Black-phosphorus-based composite negative electrode material and preparing method thereof

A technology of negative electrode material and black phosphorus, which is applied in the field of black phosphorus-based composite negative electrode material and its preparation, can solve the problems of poor coulombic efficiency, rapid capacity decay and low capacity retention rate of black phosphorus electrode material, so as to solve the problem of poor cycle performance, The effect of low cost and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

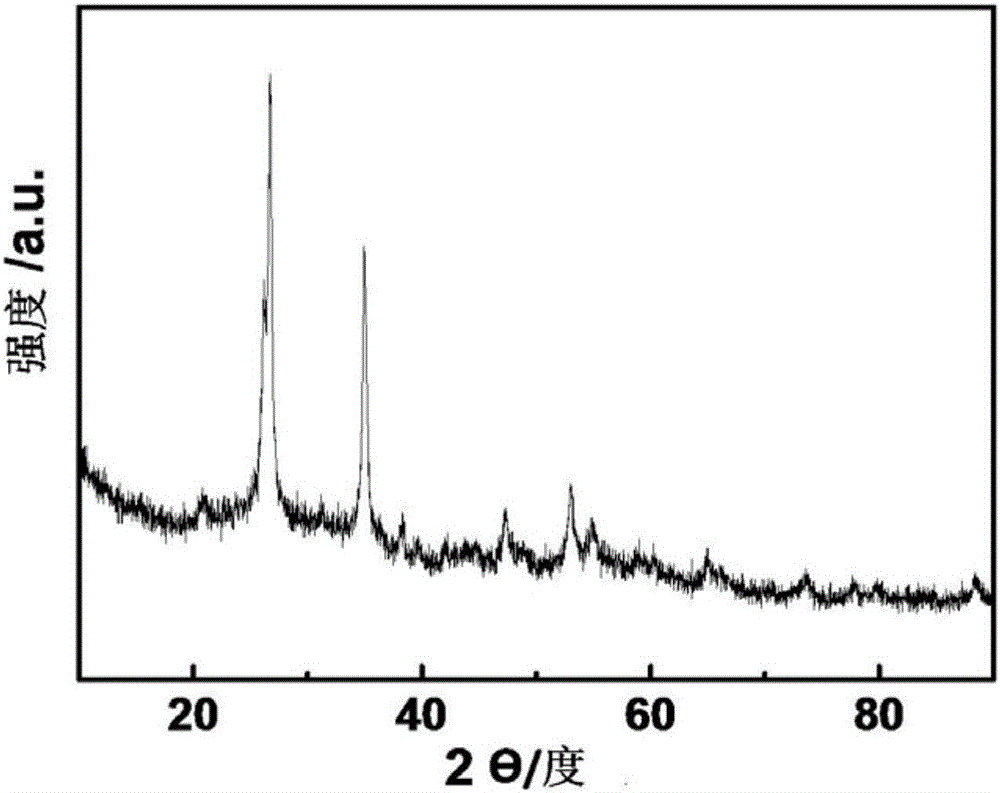

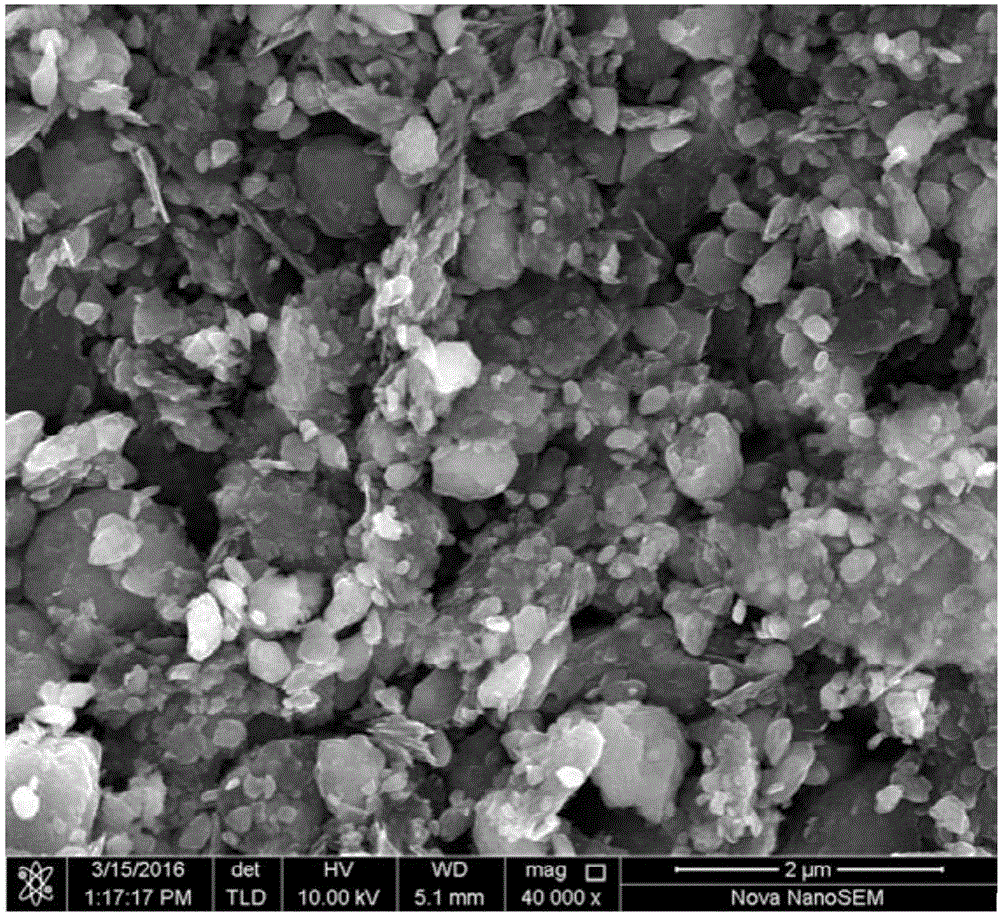

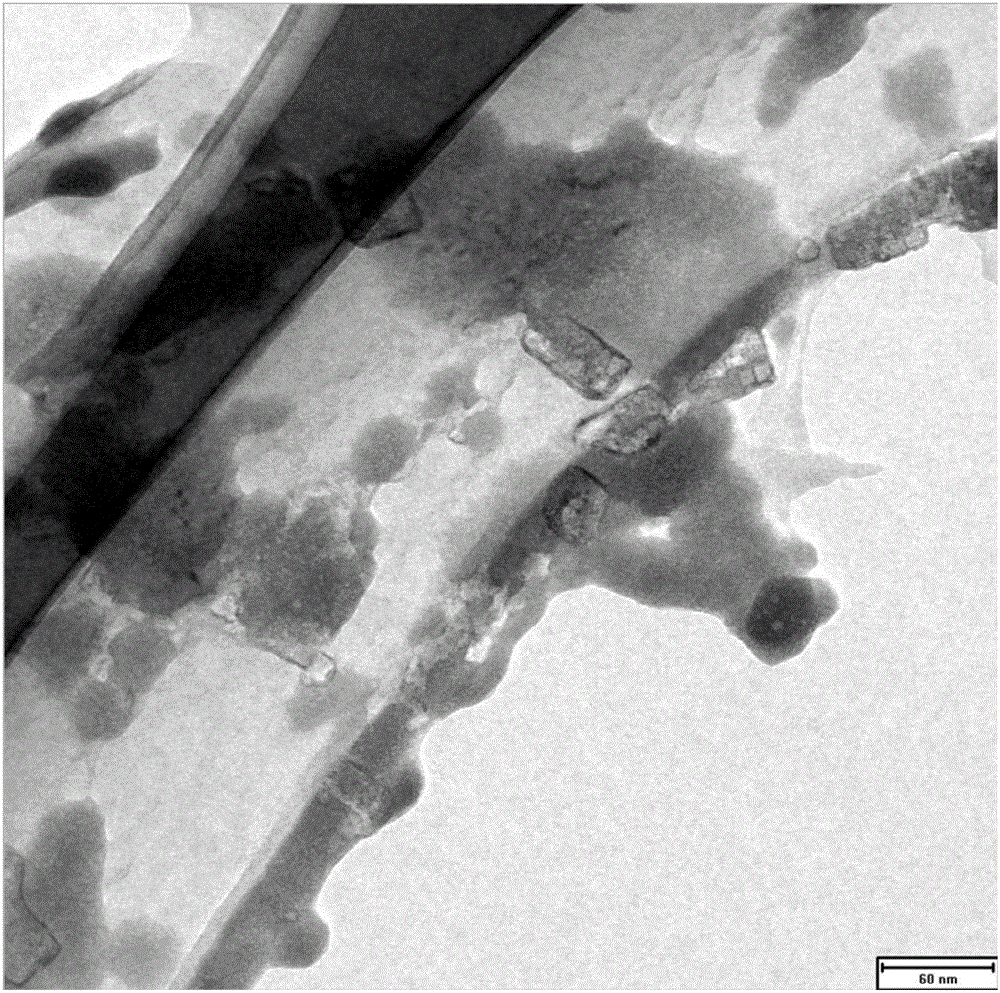

[0036] In this embodiment, a black phosphorus-based composite negative electrode material is prepared by ball milling (wherein, red phosphorus: germanium oxide = 2:1, and the amount of graphite added is 50% of the total mass of the three raw materials of red scale, germanium oxide and graphite). The mass ratio of black scale, germanium oxide and graphite is 2:1:3.

[0037] The preparation method is as follows:

[0038] (1) Weigh 2 parts of red phosphorus powder and 1 part of germanium oxide powder, mix the two to obtain a mixture, and then add the mixture to a stainless steel ball mill tank for the first ball milling to obtain the first ball milling product; The ball-to-material ratio is 20:1 (that is, adding 60 parts of stainless steel balls), the rotating speed is 300rpm / min, and the ball milling time is 20h;

[0039] (2) take by weighing 3 parts of graphite powder, add in the ball milling product that step (1) obtains for the first time, then carry out ball milling for the...

Embodiment 2

[0044] In this example, a black phosphorus-based composite negative electrode material is prepared by ball milling (wherein, red phosphorus: germanium oxide = 0.25:1, and the amount of graphite added is 50% of the total mass of the three raw materials of red scale, germanium oxide and graphite). The mass ratio of black scale, germanium oxide and graphite is 0.25:1:1.25.

[0045] The preparation method is as follows:

[0046] (1) Weigh 1 part of red phosphorus powder and 4 parts of germanium oxide powder, mix the two to obtain a mixture, then add the mixture to a stainless steel ball mill tank for the first ball mill to obtain the first ball mill product; The ball-to-material ratio is 20:1 (that is, adding 100 parts of stainless steel balls), the rotating speed is 300rpm / min, and the ball milling time is 20h;

[0047] (2) take by weighing 5 parts of graphite powder, add in the ball milling product that step (1) obtains for the first time, then carry out ball milling for the se...

Embodiment 3

[0050] In this example, a black phosphorus-based composite negative electrode material is prepared by ball milling (where red phosphorus: germanium oxide = 2:1, and the amount of graphite added is 80% of the total mass of red scale, germanium oxide and graphite). The mass ratio of black scale, germanium oxide and graphite is 2:1:12.

[0051] The preparation method is as follows:

[0052] (1) Weigh 2 parts of red phosphorus powder and 1 part of germanium oxide powder, mix the two to obtain a mixture, and then add the mixture to a stainless steel ball mill tank for the first ball milling to obtain the first ball milling product; The ball-to-material ratio is 20:1 (that is, adding 60 parts of stainless steel balls), the rotating speed is 300rpm / min, and the ball milling time is 20h;

[0053] (2) take by weighing 12 parts of graphite powder, add in the ball milling product that step (1) obtains for the first time, then carry out ball milling for the second time, the product obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com