Photosensitive resin composition containing polyimide resin and novolak resin

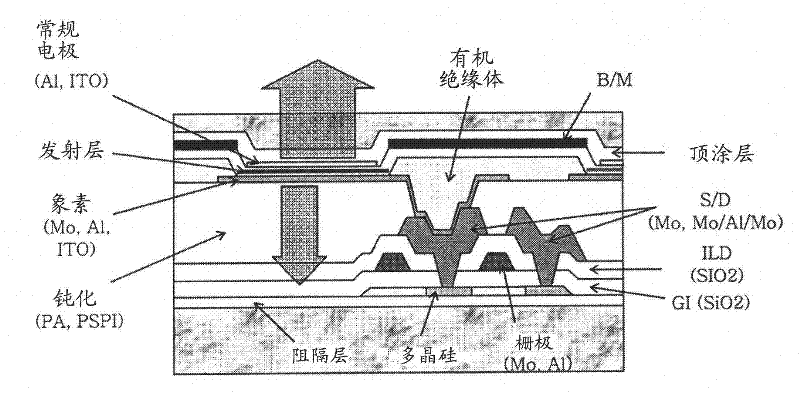

A technology of polyimide resin and novolak resin, applied in the field of photosensitive resin compositions, can solve the problems of poor heat resistance of novolak resin, difficulty in developing patterns, etc., and achieves easy control, easy pattern lateral angle, The effect of precise critical dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0071] Hereinafter, the present invention will be described in more detail with reference to the following examples. However, these examples are for illustrative purposes only and do not limit the present invention. In the following examples, all parts and percentages are by weight unless otherwise stated.

Embodiment 1

[0074] m-cresol and p-cresol were mixed in a weight ratio of 5:5 to prepare a novolak resin having a weight average molecular weight based on polystyrene of 4,500. A photosensitizer was prepared by reacting 1 mole of 2,3,4,4'-tetrahydroxybenzophenone with 3 moles of 1,2-diazidonaphthoquinone-5-sulfonyl chloride. 133 g (0.30 mol) of 4,4'-hexafluoroisopropylidene diphthalic anhydride as anhydride with 87 g (0.31 mol) of bis(3-amino-4-hydroxyphenyl) sulfone as diamine and 16 g (0.07 mol) 1,3-bis(3-aminopropyl)tetramethyldisiloxane was reacted at 180° C. for 1 hour to prepare a soluble polyimide resin of formula 2:

[0075]

[0076] 4.5 g of novolac resin, 4 g of photosensitizer and 13.5 g of soluble polyimide resin were dissolved in γ-butyrolactone and ethyl lactate. This solution was filtered through a 0.2 μm membrane to prepare a resin composition.

Embodiment 2

[0078] A photosensitive resin composition was prepared in the same manner as in Example 1 except that 9 g of novolak resin and 9 g of polyimide resin were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com