Preparation method of nitrogen-doped silicon/carbon core-shell structure lithium-ion battery negative electrode material

A technology for lithium ion batteries and negative electrode materials, applied in the field of materials science, can solve problems such as conductive network damage, electrode pulverization, carbon layer cracking, etc., and achieve the effects of improved cycle performance, low cost, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

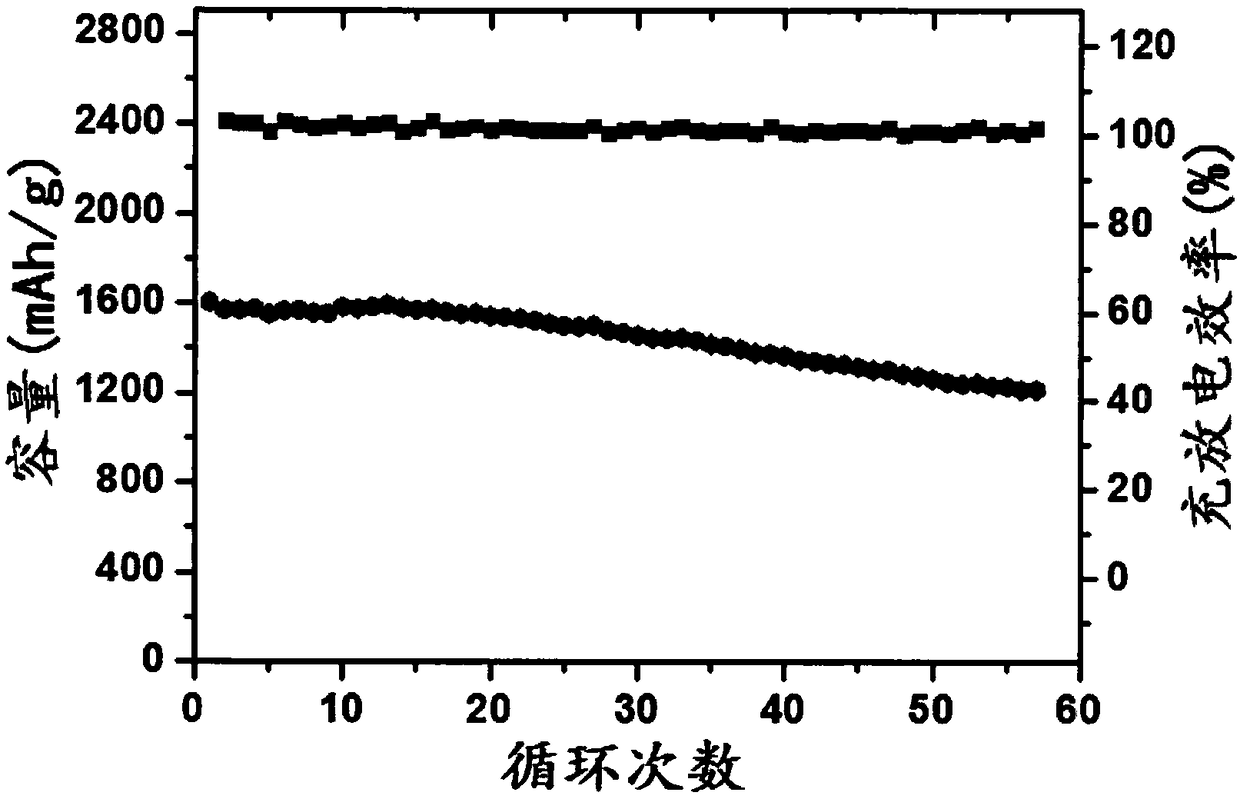

[0023] A preparation method of nitrogen-doped silicon / carbon core-shell structure lithium ion battery negative electrode material, according to the mass ratio of melamine and polyacrylonitrile, according to the mass ratio of 1:10, successively dissolved in N,N-dimethylformamide solvent to prepare Precursor sheath liquid; silicon nanoparticles and polyvinylpyrrolidone are respectively dissolved in N,N-dimethylformamide solvent, stirred and ultrasonically stirred, and the two are mixed and stirred to form a precursor core liquid. The precursor fiber was obtained by coaxial electrospinning method, followed by high-temperature carbonization treatment to prepare the silicon@carbon / carbon nanofiber core-shell structure lithium-ion battery electrode material with nitrogen-doped internal carbon network connection.

[0024] The preparation method of the silicon@carbon / carbon nanofiber core-shell structure lithium-ion battery negative electrode material with nitrogen-doped internal carbo...

Embodiment 2

[0030] A nitrogen-doped silicon / carbon core-shell structure lithium-ion battery negative electrode material, calculated by mass ratio, that is, polyacrylonitrile and polypyrrole at a ratio of 10:1, successively dissolved in N,N-dimethylformamide solvent The precursor sheath liquid is prepared; the ratio of silicon nanoparticles and polyvinylpyrrolidone is 6:1, respectively dissolved in N, N-dimethylformamide solvent to prepare the precursor core liquid. A silicon@carbon / carbon nanofiber core-shell structure lithium-ion battery electrode material with nitrogen-doped internal carbon network interconnection was prepared by coaxial electrospinning method and high-temperature carbonization treatment.

[0031] The preparation method of the above-mentioned nitrogen-doped silicon / carbon core-shell structure lithium-ion battery negative electrode material specifically includes the following steps:

[0032] (1) Preparation of precursor solution

[0033]At room temperature, accurately w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com