Spinel Li1+xMyMn2-x-yO4, preparation method thereof and lithium-ion secondary battery

A xmymn2-x-yo4, spinel technology, applied in the field of doping spinel lithium manganate, can solve the problems of irregular lithium manganate morphology, reduced material cycle performance, low material specific capacity, etc. Excellent cycle performance, high temperature cycle performance and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention simultaneously provides above-mentioned spinel Li 1+x m y mn 2-x-y o 4 methods of preparation, including

[0038] (1) Mixing materials: mix lithium-containing compound, manganese powder and / or manganese-containing compound, and dopant element-containing compound uniformly according to the chemical dosage ratio, add solvent and stir well, transfer to ball milling tank for ball milling, dry and remove solvent, and obtain mixed raw materials;

[0039] (2) Carrying out high-temperature sintering of the mixed raw material obtained in step (1) under an atmosphere containing oxygen;

[0040] (3) Li obtained from step (2) 1+x m y mn 2-x-y o 4 The precursor is annealed and sintered at low temperature in an atmosphere containing oxygen; cooling to obtain Li 1+x m y mn 2-x-y o 4 . The preparation method of the invention is simple, low in cost and easy to realize. The prepared spinel lithium manganese oxide is widely used, and the performance of ...

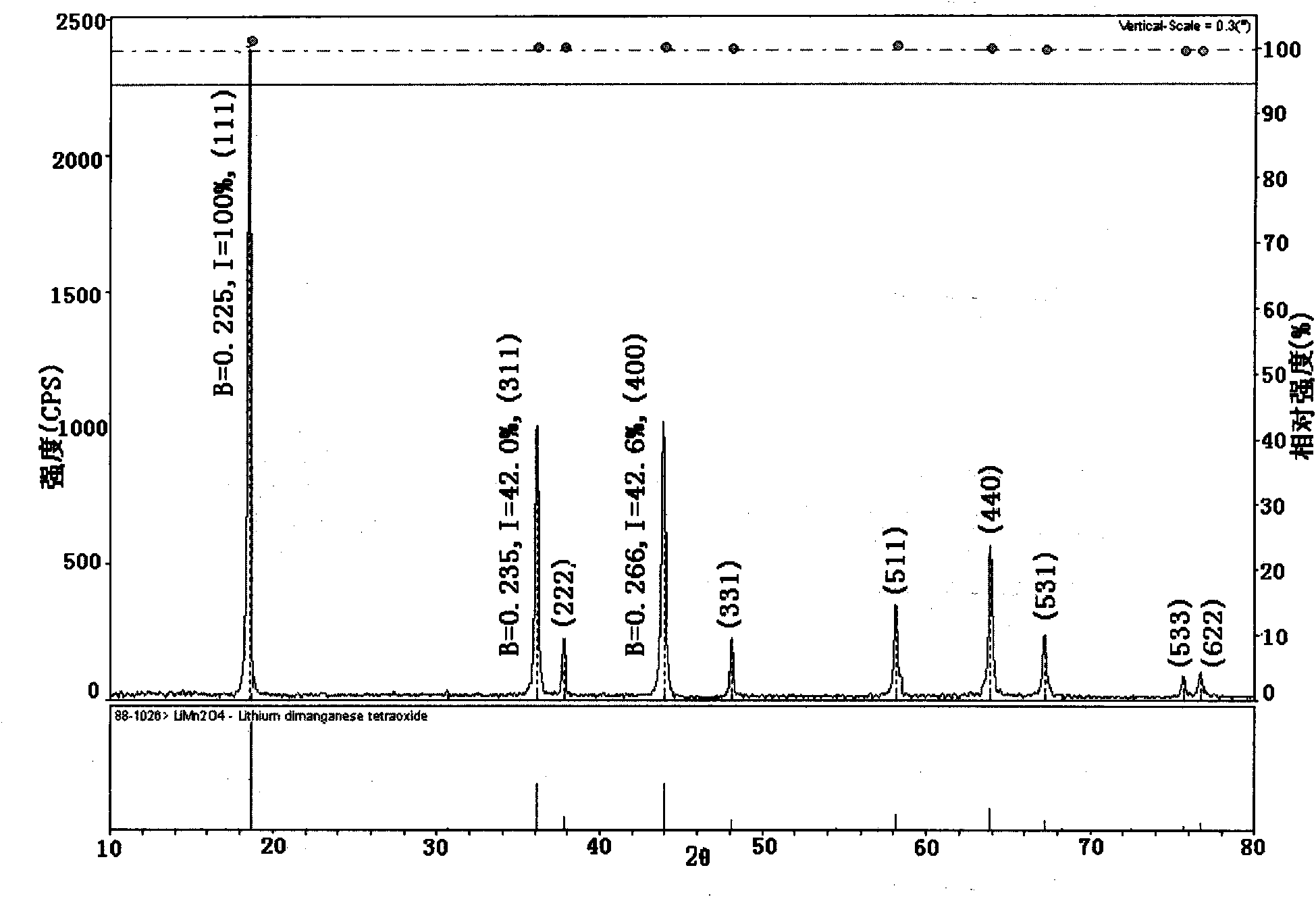

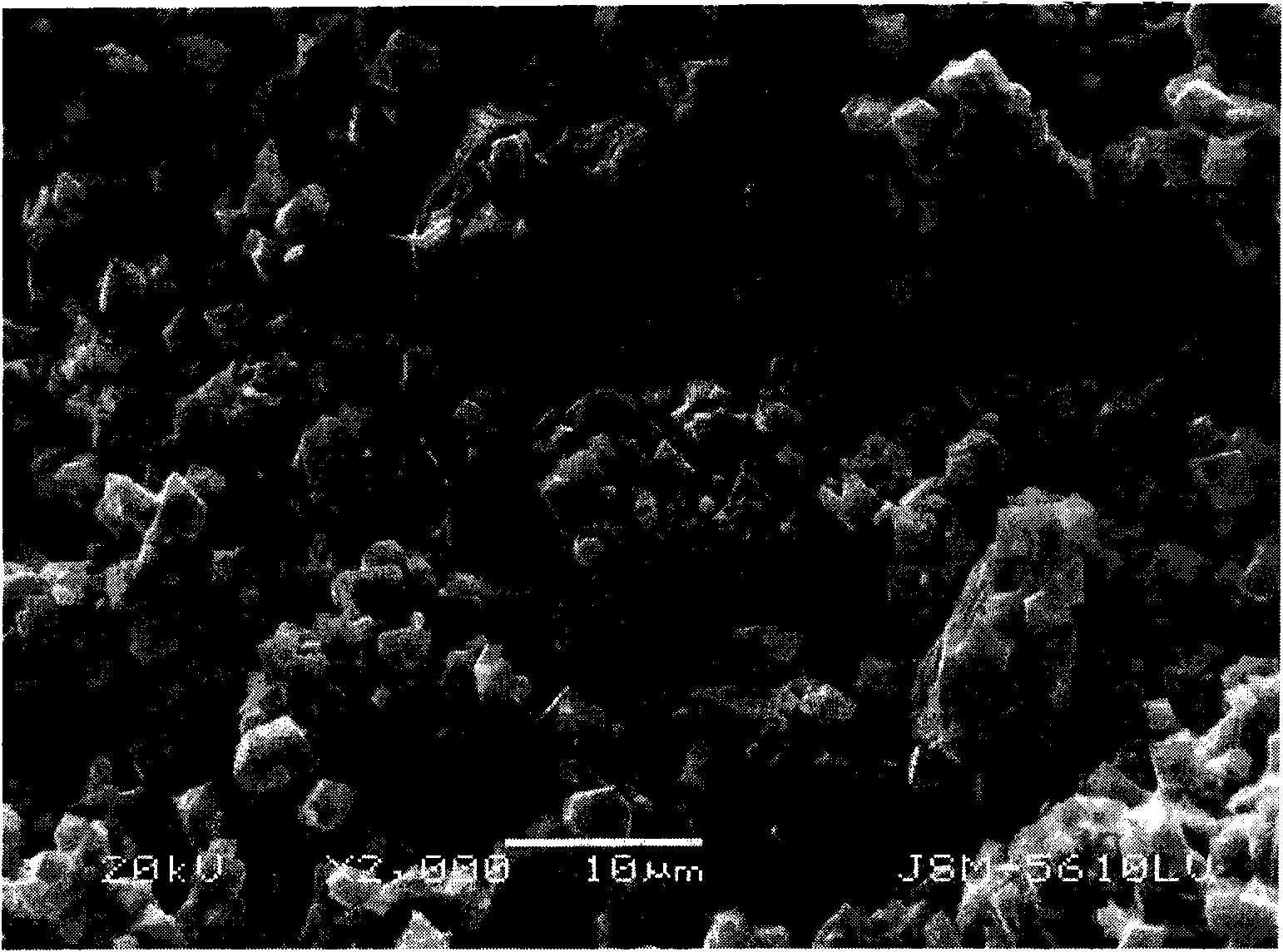

Embodiment 1

[0055] (1) Preparation of cathode material

[0056] 340g lithium carbonate (battery grade), 1400g electrolytic manganese dioxide, 70.22g cobalt nitrate (21% cobalt content), 95.32g aluminum nitrate nonahydrate (battery grade), and 825g deionized water were added to a 5L stirring tank, and stirred After 1.5h, transfer to the ball mill tank of 5L, the control ball-to-material ratio is 1: 1, on the planetary ball mill with the speed ball mill of 150 revs / min 2h, the material after the ball mill is on the rake type vacuum drier (self-made, Negative pressure 0.05Mpa) Dry at 150°C for 4 hours and take it out. The dried material is first heated to 650°C at a rate of 5°C / min in the muffle furnace, kept at a constant temperature for 6 hours, then raised to 900°C at a rate of 3°C / min, kept at a constant temperature for 12 hours, and then heated at a rate of 5°C / min Cool down to 700°C, keep the temperature constant for 8 hours, then cool down to 500°C at a rate of 5°C / min, hold the temp...

Embodiment 2

[0070] The synthesis method and the battery manufacturing method are the same as in Example 1, except that the raw materials for the preparation of the positive electrode material contain 10.0 g of anhydrous sodium carbonate (analytical pure) and 5.2 g of magnesium nitrate hexahydrate (analytical pure).

[0071] Measure the I of material according to the method identical with embodiment 1 400 / I 311 ; 111,311, half width B value, I of 400 peak crystal plane diffraction peaks 311 / I 111 , I 400 / I 111 The data is shown in Table 1; the primary particle diameter is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com