High-energy-density multi-element positive electrode material and preparation method thereof

A technology of high energy density, positive electrode material, applied in the field of high energy density multi-element positive electrode material and preparation, can solve the problems of high cost of organic Zr source, inability to be applied on a large scale, low yield of hydrothermal method, etc. The effect of reducing residual inactive lithium content and interfacial resistance and increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Step 1 and Step 2 are consistent with the preparation steps of Comparative Example 1.

[0051] Step three, ZrO 2 , lithium hydroxide and the positive electrode material matrix obtained in step 2 are put into a high-speed mixer at the same time according to the material ratio of 0.5:3.8:100, mixed at a speed of 1200rpm for 10min, and then put into a muffle furnace for heat treatment. Heating at 600°C for 8 hours in an air atmosphere to obtain the average particle size D 50 10μm, the main component of the cladding layer is Li 8 ZrO 6 nickel-cobalt-manganese multicomponent material.

[0052] Such as figure 2 As shown, fine coating particles are evenly attached to the surface of the secondary particles of the positive electrode material prepared in this example, forming a non-dense coating layer.

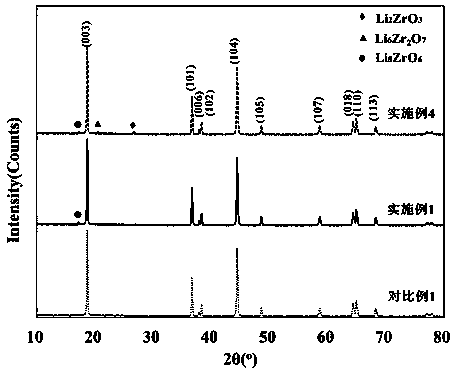

[0053] Such as image 3 As shown, in addition to the characteristic peaks of the main phase of the multi-element material, there are also Li 8 ZrO 6 The characteristic p...

Embodiment 2

[0059] Step 1. Dissolve nickel sulfate, cobalt sulfate, and manganese sulfate according to the metal molar ratio of 2:1:1 to obtain a 1.5mol / L mixed salt solution, and mix aluminum sulfate and sodium hydroxide according to a molar ratio of 1:10 to obtain Aluminum solution with an aluminum ion concentration of 0.2mol / L; Dissolve sodium hydroxide into an alkali solution with a concentration of 5mol / L; Dissolve ammonia water into a complexing agent solution with a concentration of 2mol / L. Add the mixed salt solution, aluminum solution, alkali solution, and complexing agent solution together into the reactor for reaction. During the process, keep the stirring speed at 115rpm constant, control the pH to 11.8-12.0, and the temperature to 55°C. When the reaction is completed, keep Keep the temperature and stirring speed constant, continue to stir for 20 minutes, then separate the solid and liquid from the prepared nickel-cobalt-manganese-aluminum hydroxide slurry, wash it, dry the fil...

Embodiment 3

[0064] Step 1, dissolving nickel sulfate, cobalt sulfate, and manganese sulfate according to the ratio of metal molar ratio 8:1:1 to obtain a mixed salt solution of 2.5mol / L, dissolving sodium hydroxide into an alkali solution with a concentration of 6mol / L, and dissolving Ammonia solution was dissolved into a complexing agent solution with a concentration of 6mol / L. Add the mixed salt solution, alkali solution, and complexing agent solution together into the reactor for reaction. During the process, keep the stirring speed at 125rpm constant, control the pH to 11.9-12.1, and the temperature to 65°C. When the reaction is completed, keep the temperature and stir Keep the rotation speed constant, and continue to stir for 20 minutes. Then, the prepared nickel-cobalt-manganese hydroxide slurry is subjected to solid-liquid separation and washing. The filter cake is dried at 120° C. for 4 hours and then sieved to obtain spherical nickel-cobalt-manganese hydroxide material.

[0065] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com