Electrolyte of considering high temperature cycle performance and low temperature cycle performance of battery and lithium-ion battery

A high-low temperature cycle, lithium-ion battery technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of conductivity, cycle and high temperature performance, and can not optimize the function of battery materials, etc., to broaden the use temperature range, Good cycle performance and enhanced competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

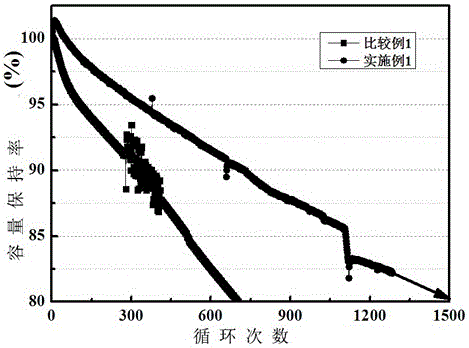

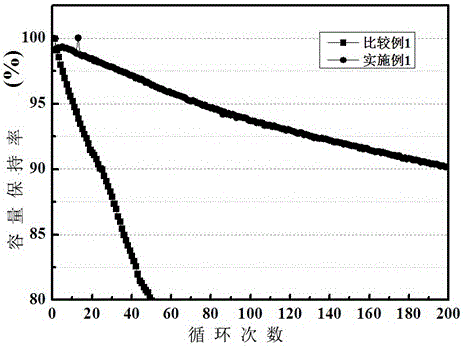

Examples

Embodiment 1

[0019] (1) Electrolyte preparation: according to EC (ethylene carbonate): PC (propylene carbonate): DEC (diethyl carbonate): EMC (methyl ethyl carbonate): VC (vinylene carbonate): PS ( Propylene sulfite) = 35:5:35:25:2:2.5 volume ratio, prepare the electrolyte solution with lithium salt concentration of 1mol / L, wherein EC, PC, DEC and EMC are non-aqueous solvents, VC and PS are Additive, lithium salt is the composition of following structural formula:

[0020] .

[0021] (2) Preparation of cathode material: LiFePO mixed with 91% by weight 4 (positive active material), 4% by weight of SP (superconducting carbon black) and 5% by weight of PVDF (binder), and adding N-methylpyrrolidone to it to make a slurry, the The slurry is coated on an aluminum foil, and rolled after drying to obtain the positive electrode material.

[0022] (3) Preparation of negative electrode material: mixing 75% by weight of artificial graphite, 20% by weight of mesophase carbon microspheres, and 5% b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com