Preparation method of Cu2O/Cu/PPy nanowire composite lithium ion battery negative material

A technology for ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low conductivity and small specific capacity, achieve high specific capacity, improve cycle performance and capacity, and achieve good cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare 0.1 mol / L pyrrole monomer solution and 0.05 mol / L copper acetate solution, and ultrasonically disperse them evenly. Take 10mL of the prepared pyrrole monomer solution and mix it with 65mL of the prepared copper acetate solution, and transfer it to a hydrothermal reaction kettle; place the hydrothermal reaction kettle in an oven, set the temperature to 160°C, and react for 12h; The product obtained by the reaction was washed by centrifugation, and dried at 50 °C for 12 h, and the obtained Cu 2 O / Cu / PPy nanowires were assembled into a button lithium-ion battery, and the electrical properties were analyzed and characterized.

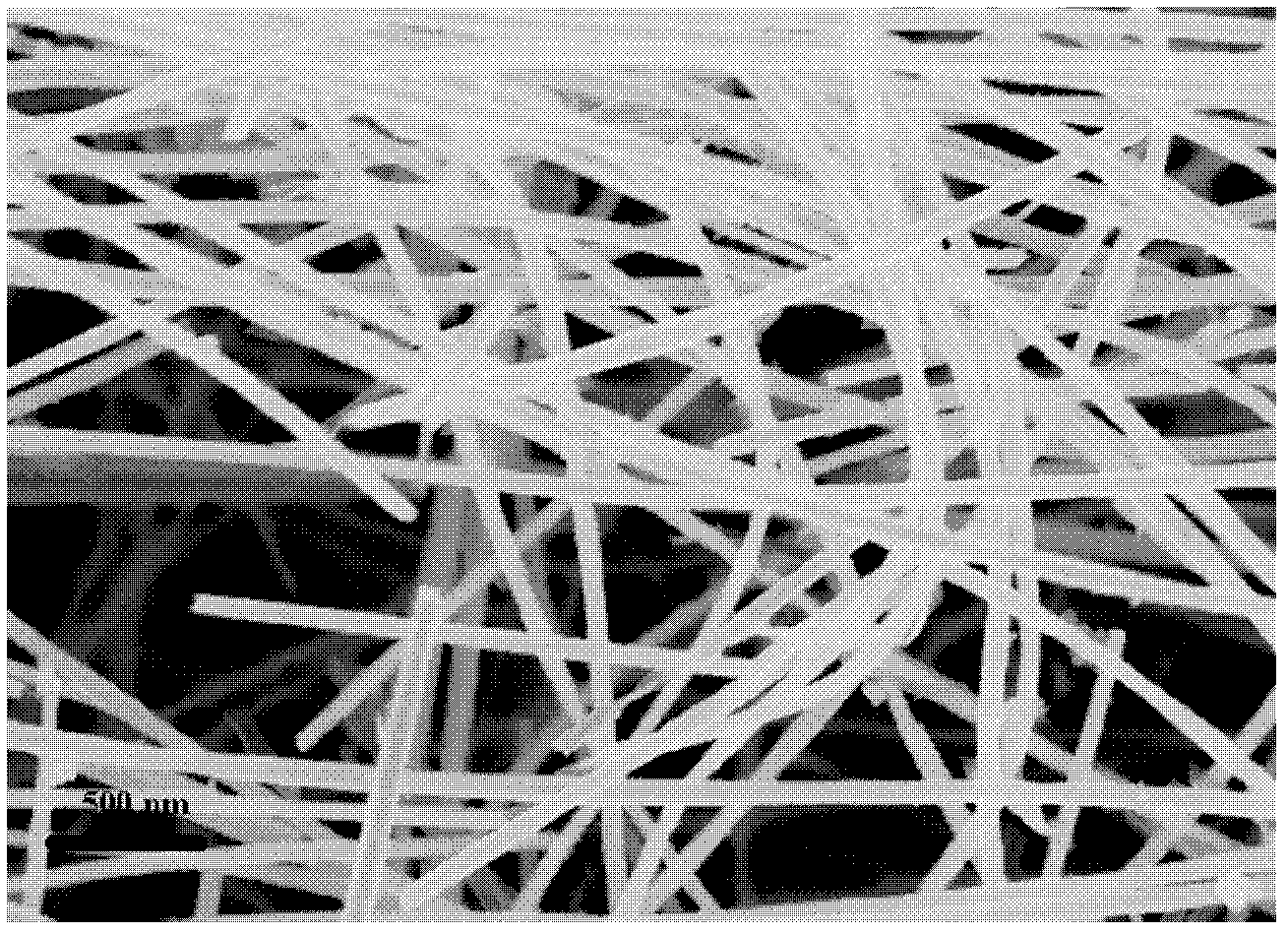

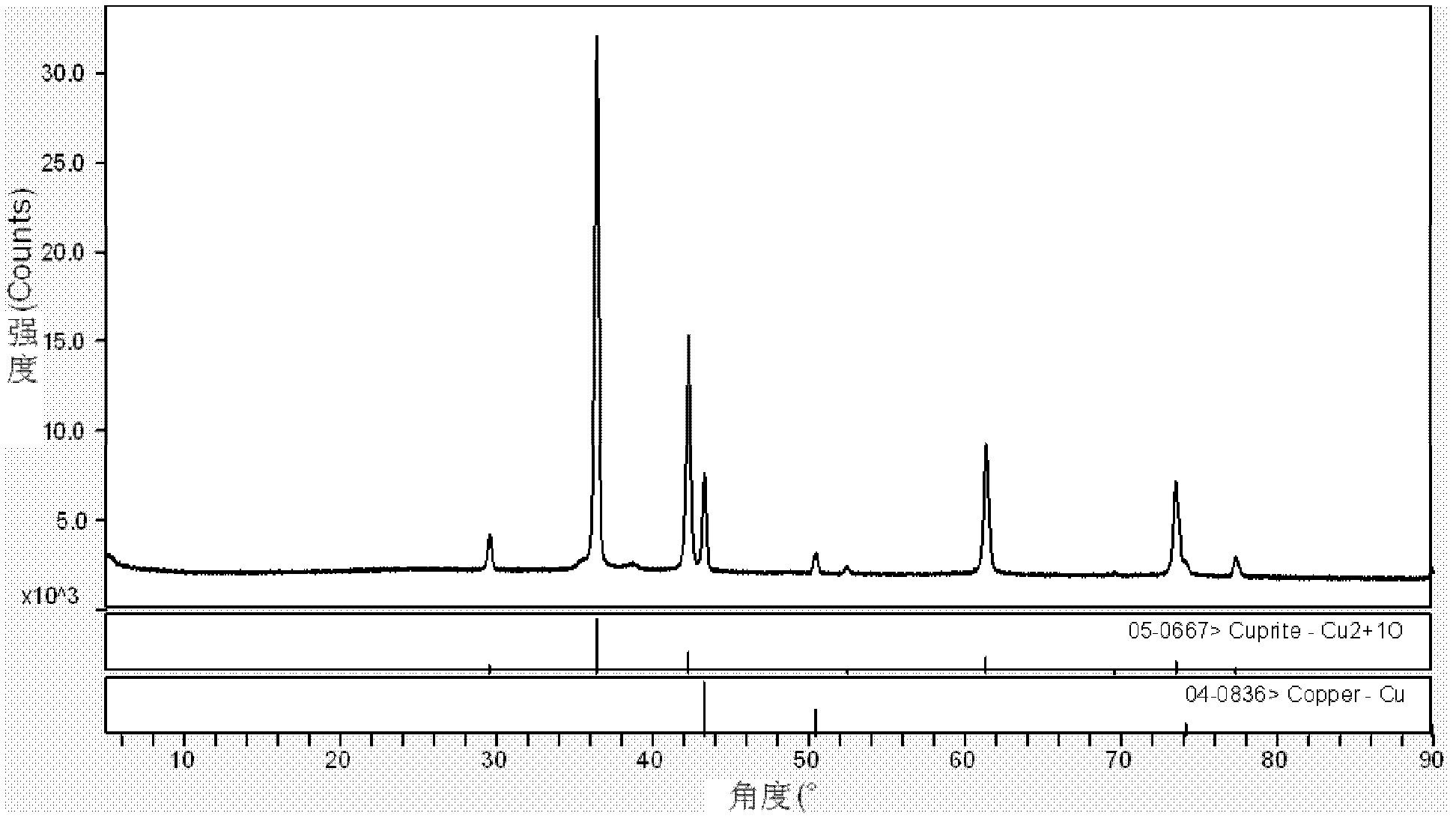

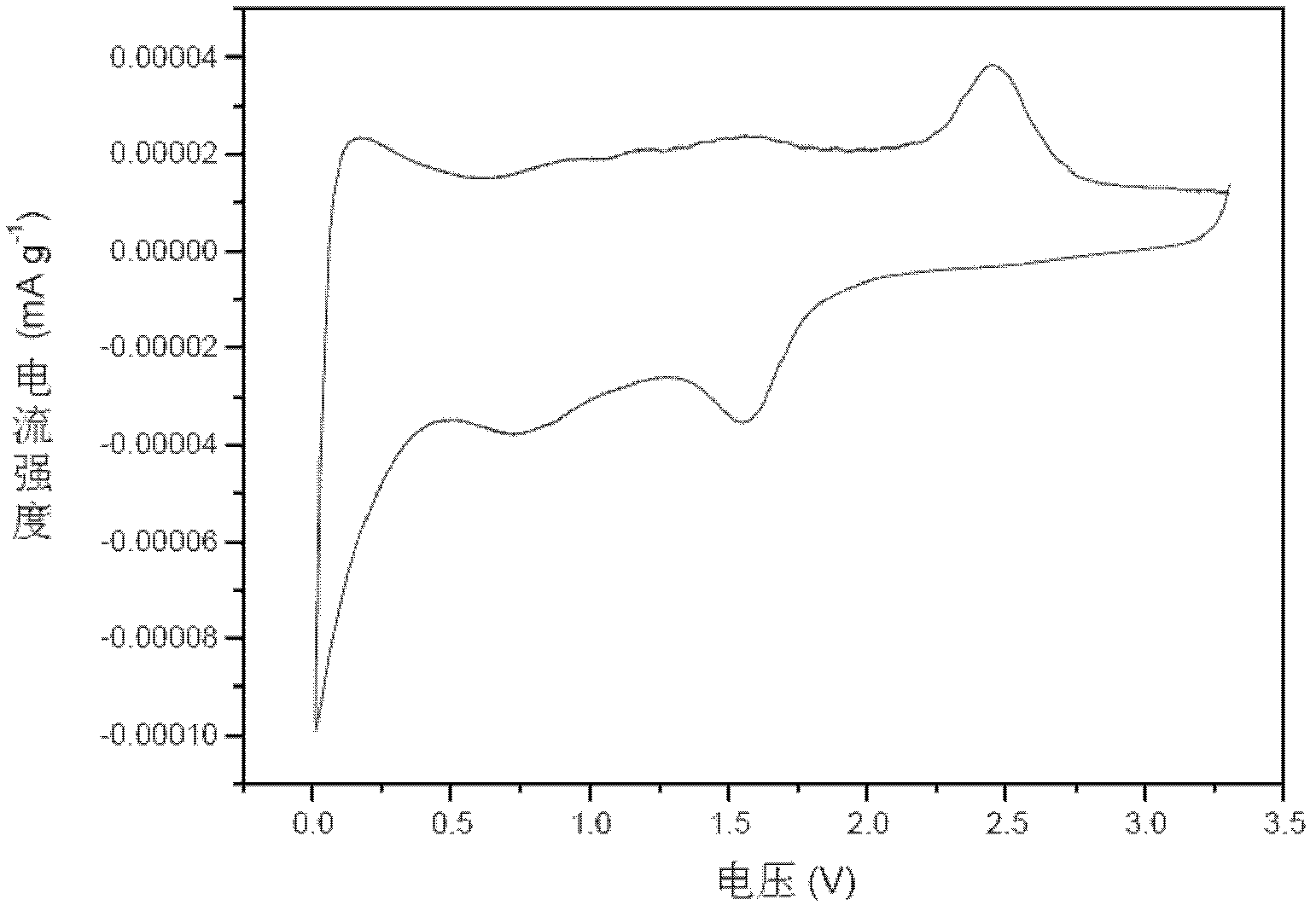

[0024] The resulting Cu 2 SEM images of O / Cu / PPy nanowires, such as figure 1 Shown; Cu 2 XRD diffraction patterns of O / Cu / PPy nanowires, such as figure 2 Shown; Cu 2 Cyclic voltammetry test of O / Cu / PPy nanowires packed into button batteries, such as image 3 Shown; Cu 2 O / Cu / PPy nanowires loaded into a button battery and charged and d...

Embodiment 2

[0026] Prepare a 0.2 mol / L pyrrole monomer solution and a 0.05 mol / L copper acetate solution, and disperse them evenly by ultrasonication. Take 16.25mL of the prepared pyrrole monomer solution and mix it with 65mL of the prepared copper acetate solution, and transfer it to a hydrothermal reaction kettle; place the hydrothermal reaction kettle in an oven, set the temperature to 140°C, and react for 15 hours; The product obtained by the reaction was centrifuged and washed, and dried at 50 ° C for 12 h, and the obtained Cu 2 O / Cu / PPy nanowires were assembled into a button lithium-ion battery, and the electrical properties were analyzed and characterized.

Embodiment 3

[0028] Prepare a 0.2 mol / L pyrrole monomer solution and a 0.05 mol / L copper acetate solution, and disperse them evenly by ultrasonication.

[0029] Take 13.5mL of the prepared pyrrole monomer solution and mix it with 65mL of the prepared copper acetate solution, and transfer it to a hydrothermal reaction kettle; place the hydrothermal reaction kettle in an oven, set the temperature to 130°C, and react for 20h; The product obtained by the reaction was centrifuged and washed, and dried at 50 ° C for 12 h, and the obtained Cu 2 O / Cu / PPy nanowires were assembled into a button lithium-ion battery, and the electrical properties were analyzed and characterized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com