Three axis optical fibre gyroscope inertia measurement unit integral structure

An inertial measurement unit and fiber optic gyroscope technology, which is applied to Sagnac effect gyroscopes and other directions, can solve the problem of large deviation between the inertial measurement unit mass center and the geometric installation center, affecting the temperature field distribution of the inertial measurement unit, and temperature compensation of unfavorable components. Control and other issues, to achieve the effect of being conducive to heat dissipation, temperature compensation and control, and small processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

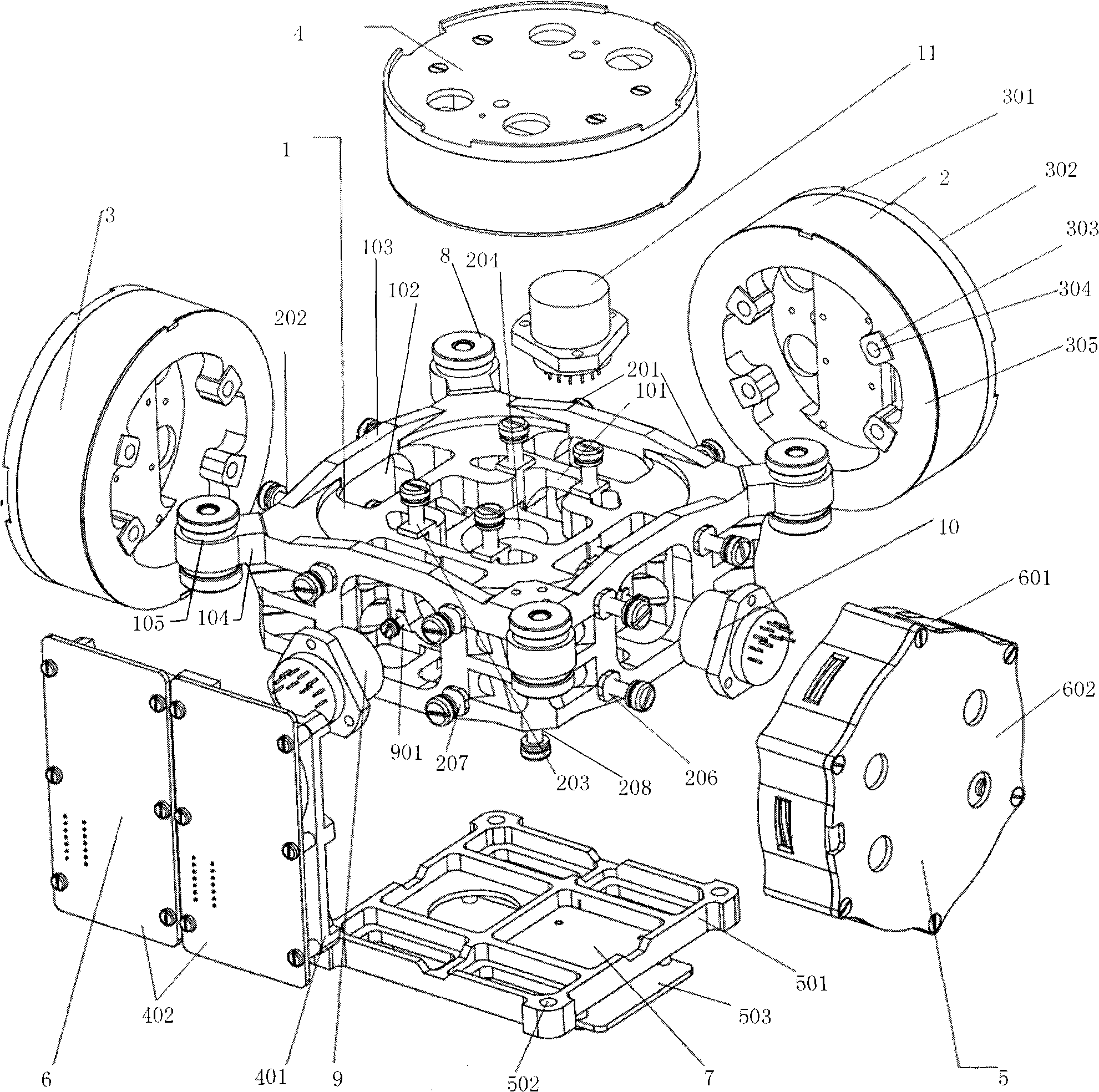

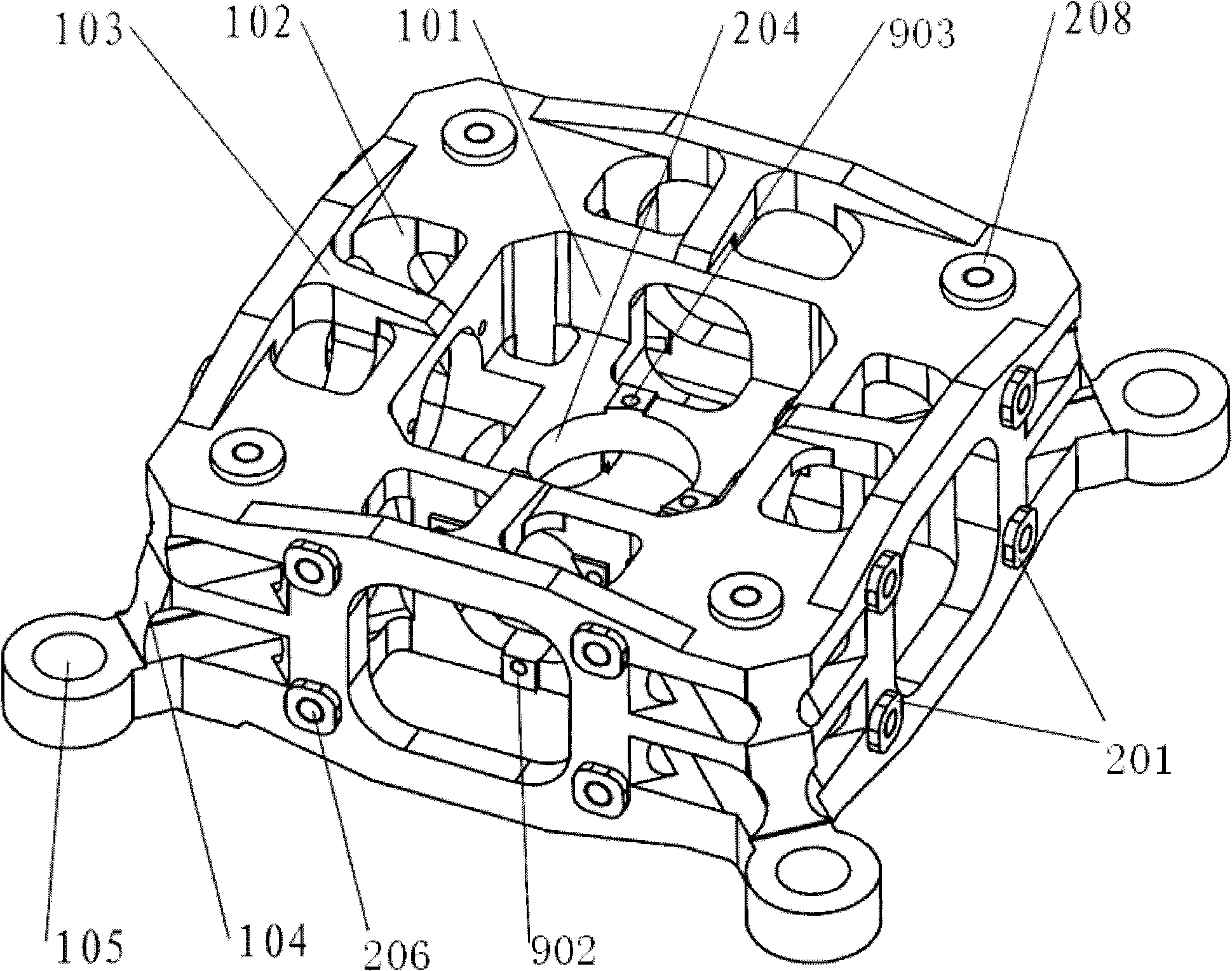

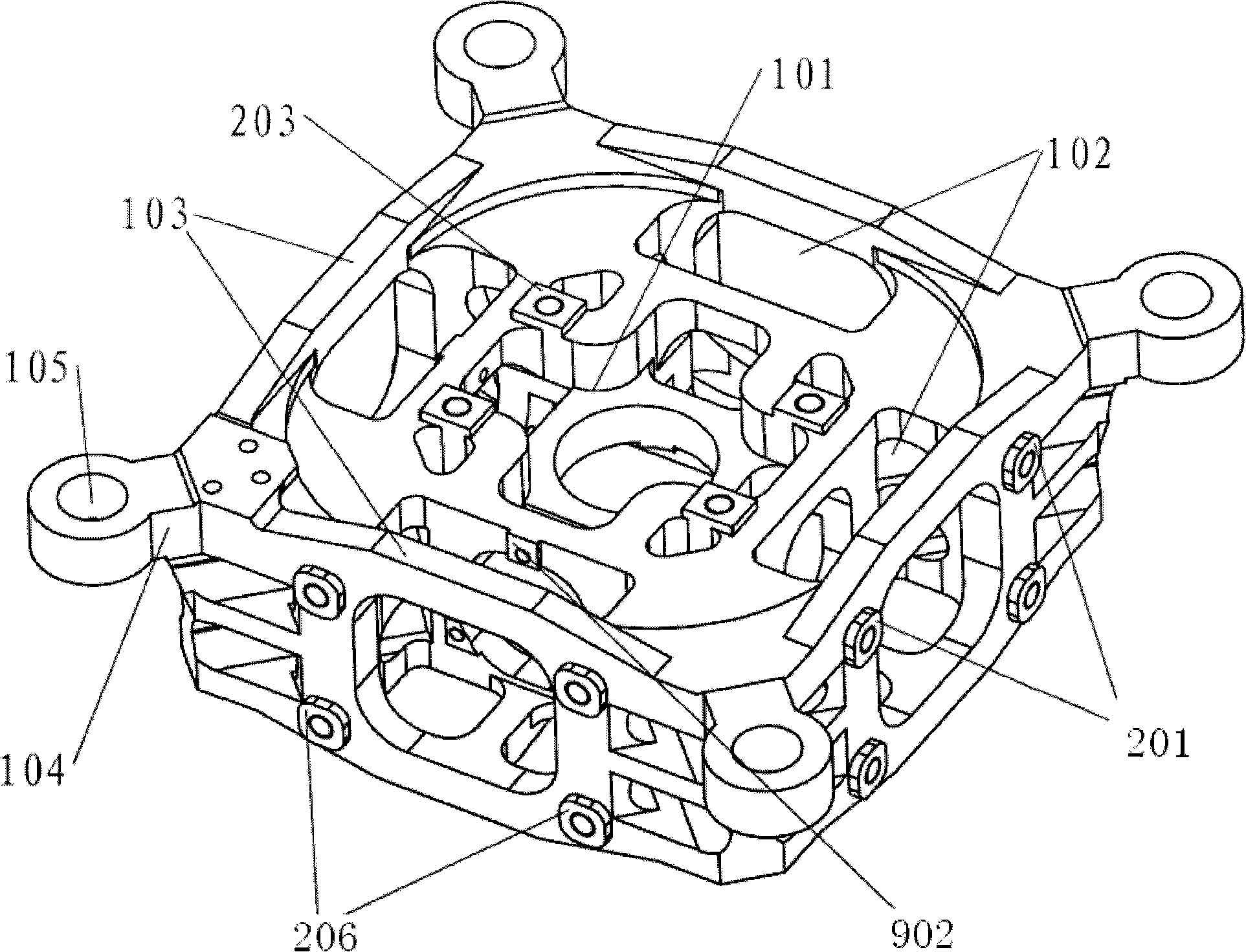

[0044] Such as figure 1 , Figure 7 , Figure 8 As shown, an integrated structure of a three-axis fiber optic gyro inertial measurement unit includes a mounting frame 1, and three fiber optic gyroscopes, three accelerometers, a light source, and a circuit board installed on it through multiple sets of mounting holes on the mounting frame 1 , Shock absorber 8.

[0045] The mounting frame 1 adopts a hollow hexahedron frame structure, and each group of mounting holes is symmetrically arranged, and mounting bosses are provided on the positioning end faces of the mounting holes. The installation frame 1 adopts a hollow hexahedron frame structure, which not only ensures the overall rigidity and strength, but also makes the mass of the installation frame 1 very small. The symmetrical arrangement of each group of mounting holes is beneficial to minimize the deviation between the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com