Non-aqueous electrolyte solution and lithium ion battery using same

A non-aqueous electrolyte, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low temperature performance and cycle performance, low temperature resistance, propylene carbonate intercalation damage and other problems, to achieve cycle performance Good, good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention also provides a preparation method of non-aqueous electrolyte

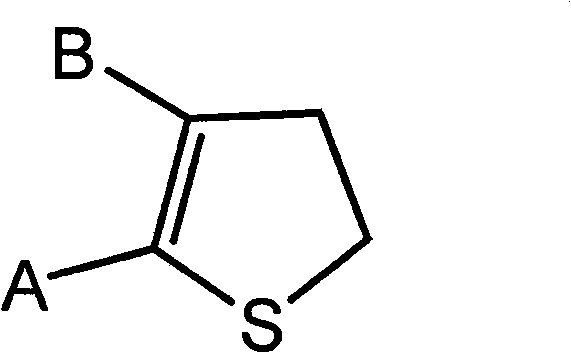

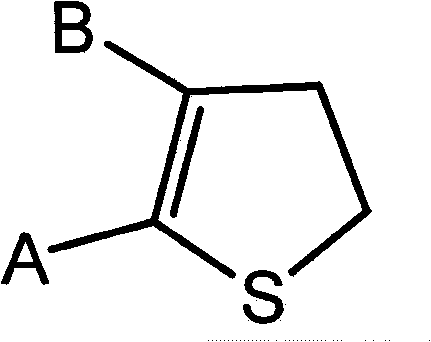

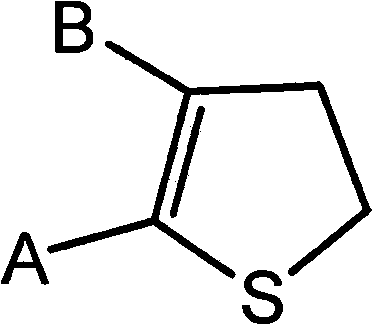

[0022] The method comprises mixing an organic solvent and an additive, and then adding a lithium salt to obtain a non-aqueous electrolyte, and the additive is one or more of hydrothiophenes having the following structure:

[0023]

[0024] A and B are independently selected from one of amino, alkyl, halogen, and ester groups. In the process of configuring the non-aqueous electrolyte, based on the total weight of the non-aqueous electrolyte, lithium salts, organic solvents, and additives The weight ratio of the lithium salt, the organic solvent and the additive is 3-20:70-90:0.5-10; preferably, the weight ratio of the lithium salt, the organic solvent and the additive is 5-15:70-85:0.5-5.

[0025] The detailed steps are to first mix ethyl methyl carbonate, dimethyl carbonate, diethyl carbonate, ethylene carbonate, propylene carbonate, butylene carbonate, vinyl sulfite, propylene sulf...

Embodiment 1

[0028] This example is used to illustrate the non-aqueous electrolytic solution provided by the present invention, its preparation method and the lithium ion battery using the non-aqueous electrolytic solution.

[0029] 1) Preparation of non-aqueous electrolyte: Based on the total weight of non-aqueous electrolyte, put 30 parts of propyl carbonate (PC), 40 parts of ethyl butyrate (EB), and 30 parts of dimethyl carbonate (DMC) into Mix the high mixer for 1 hour at a speed of 50r / min to make a mixed organic solvent, then add 18 parts of lithium salt LiPF 6, and then add 0.5% of 2-aminohydrothiophene and 0.3% of 2-fluorohydrothiophene based on the total weight of the non-aqueous electrolyte, and after stirring for 2h at a stirring speed of 50r / min, the required non-aqueous electrolyte sample A1.

[0030] 2) Preparation of negative electrode: natural graphite, conductive agent acetylene black, binder PVDF (Atofina Company, 761#PVDF) in the solvent N-methyl-2-pyrrolidone in a cert...

Embodiment 2

[0034] This example is used to illustrate the non-aqueous electrolytic solution provided by the present invention, its preparation method and the lithium ion battery using the non-aqueous electrolytic solution.

[0035] 1) Preparation of non-aqueous electrolyte: Based on the total weight of non-aqueous electrolyte, put 30 parts of propyl carbonate (PC), 40 parts of ethyl butyrate (EB), and 30 parts of dimethyl carbonate (DMC) into Mix the high mixer for 1 hour at a speed of 50r / min to make a mixed organic solvent, then add 18 parts of lithium salt LiPF 6 , followed by adding 1.5 wt% 2-aminohydrothiophene and 0.9% 2-fluorohydrothiophene based on the total weight of the non-aqueous electrolyte, and stirring for 2 hours, the required non-aqueous electrolyte sample A2 was prepared.

[0036] 2) Preparation of negative electrode: natural graphite, conductive agent acetylene black, binder PVDF (Atofina Company, 761#PVDF) in the solvent N-methyl-2-pyrrolidone in a certain ratio of 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com