True triaxial multi-field multi-phase coupling dynamic test system and method

A technology of coupled dynamics and test system, applied in the field of true three-axis multi-field multi-phase coupled dynamics test system, can solve the problems of incomplete test measurement, large gap between sample tests, inability to provide data support for research, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

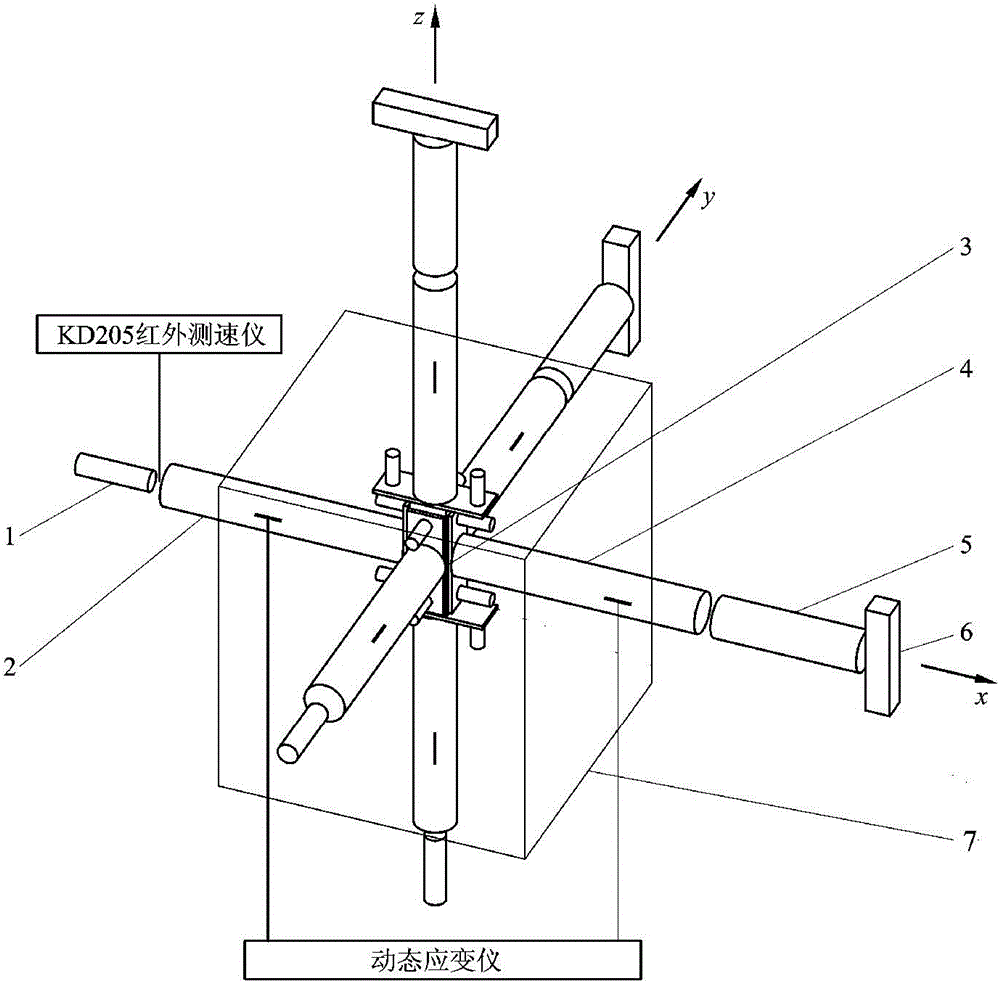

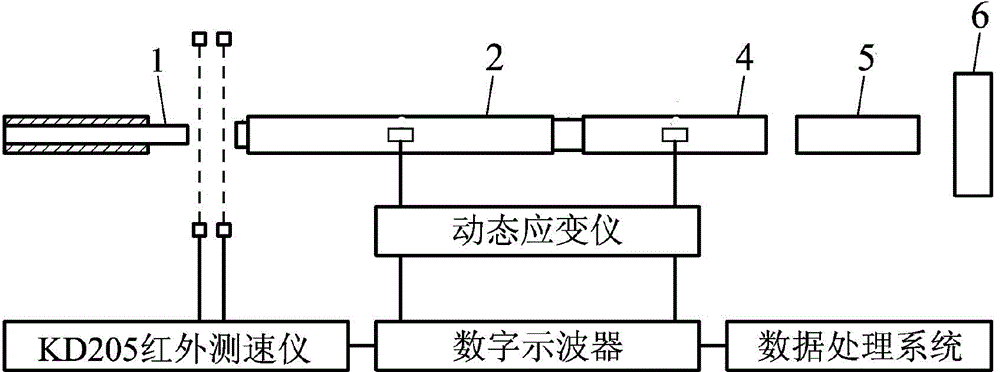

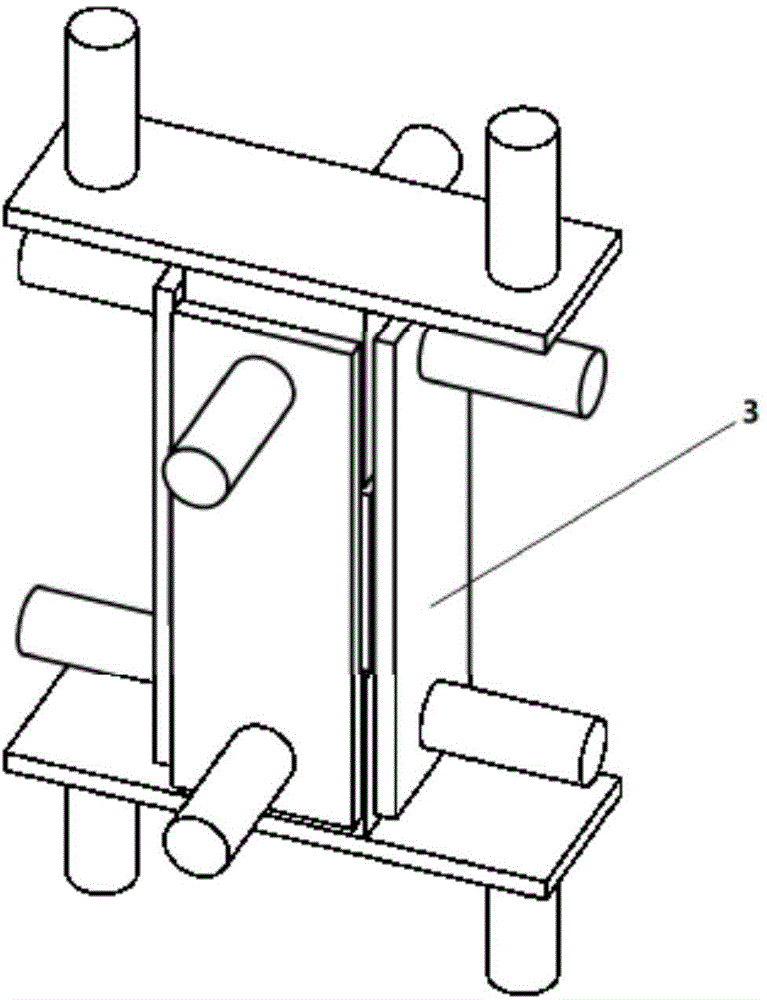

[0037] Such as Figure 1 to Figure 7 As shown, the present invention includes a test shaft, a hydraulic system, a bullet 1, an infrared velocimeter, a dynamic strain gauge, a digital oscilloscope and a data processing system, the bullet 1 and the test shaft are on the same axis, and the test shaft includes a three-axis loading device 3. The incident rod 2, the transmission rod 4, the absorption rod 5 and the absorber 6, one end of the incidence rod 2 and one end of the transmission rod 4 are respectively fixed to the two ends of the three-axis loading device 3; the other end of the transmission rod 4 is sequentially connected to the absorption The rod 5 and the absorber 6 are compressed and are on the same axis as the absorbing rod 5 and the absorber 6; the triaxial loading device 3 is a hexahedron, including three groups of pressure devices arranged oppositely; the six pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com