Multiphase material level sensor

A material level sensor and transmitter technology, applied in containers, liquid level indicators for physical variable measurement, large containers, etc., can solve problems such as inability to measure multi-phase material levels, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

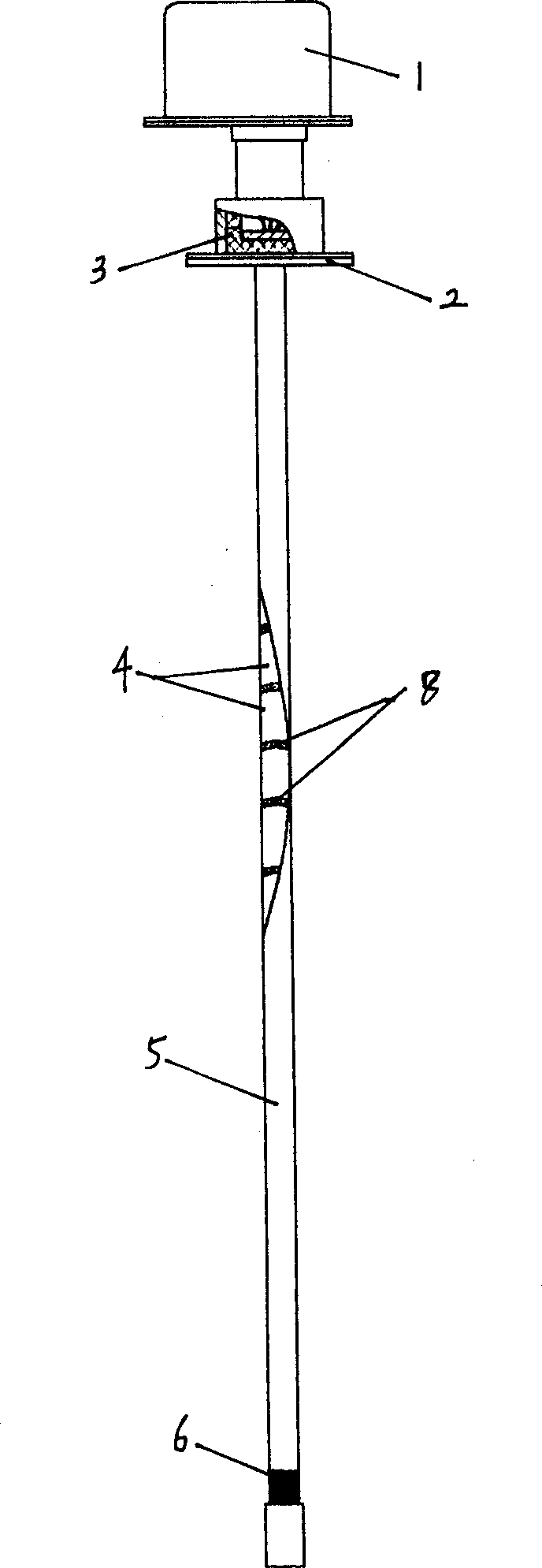

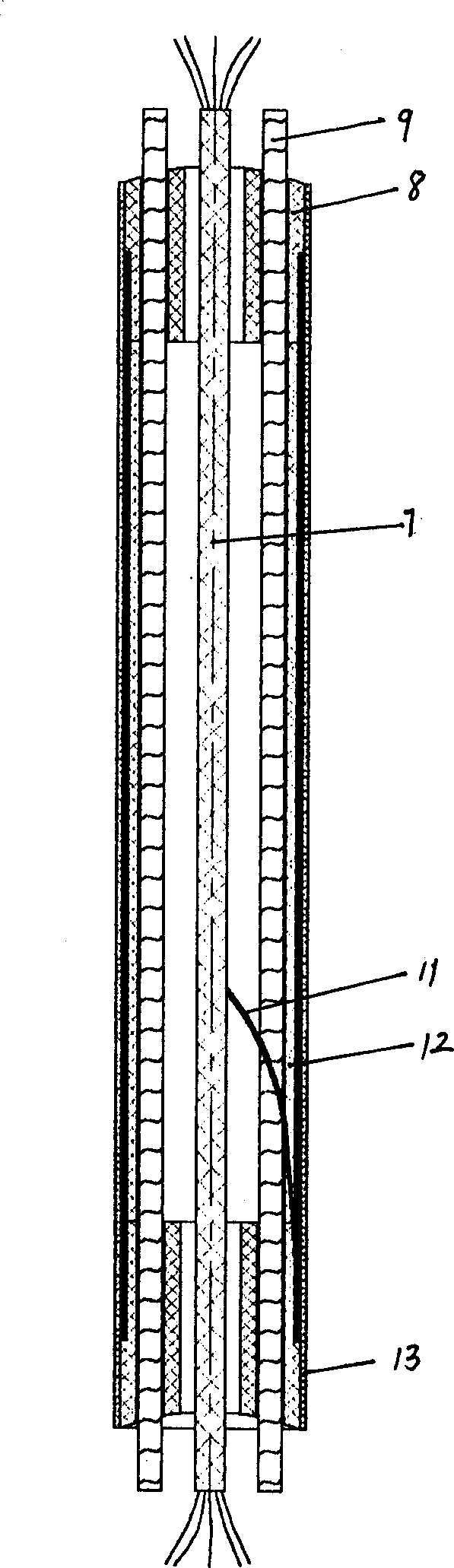

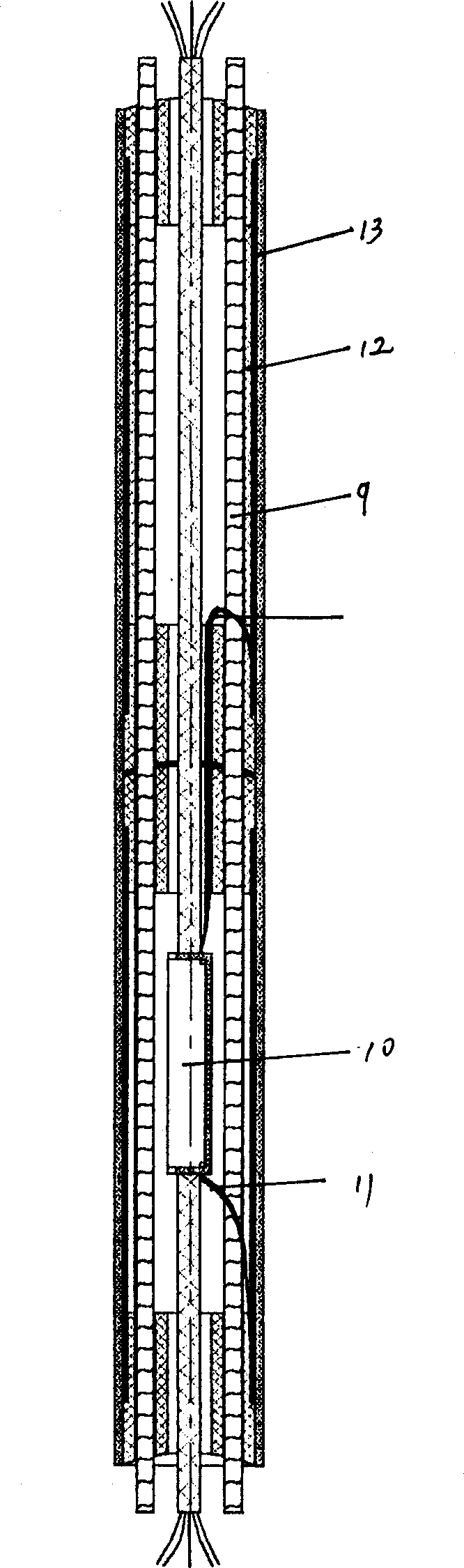

[0014] exist figure 1 , figure 2 , image 3 Among them, the metal main pole of the present invention is connected in series by multiple tubular metal poles (4) on the connecting body (9) wrapped with an inner insulating sleeve (12) on the outside, and the main purpose of the inner insulating sleeve (12) is to separate each branch The pole (4) is isolated from the connecting body (9) and other conductive parts, an insulating layer (8) is provided between two adjacent sub-poles (4), and the inner cavity of the connecting body (9) is provided with a cable ( 7), an outer insulating sleeve (13) is arranged around the outer side of the main pole. The main function of the outer insulating sleeve (13) is to isolate each pole (4) and the entire sensor from the conductive medium (such as water) on the side, and the metal The upper end and the lower end of the main pole are respectively provided with an upper insulator (3) and a lower insulator (6). The transmitter (1) and the flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com