Multi-mixed and coated high compaction density silicon carbon anode material and preparation method thereof

A negative electrode material and multiple mixing technology, applied in the direction of battery electrodes, secondary batteries, electrical components, etc., can solve the problems of uneven carbon coating, difficulty in completeness, difficulty in increasing the compaction density of silicon carbon negative electrodes, etc., and achieve high pressure Solid density, simple preparation method, beneficial to large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

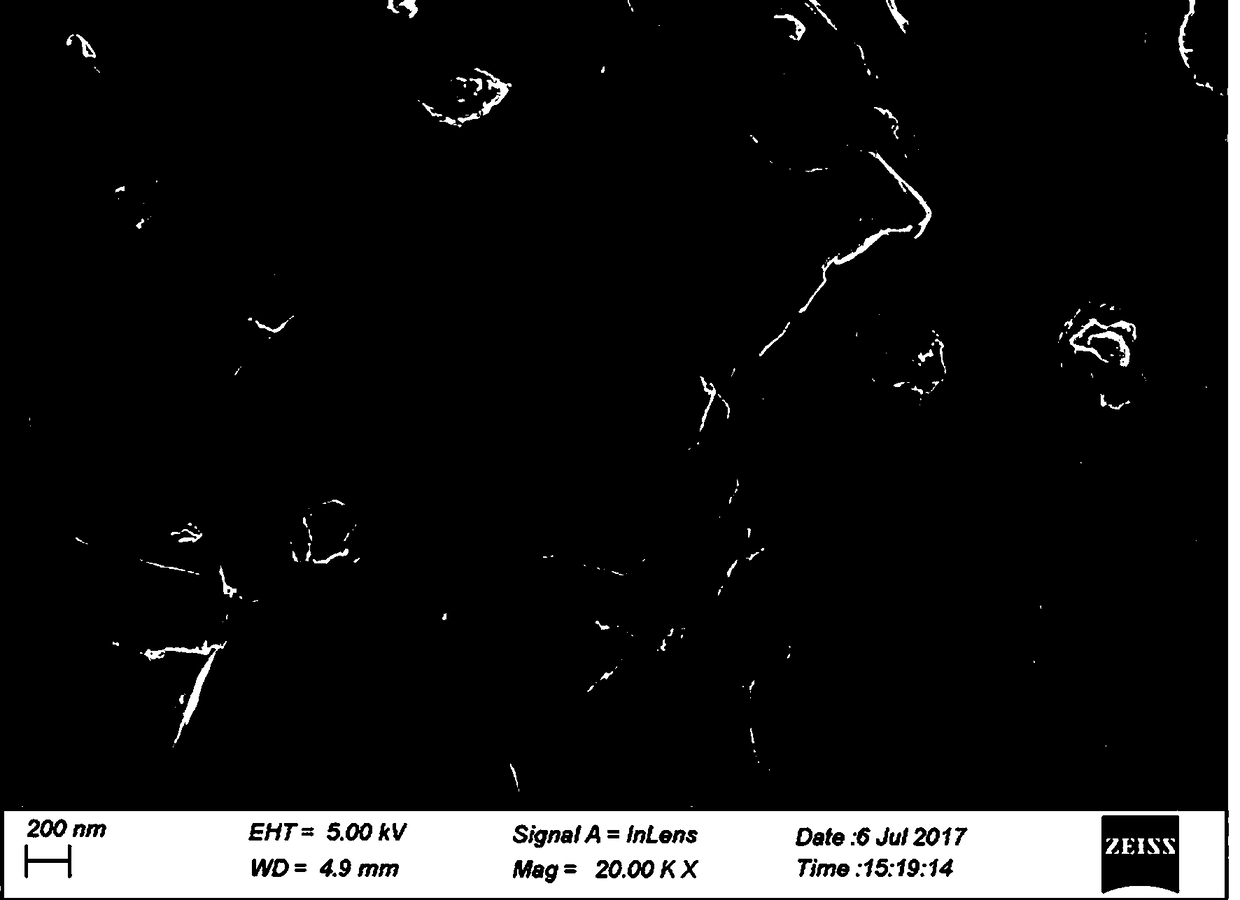

Embodiment 1

[0036] The silicon powder and aluminum powder with an average particle size of 1um are wet-milled under a high-energy ball mill. The mass ratio of silicon powder to aluminum powder is 4:1, the speed of the ball mill is 700r / min, and the ball is milled for 5 hours to obtain a uniformly mixed slurry. After the solvent is calcined at 900°C under a nitrogen atmosphere, the sintering time is 10h. The obtained silicon powder powder is ground, sieved, and added to the alcohol solvent containing PVP. Ketjen Black is added under stirring conditions. The mass ratio of silicon powder, Ketjen Black, and PVP is 80:5:64. The solvent was evaporated, and the solid powder was obtained by calcination at 800°C for 3 hours under a nitrogen atmosphere; the obtained solid powder was added to a 1M HCl solution, stirred for 5 hours, filtered with suction, and dried to obtain primary particles; the primary particles were ground and screened. The medium-temperature coal-based pitch is added to the react...

Embodiment 2

[0039] The silicon powder and magnesium powder with an average particle size of 500nm are wet-milled under a high-energy ball mill. The mass ratio of silicon powder to magnesium powder is 9:1, the speed of the ball mill is 500r / min, and the ball mill is 10h to obtain a uniformly mixed slurry. After the solvent is calcined under a nitrogen atmosphere at 1000°C, the sintering time is 5h. The obtained silicon powder powder is ground, sieved, and added to the alcohol solvent containing polyacrylic acid, and acetylene black is added under stirring conditions. The mass ratio of silicon powder, acetylene black and polyacrylic acid is 70:5:55. Evaporate the solvent and calcinate at 1000°C for 3 hours under a nitrogen atmosphere to obtain a solid powder; add the obtained solid powder to 5M H 2 SO 4 In the solution, stir for 10 hours and then filter with suction. After drying, the primary particles are obtained; the primary particles are ground and sieved. Put the medium temperature coal...

Embodiment 3

[0042] The silicon powder and iron powder with an average particle diameter of 100nm are wet-milled in a high-energy ball mill. The mass ratio of silicon powder to iron powder is 4:1, the speed of the ball mill is 700r / min, the ball mill is 5h, and nitrogen is protected to obtain a uniformly mixed After evaporating the solvent, the slurry is calcined at 1000°C under a nitrogen atmosphere, and the sintering time is 2h. The obtained solid powder is ground and sieved, and added to an aqueous solvent containing glucose and chitosan. One-armed carbon nanotubes are added under stirring. The mass ratio of solid powder, one-armed carbon nanotubes, glucose and chitosan is 75: 3:30:30. Evaporate the solvent and calcinate at 1000°C for 3 hours under a nitrogen atmosphere to obtain a solid powder; add the obtained solid powder to 5M H 2 SO 4 In the solution, stir for 5 hours and filter with suction. After drying, the primary particles are obtained; the primary particles are ground and siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com