Silver conductive coating material of lithium ion battery, preparation method of silver conductive coating material and lithium ion battery

A lithium-ion battery, conductive coating technology, applied in conductive materials dispersed in non-conductive inorganic materials, battery electrodes, cable/conductor manufacturing, etc. problems, to achieve the effect of improving production efficiency, low internal resistance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the conductive coating material of the above-mentioned lithium ion battery comprises the following steps: according to the proportion of each component in the above-mentioned conductive coating material, the conductive agent and the polyvinylpyrrolidone are sequentially added to the aqueous dispersion of the acrylonitrile multipolymer, and the mixture is stirred. Afterwards, grinding and dispersing are carried out for several times until the dispersion is uniform, so as to obtain the conductive coating material for the lithium ion battery.

[0027] In a preferred case, the preparation method further includes adding a chelating agent to the binder, stirring and chelating, dispersing in water, and then adding the conductive agent and polyvinylpyrrolidone in sequence according to the proportion of each component in the conductive coating material , further adding a defoaming agent and a preservative, after stirring, grinding and dispersing for seve...

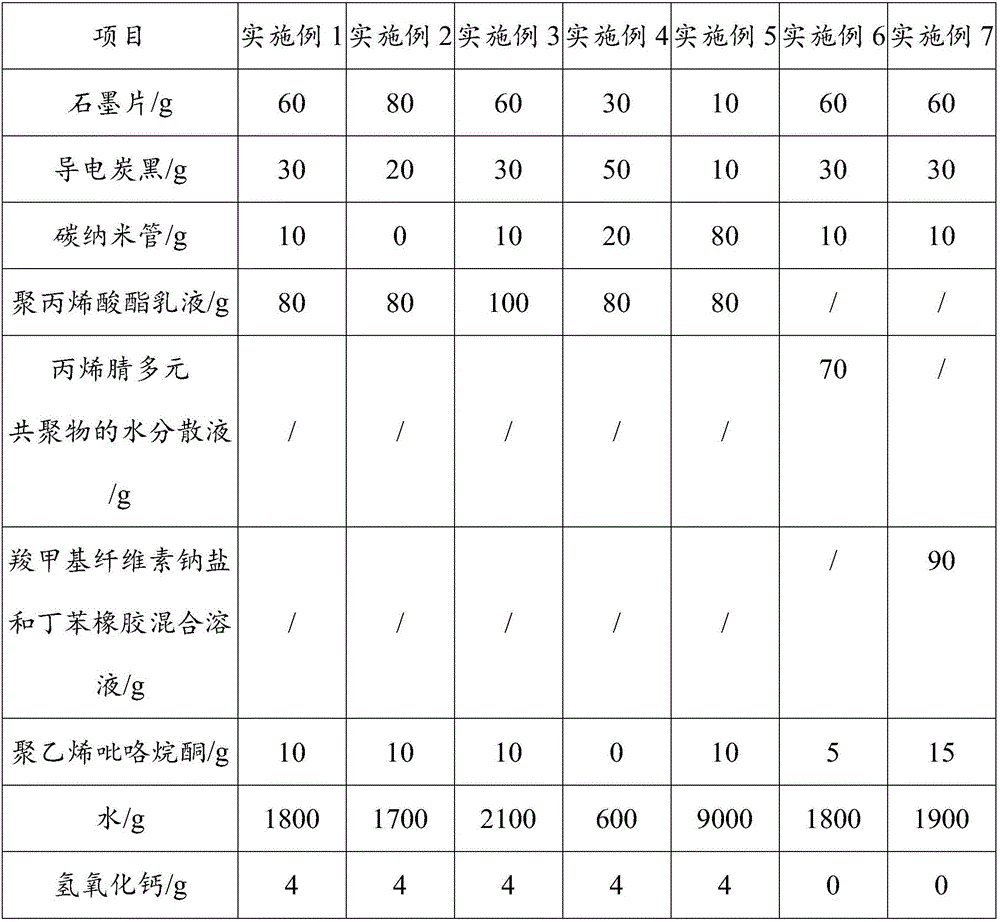

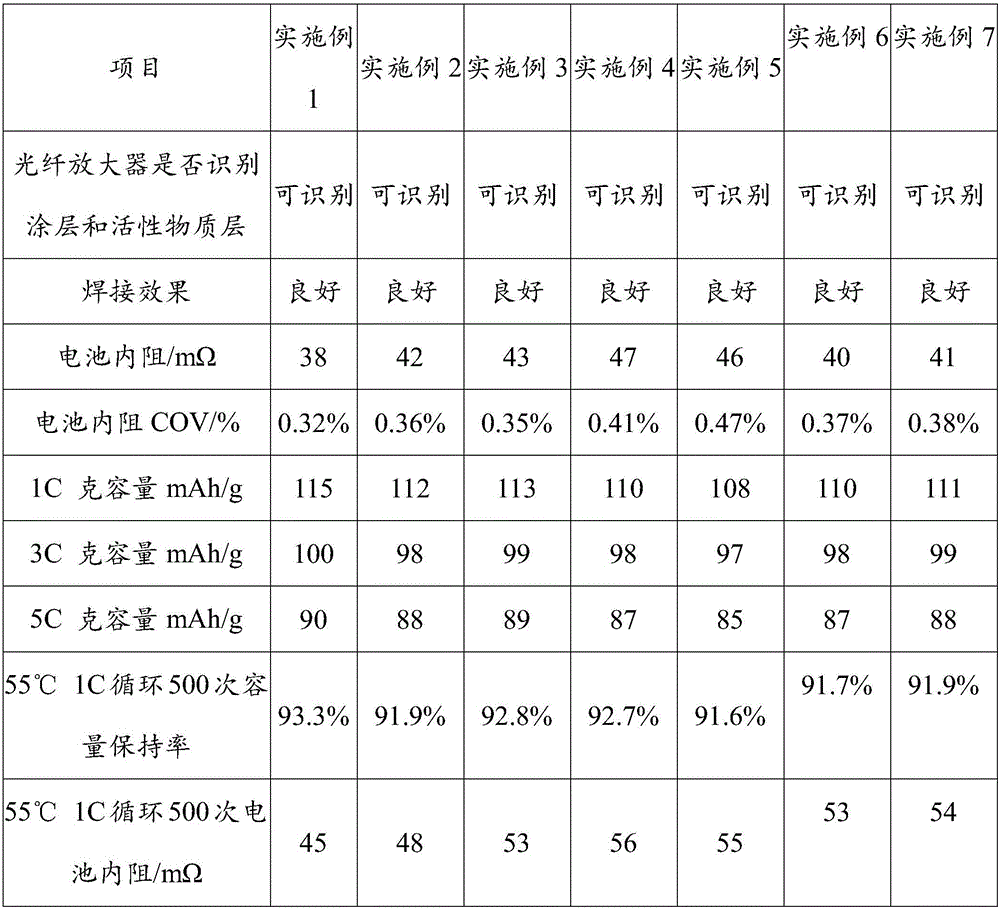

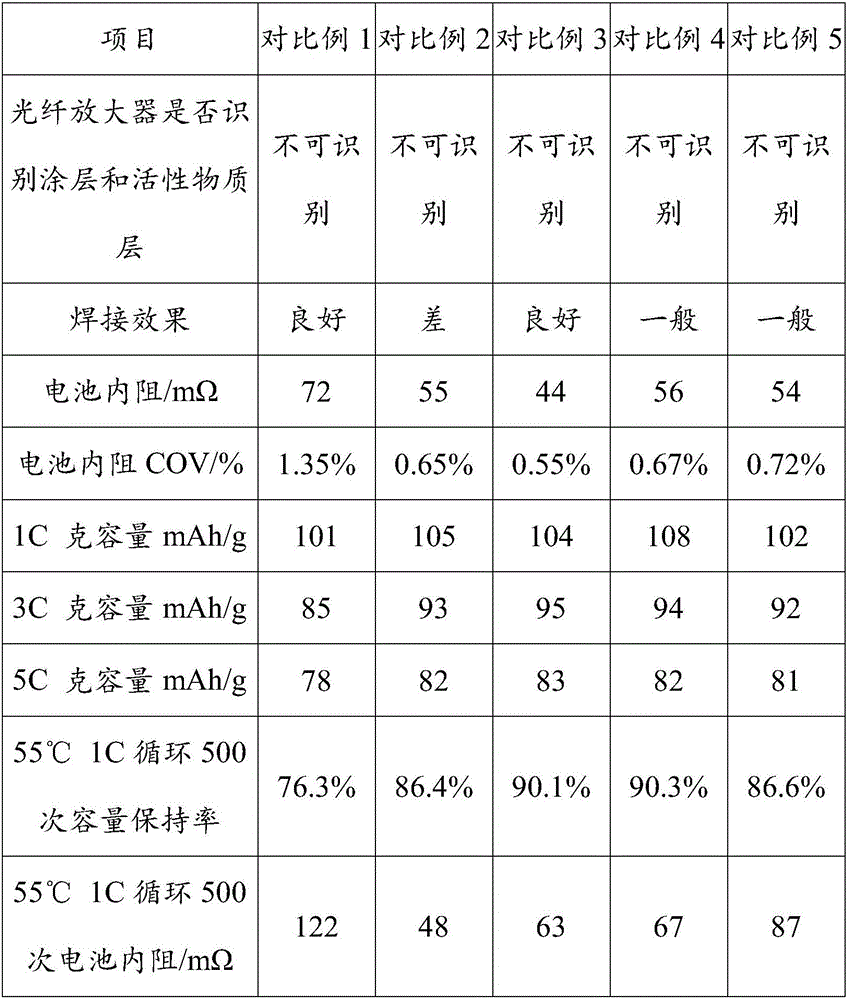

Embodiment 1~7

[0033] (1) Add calcium hydroxide to the binder shown in Table 1 according to the composition and content of the conductive coating material in Table 1, stir and disperse in water after chelating for 24 hours, and then press the conductive coating material in Table 1. Component and content of layer material The conductive agent and polyvinylpyrrolidone are added to the aqueous dispersion of the chelated binder in turn, and after stirring for 1 hour (wherein, the stirring linear speed is 20m / s), and then pass through a ball mill. Grinding was carried out for 5 times until the dispersion was uniform, and the silver conductive coating materials of the lithium ion batteries of Examples 1-5 were obtained.

[0034] (2) According to the existing lithium ion battery manufacturing method, a lithium ion battery is manufactured, the difference is that a layer of silver conductive coating material is first coated on the positive electrode sheet and the negative electrode sheet current colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com