Lithium-ion battery graphene composite ternary anode material and preparation method thereof

A graphene composite, lithium-ion battery technology, applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as poor rate performance, low conductivity and capacity decay, and achieve improved cycle performance and rate performance. Good rate performance, the effect of reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

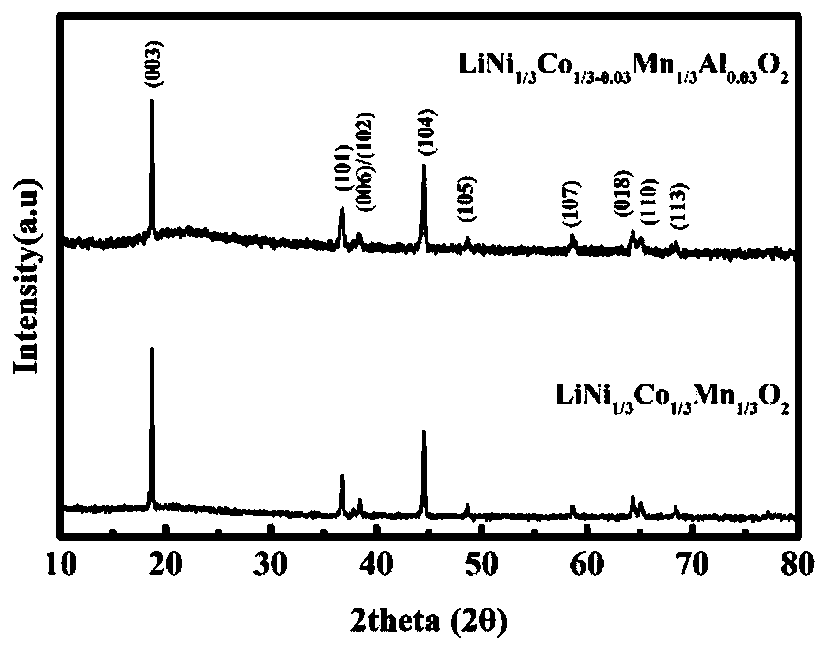

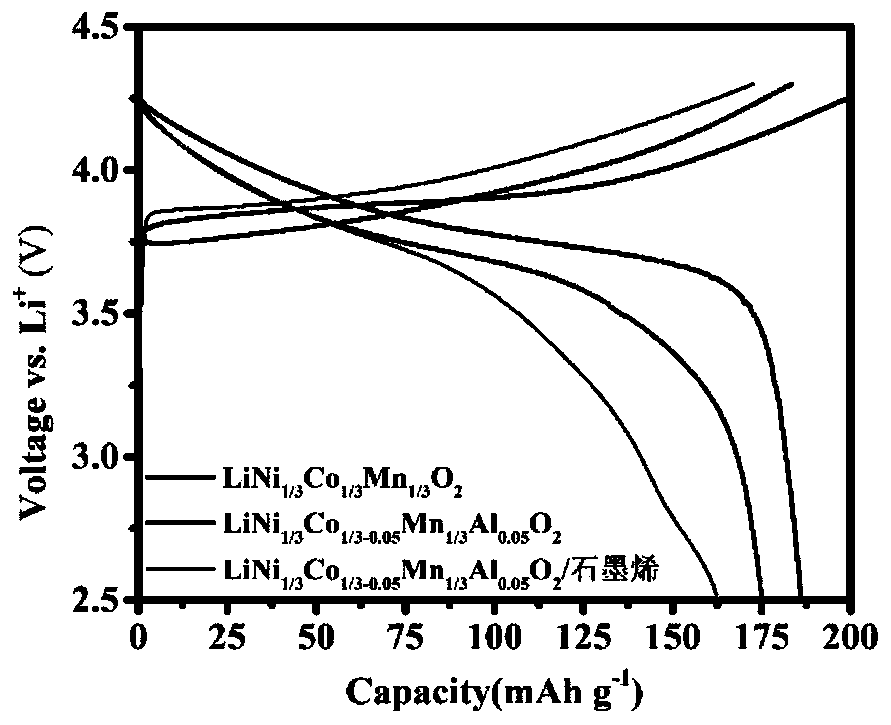

Embodiment 1

[0032] The preparation method of nickel-cobalt-manganese-lithium cathode material for lithium ion battery in this embodiment comprises the following steps:

[0033] (1) Weigh 0.79g of potassium permanganate and dissolve it in 50ml of deionized water, stir for 15 minutes to dissolve completely, then add 2ml of 37% hydrochloric acid dropwise to it, continue stirring for 15 minutes, then transfer to the reaction kettle, React at 140°C for 12 hours, centrifuge, wash, and dry at 70°C for 12 hours, transfer the resulting product to a crucible, and calcinate in a muffle furnace at 350°C for 6 hours to obtain the desired MnO 2 ;

[0034] (2) Weigh 0.5481g of lithium nitrate, 0.2174g of manganese dioxide, 0.7276g of cobalt nitrate nonahydrate, and 0.7270g of nickel nitrate nonahydrate and dissolve them in a mixed solution of 50ml of water and 50ml of ethanol, in order to compensate for the loss of lithium source during the calcination process , 6% excess lithium nitrate; ultrasonic fo...

Embodiment 2

[0037] In this embodiment, the preparation method of aluminum-doped nickel-cobalt-manganese-manganese-lithium positive electrode material for lithium ion battery comprises the following steps:

[0038] (1) Weigh 0.79g of potassium permanganate and dissolve it in 50ml of deionized water, stir for 15 minutes to dissolve completely, then add 2ml of 37% hydrochloric acid dropwise to it, continue stirring for 15 minutes, then transfer to the reaction kettle, React at 140°C for 12 hours, centrifuge, wash, and dry at 70°C for 12 hours, transfer the resulting product to a crucible, and calcinate in a muffle furnace at 350°C for 6 hours to obtain the desired MnO 2 ;

[0039] (2) Weigh 0.5481g lithium nitrate, 0.2174g manganese dioxide, 0.6620g cobalt nitrate nonahydrate, 0.7270g nickel nitrate nonahydrate, 0.0844g aluminum nitrate nonahydrate and dissolve them in a mixed solution of 50ml water and 50ml ethanol. Lithium source loss during calcination, lithium nitrate excess 6%; ultraso...

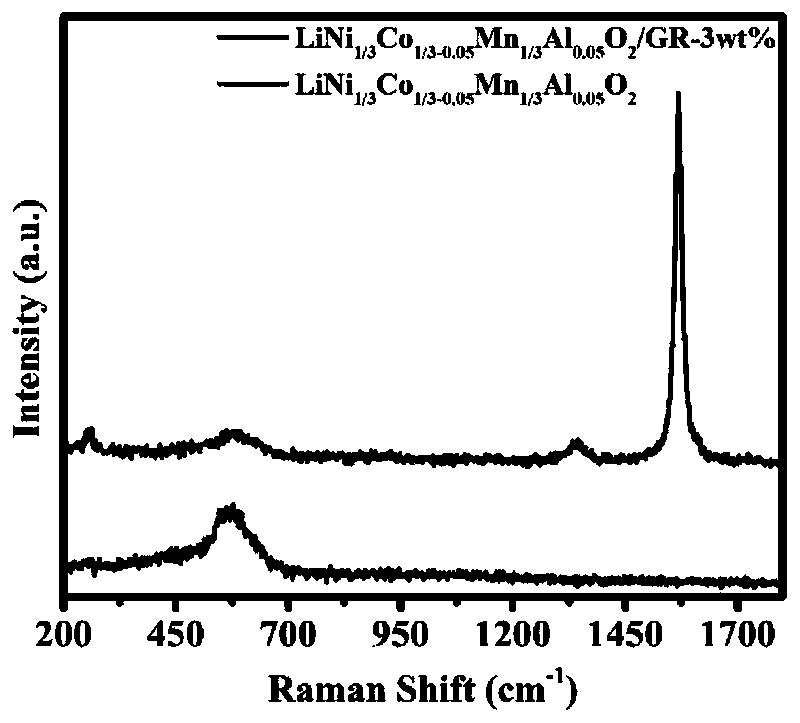

Embodiment 3

[0043] In this embodiment, the preparation method of aluminum-doped nickel-cobalt-manganese-manganese-lithium positive electrode material for lithium ion battery comprises the following steps:

[0044] (1) Weigh 0.79g of potassium permanganate and dissolve it in 50ml of deionized water, stir for 15 minutes to dissolve completely, then add 2ml of 37% hydrochloric acid dropwise to it, continue stirring for 15 minutes, then transfer to the reaction kettle, React at 140°C for 12 hours, centrifuge, wash, and dry at 70°C for 12 hours, transfer the resulting product to a crucible, and calcinate in a muffle furnace at 350°C for 6 hours to obtain the desired MnO 2 ;

[0045] (2) Weigh 0.5481g of lithium nitrate, 0.2174g of manganese dioxide, 0.6183g of cobalt nitrate nonahydrate, 0.7270g of nickel nitrate nonahydrate, and 0.1406g of aluminum nitrate nonahydrate and dissolve them in a mixed solution of 50ml of water and 50ml of ethanol. Lithium source loss during calcination, lithium n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com