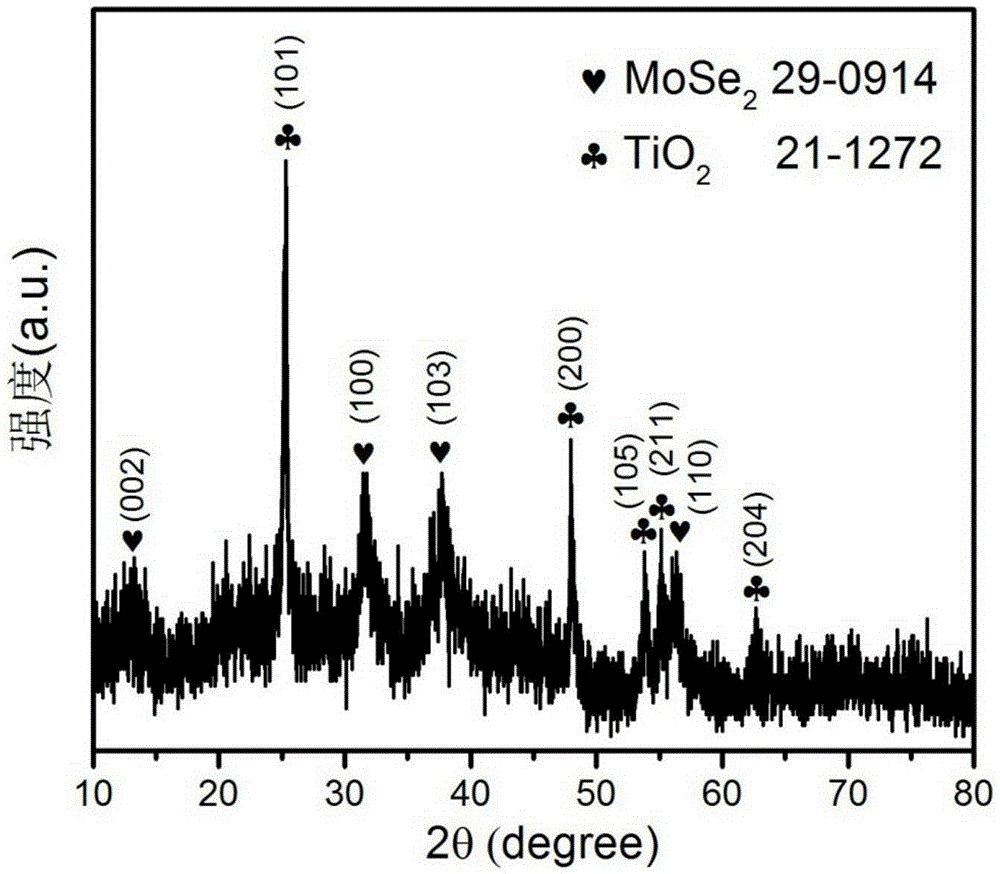

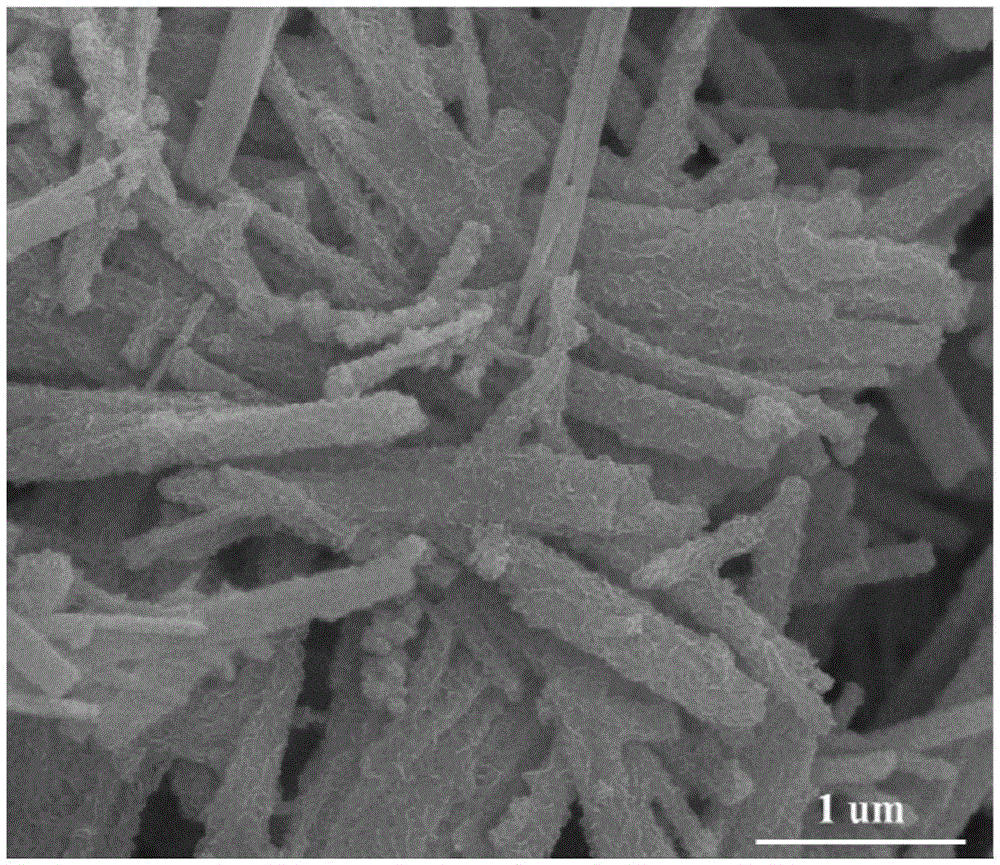

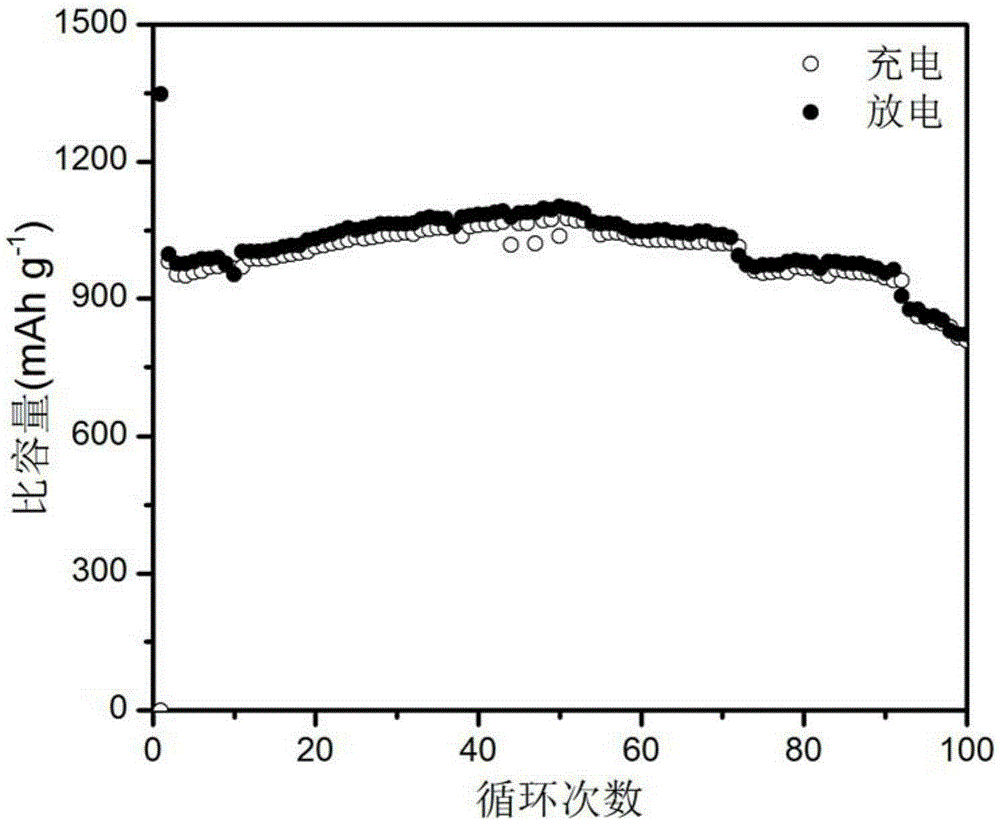

Molybdenum diselenide/titanium dioxide composite material and preparation method and application therefor

A technology of titanium dioxide and molybdenum diselenide is applied in electrical components, battery electrodes, circuits, etc., to achieve the effects of simple and controllable preparation method, reasonable structure and uniform product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1) Add a volume of 66mL of 10mol / L sodium hydroxide concentrated alkali to 100mL of polytetrafluoroethylene lining, then add 0.66g of titanium dioxide (anatase phase) powder (particle size is 25nm), stir until uniformly mixed, A white cloudy suspension was formed;

[0054] 2) Seal the polytetrafluoroethylene liner into the autoclave, start heating in a closed drying oven and heat the reaction at 180°C for 24h;

[0055] 3) After the reaction is completed, cool down to room temperature with the furnace, and then obtain the original product by vacuum filtration, and dry it in a drying oven at 60°C for 8 hours;

[0056] 4) Soak the sample dried in step 3) in 0.1mol / L dilute hydrochloric acid for 24 hours, wash it with deionized water by centrifugation until it is neutral, and then dry it in a drying oven;

[0057] 5) Place the sample obtained in step 4) in a corundum ark, start heating in a muffle furnace, heat at 500°C for 2h, and cool to room temperature with the furnace...

Embodiment 2

[0066] 1) Add a volume of 66mL of 10mol / L sodium hydroxide concentrated alkali to 100mL of polytetrafluoroethylene lining, then add 0.66g of titanium dioxide (anatase phase) powder (particle size is 25nm), stir until uniformly mixed, A white cloudy suspension was formed;

[0067] 2) Seal the polytetrafluoroethylene liner into the autoclave, start heating in a closed drying oven and heat the reaction at 180°C for 24h;

[0068] 3) After the reaction is completed, cool down to room temperature with the furnace, and then obtain the original product by vacuum filtration, and dry it in a drying oven at 60°C for 8 hours;

[0069] 4) Soak the sample dried in step 3) in 0.1mol / L dilute hydrochloric acid for 24 hours, wash it with deionized water by centrifugation until it is neutral, and then dry it in a drying oven;

[0070] 5) Place the sample obtained in step 4) in a corundum ark, start heating in a muffle furnace, heat at 500°C for 2h, and cool to room temperature with the furnace...

Embodiment 3

[0077] 1) Add a volume of 66mL of 10mol / L sodium hydroxide concentrated alkali to 100mL of polytetrafluoroethylene lining, then add 0.66g of titanium dioxide (anatase phase) powder (particle size is 25nm), stir until uniformly mixed, A white cloudy suspension was formed;

[0078] 2) Seal the polytetrafluoroethylene liner into the autoclave, start heating in a closed drying oven and heat the reaction at 180°C for 24h;

[0079] 3) After the reaction is completed, cool down to room temperature with the furnace, and then obtain the original product by vacuum filtration, and dry it in a drying oven at 60°C for 8 hours;

[0080] 4) Soak the sample dried in step 3) in 0.1mol / L dilute hydrochloric acid for 24 hours, wash it with deionized water by centrifugation until it is neutral, and then dry it in a drying oven;

[0081] 5) Place the sample obtained in step 4) in a corundum ark, start heating in a muffle furnace, heat at 500°C for 2h, and cool to room temperature with the furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com