Fan blade based on hollow metal/composite material structure

A technology of composite materials and fan blades, which is applied to components of pumping devices for elastic fluids, machines/engines, liquid fuel engines, etc., can solve the problems that metal wide-chord blades cannot meet strength and other design requirements, and achieve Structural shape and position can be designed strong, good casing tolerance, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

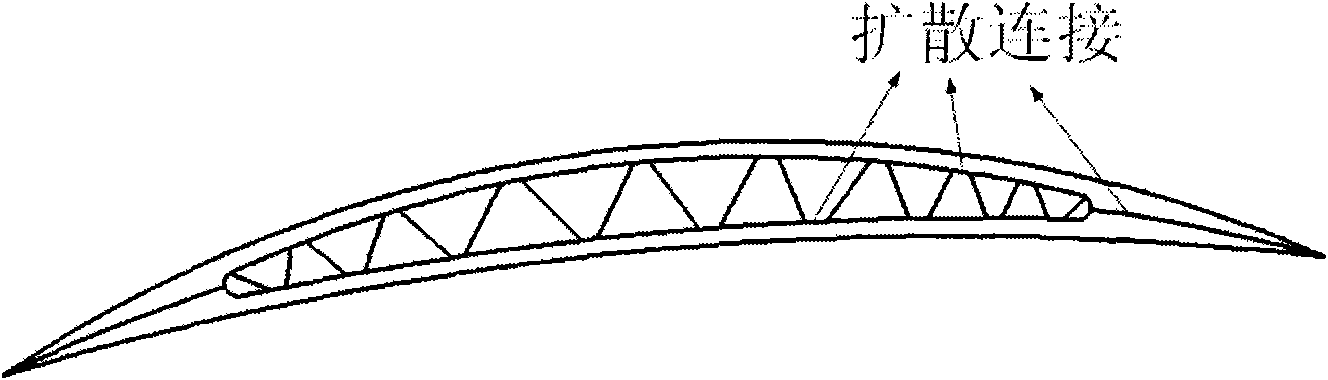

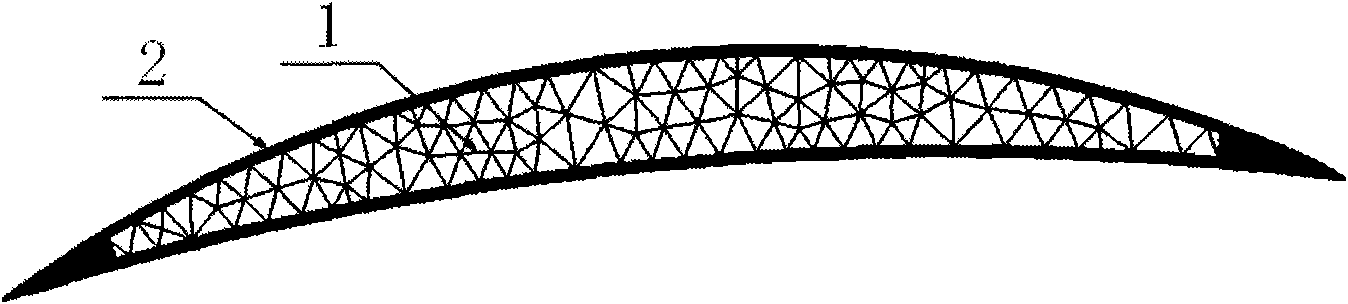

[0030] Such as Figure 4 The fan blade with wide chord and no shoulders is shown in the picture on the left. The shape of the blade has been aerodynamically designed to meet the overall performance requirements of the engine for fan components. The blades are discretized in space by using tetrahedral elements. The connection lines of the nodes of the tetrahedral elements are the ribs of the fan blades, and the node nodes of the elements are the connection points of the ribs. Figure 4 As shown on the right, Figure 5 It is a schematic diagram of the distribution of the rib structure 1 on the surface 2 of the fan blade. Fan blades are constructed from this hollow structural metal / composite framework, which is much less massive than solid metal blades.

[0031]Fan blades are subjected to centrifugal load during operation, and the centrifugal force gradually increases as the radius decreases, so the rib diameter must increase as the radius decreases to weaken the tensile stress...

Embodiment 2

[0036] A fan blade based on a hollow structure metal / composite material framework as in Embodiment 1, wherein the rib structure 1 is made of such as Figure 7 The diamond crystal structure shown is formed.

Embodiment 3

[0038] A fan blade based on a hollow structure metal / composite material framework as in Embodiment 1, wherein the rib structure 1 is made of such as Figure 8 The hexahedral unit structure shown is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com