Micro attitude and heading reference system based on 3D stereoscopic packaging technology

A three-dimensional, reference system technology, applied in the field of inertial sensing systems, can solve the problems of large installation errors, high precision, and high processing costs, and achieve the effects of improving structural reliability, reducing non-orthogonal errors, and reducing installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

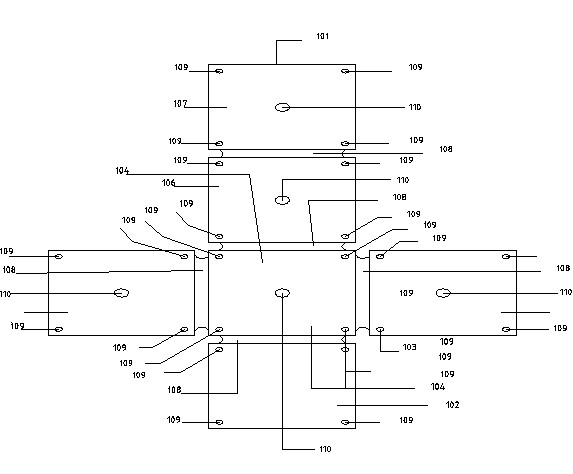

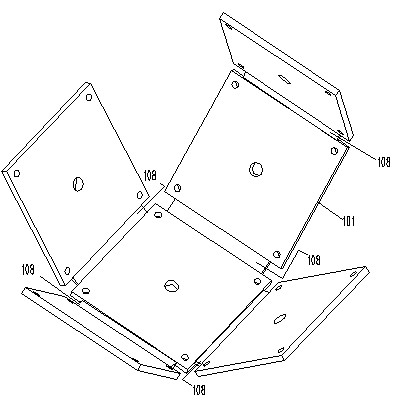

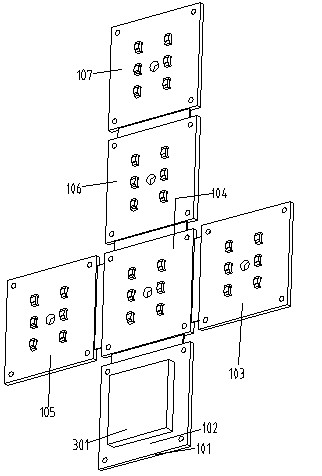

[0039] like Figure 1 to Figure 8 As shown, the reference numbers are as follows: multilayer rigid-flexible board 101, first rigid printed circuit board part 102, second rigid printed circuit board part 103, third rigid printed circuit board part 104, fourth rigid printed circuit board part 105, fifth rigid printed circuit board part 106, sixth rigid printed circuit board part 107, ligament 108, positioning hole 109, circuit board mounting hole 110, passive element 201, microprocessor 301, three-dimensional space integrated base 401, left Plane 402, Front Plane 403, Lower Plane 404, Rear Plane 405, Right Plane 406, Upper Plane 407, Positioning Screw 409, Base Mounting Hole 410, Glue Pouring Groove 411, Main Device Groove 412, Zigzag-shaped Secondary Device Mounting Groove 413 , a single-axis gyroscope 701 , a three-axis accelerometer 702 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com