Integral high-speed permanent-magnet brushless direct-current motor for electric tool

A permanent magnet brushless DC and electric tool technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of troublesome assembly, high process requirements, and high price, and achieve stable operation, simple process, and convenient assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

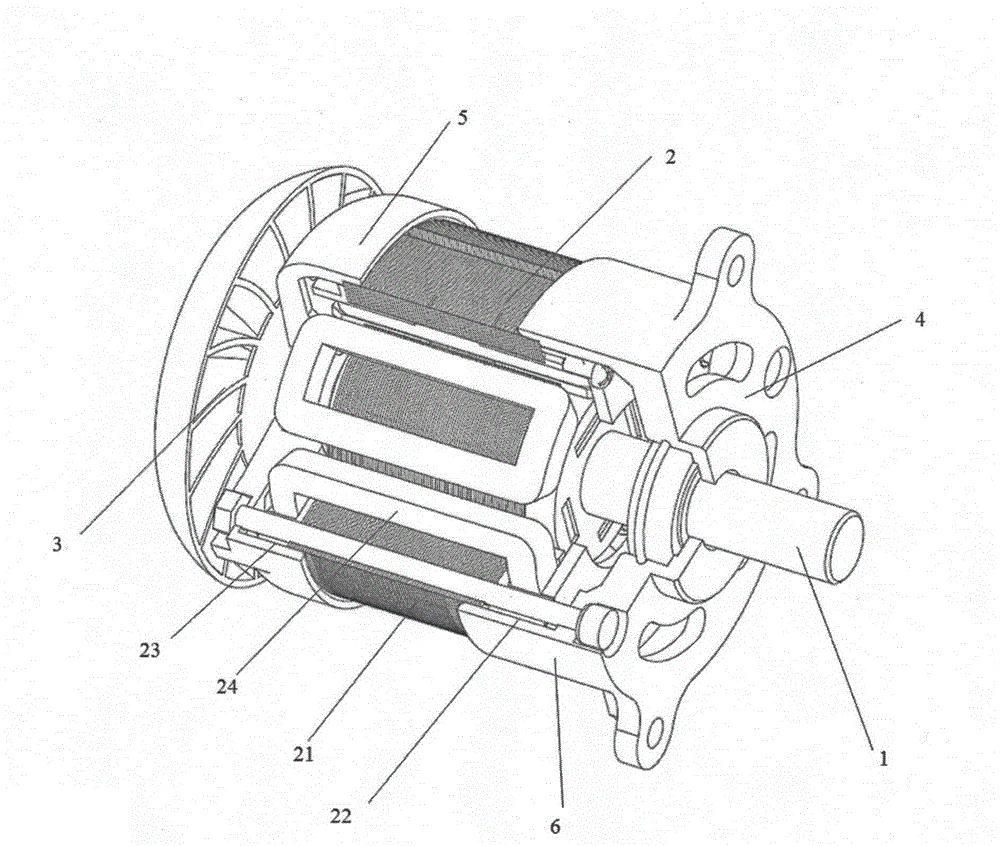

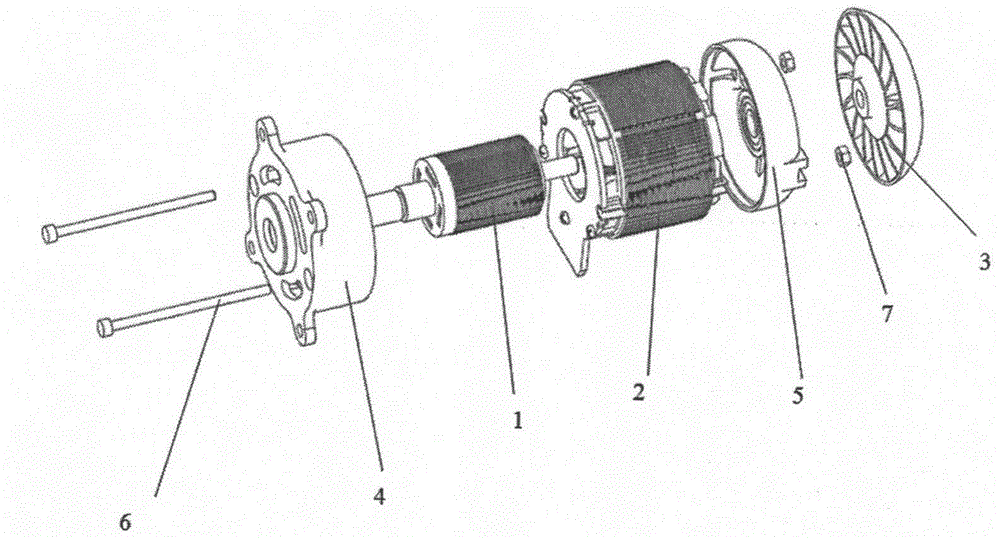

[0025] The installation size of a high-speed integrated permanent magnet brushless DC motor used in electric tools provided by the present invention is exactly the same as that of a standardized integral permanent magnet brushed DC motor. On the basis of tool products, it can be applied to the needs of different customers, including the rotor 1 and the stator 2 sleeved outside the rotor 1. It is characterized in that the front end cover 4 and the rear The end cover 5 and the screw rod 6 pass through the front end cover 4 and the rear end cover 5 and cooperate with the nut 7 to assemble the rotor 1, the stator 2, the front end cover 4 and the rear end cover 5 into a whole, and the fan blade 3 is located at the rear end cover 5 or the front end cover 4, the blades 3 are connected to the rotor 1 to rotate with the rotor 1.

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com