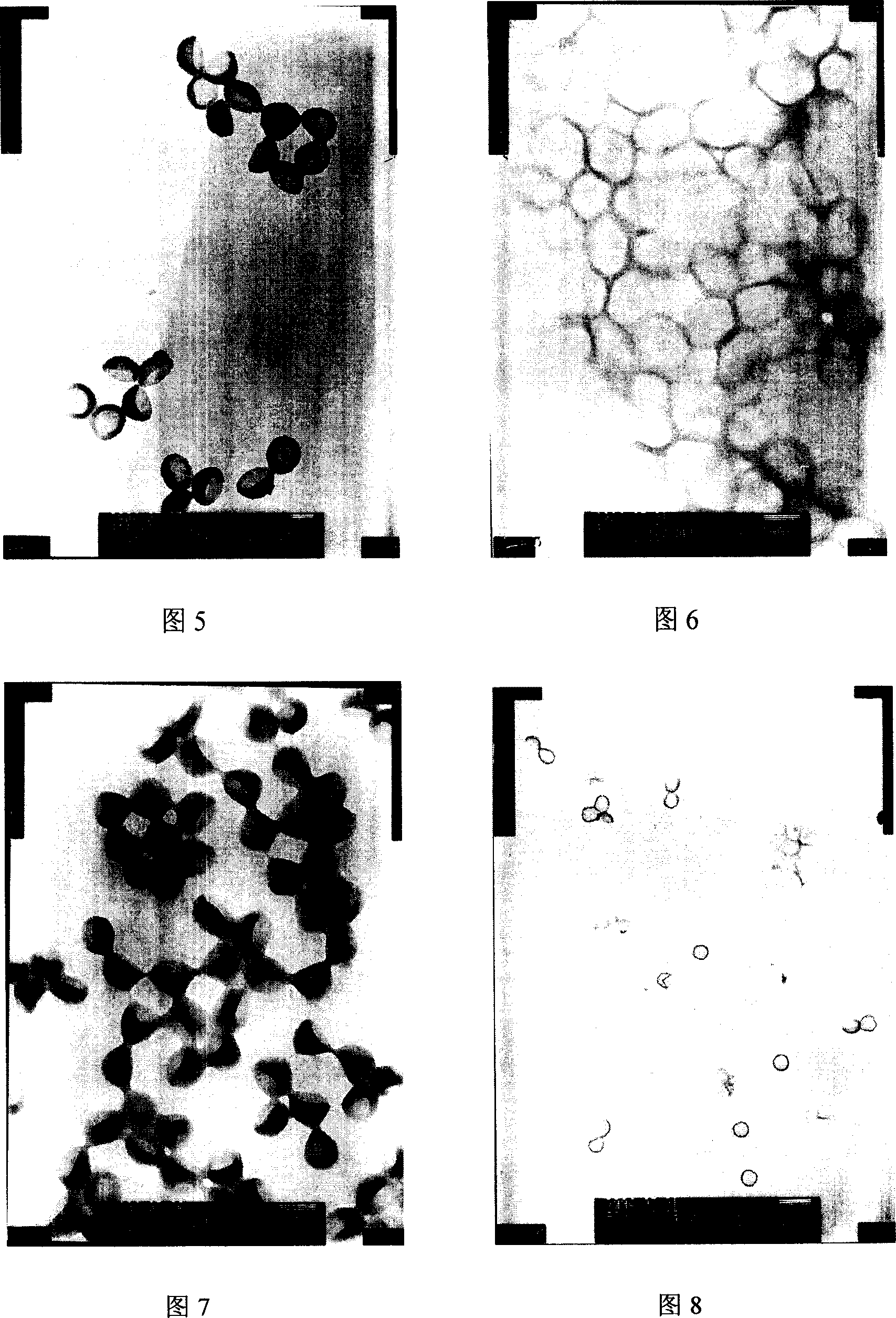

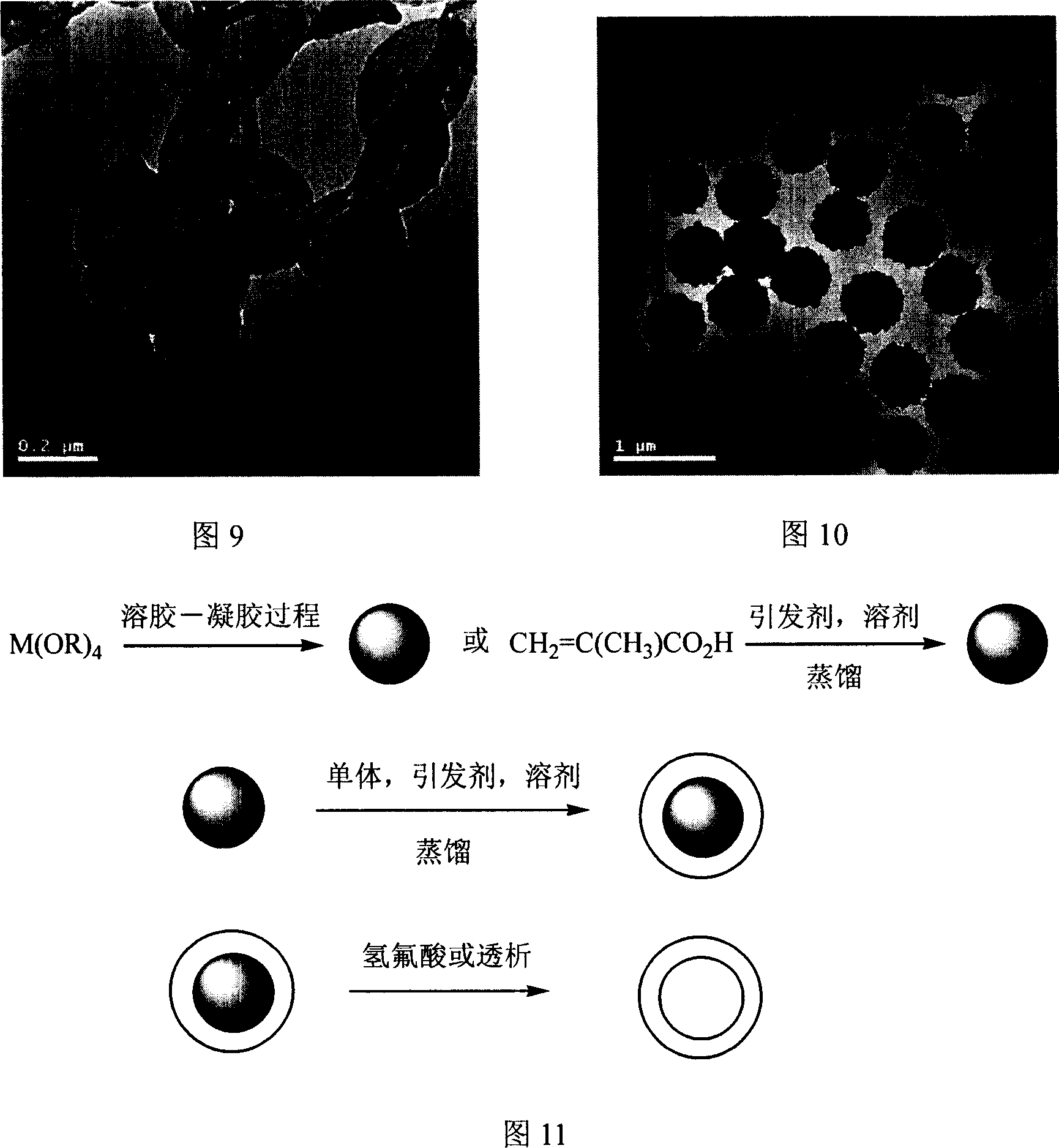

[0039] Example 1: 20mL of methacrylic acid (MAA), 0.4g of azobisisobutyronitrile (AIBN) were dispersed in 800mL of acetonitrile, put into a clean 1000mL two-necked bottle, equipped with a fractionating column, a condenser tube and a receiving bottle. The reaction flask was placed in an electric heating mantle and heated slowly, from room temperature (25° C.) to boiling within 30 minutes, and the solvent began to be evaporated. After boiling for 10 minutes, the reaction solution became cloudy. 400 mL of acetonitrile was evaporated within 2 hours to stop the reaction. Take 10mL of reaction solution, add 0.3mL divinylbenzene (DVB-80) and 0.12g AIBN, then add 30mL acetonitrile, add to a 50mL two-neck flask, install a fractionating column, a condenser tube and a receiving bottle. The reaction bottle was placed in an electric heating mantle and heated slowly, from room temperature (25°C) to boiling within 15 minutes, and controlled to evaporate 20 mL of acetonitrile within 1.5 hours...

example 2

[0040]Example 2: 20mL of methacrylic acid (MAA), 0.4g of azobisisobutyronitrile (AIBN) were dispersed in 800mL of acetonitrile, put into a clean 1000mL two-necked bottle, equipped with a fractionating column, a condenser tube and a receiving bottle. The reaction flask was placed in an electric heating mantle and heated slowly, from room temperature (25° C.) to boiling within 30 minutes, and the solvent began to be evaporated. After boiling for 10 minutes, the reaction solution became cloudy. 400 mL of acetonitrile was evaporated within 2 hours to stop the reaction. Take 10mL of the resulting reaction solution, centrifuge, pour off the supernatant, remove unreacted monomers, initiators and oligomers, disperse in 40mL of acetonitrile, add 0.2mL DVB-80 and 0.004g AIBN, put into 50mL two In the bottle, install the fractionating column, condenser tube and receiving bottle. The reaction flask was placed in an electric heating mantle and heated slowly, from room temperature (25°C) t...

example 3

[0041] Example 3: 20mL of methacrylic acid (MAA), 0.4g of azobisisobutyronitrile (AIBN) were dispersed in 800mL of acetonitrile, put into a clean 1000mL two-necked bottle, equipped with a fractionating column, a condenser tube and a receiving bottle. The reaction flask was placed in an electric heating mantle and heated slowly, from room temperature (25° C.) to boiling within 30 minutes, and the solvent began to be evaporated. After boiling for 10 minutes, the reaction solution became cloudy. 400 mL of acetonitrile was evaporated within 2 hours to stop the reaction. Get the reaction liquid 10mL of gained, centrifuge, incline supernatant liquid, remove unreacted monomer, initiator and oligomer, disperse in 40mL acetonitrile, add 0.3mL DVB-80 and 0.3mL methyl methacrylate ( MMA) was added into a 50mL two-necked flask, and the temperature was raised to boiling in 15 minutes, and 20mL of acetonitrile was evaporated within 1.5 hours. The reaction solution was centrifuged to pour o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com