PCN (Porous Coordination Network) 222 metal organic framework material as well as preparation method and application thereof

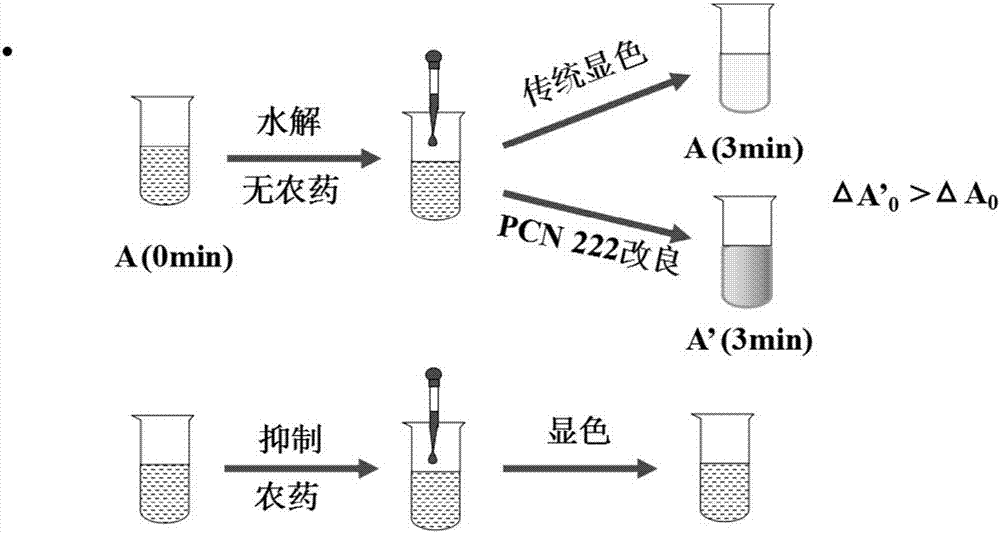

A metal-organic framework, PCN222 technology, applied in the direction of color/spectral characteristic measurement, etc., to achieve the effect of low cost, improved sensitivity, and high-efficiency enzyme inhibition method detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The implementation steps are as follows:

[0044] Step 1, take ZrCl 4 140mg, TCPP 100mg and benzoic acid 5500mg in a beaker, add DMF 16mL, ultrasonic 30min to make it uniform;

[0045] Step 2. Pour the uniformly mixed solution into the reaction kettle and react at 120°C for 48 hours;

[0046] Step 3. After the hydrothermal reaction is completed, the product is centrifuged to remove the upper liquid, and the ethanol is repeatedly centrifuged and washed 3 times: the rotation speed is 7000 rpm, and the rotation speed time is 5 minutes

[0047] Step 4, drying at a temperature of 100° C. for 12 hours to obtain a solid powder of brown PCN 222 metal-organic framework material (abbreviated as PCN 222 hereinafter).

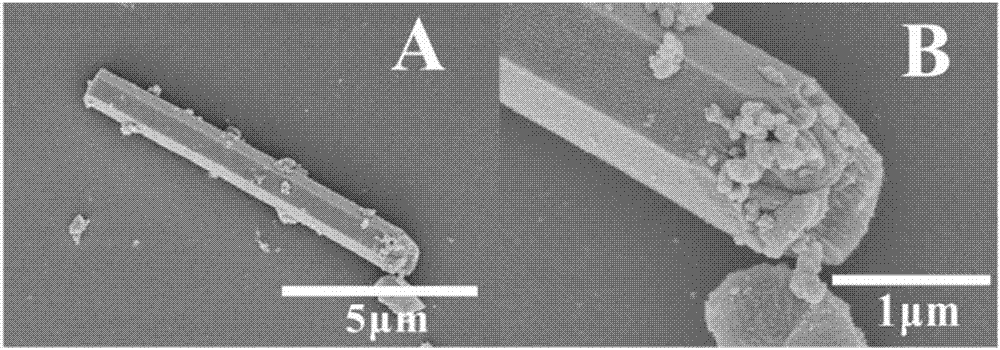

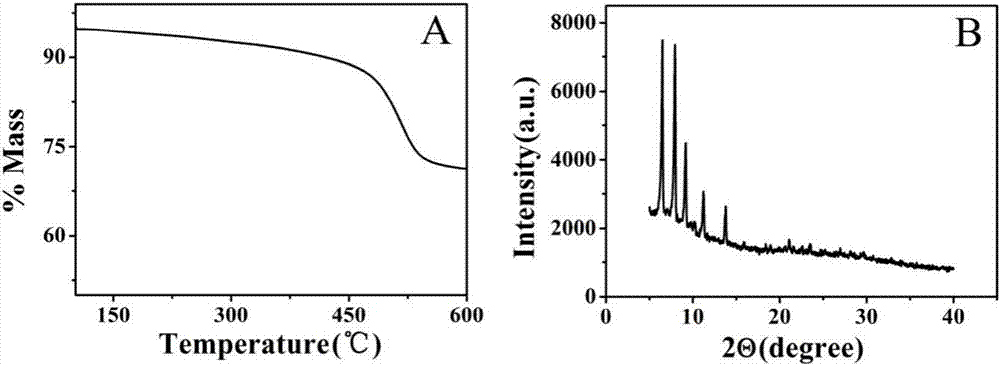

[0048] The characterization results of PCN 222 synthesized by the above experimental steps are as follows:

[0049] In order to study the microscopic morphology of the crystal growth of PCN 222, and to characterize whether the MOFs material was successfully prepar...

Embodiment 2

[0053] The implementation steps are as follows:

[0054] Step 1, take ZrCl 4 Put 120mg, TCPP 100mg and benzoic acid 5800mg in a beaker, add DMF 12mL, ultrasonic 30min to make it uniform;

[0055] Step 2. Pour the uniformly mixed solution into the reaction kettle and react at 130°C for 45h;

[0056] Step 3. After the hydrothermal reaction is completed, the product is centrifuged to remove the upper liquid, and the ethanol is repeatedly centrifuged and washed 3 times: the rotation speed is 6000 rpm, and the rotation speed time is 6 minutes

[0057] Step 4, drying at a temperature of 120° C. for 10 h to obtain a solid powder of brown PCN 222 metal-organic framework material (abbreviated as PCN 222 hereinafter).

Embodiment 3

[0059] The implementation steps are as follows:

[0060] Step 1, take ZrCl 4 160mg, TCPP 100mg and benzoic acid 5000mg in a beaker, add DMF 20mL, ultrasonic 30min to make it uniform;

[0061] Step 2. Pour the uniformly mixed solution into the reactor and react at 110°C for 51 hours;

[0062] Step 3. After the hydrothermal reaction is completed, the product is centrifuged to remove the upper liquid, and the ethanol is repeatedly centrifuged and washed 3 times: the rotation speed is 8000 rpm, and the rotation time is 3 minutes

[0063] Step 4, drying at 60° C. for 14 hours to obtain solid powder of brown PCN 222 metal-organic framework material (abbreviated as PCN 222 hereinafter).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com