Grating anchor rod force-measuring device and method for monitoring anchor rod stress variation

A fiber grating and force-measuring device technology, which is applied in the direction of measuring the force of the change in optical properties of the material when it is stressed, can solve the high requirements of sensors such as waterproof, moisture-proof, crack-proof, and anti-corrosion, and it is difficult to realize automatic data. Acquisition and processing, affecting the reliability and service life of the instrument and other issues, to achieve the effect of easy protection and maintenance, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Accompanying drawing is embodiment of the present invention.

[0025] Below in conjunction with accompanying drawing, content of the invention will be further described:

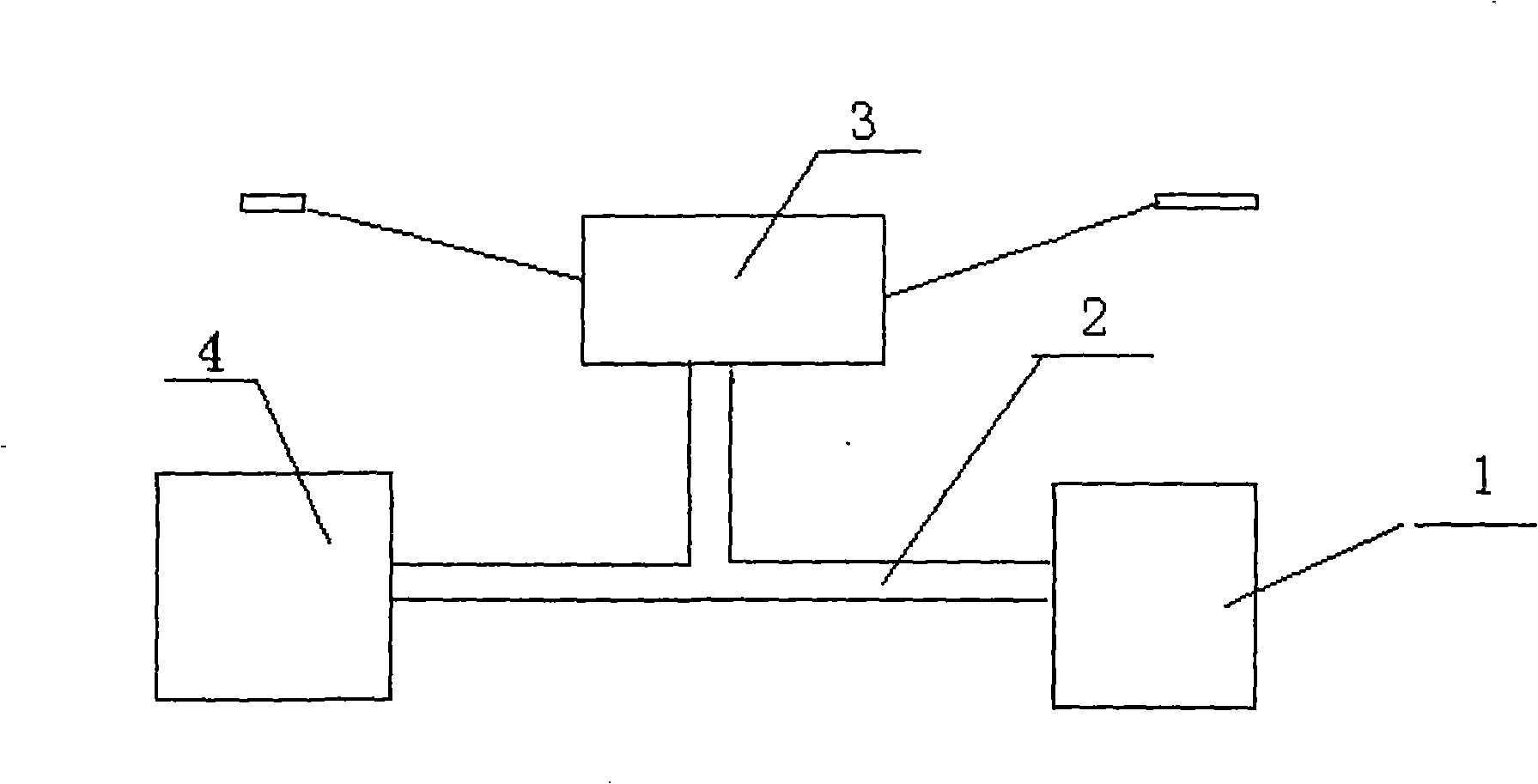

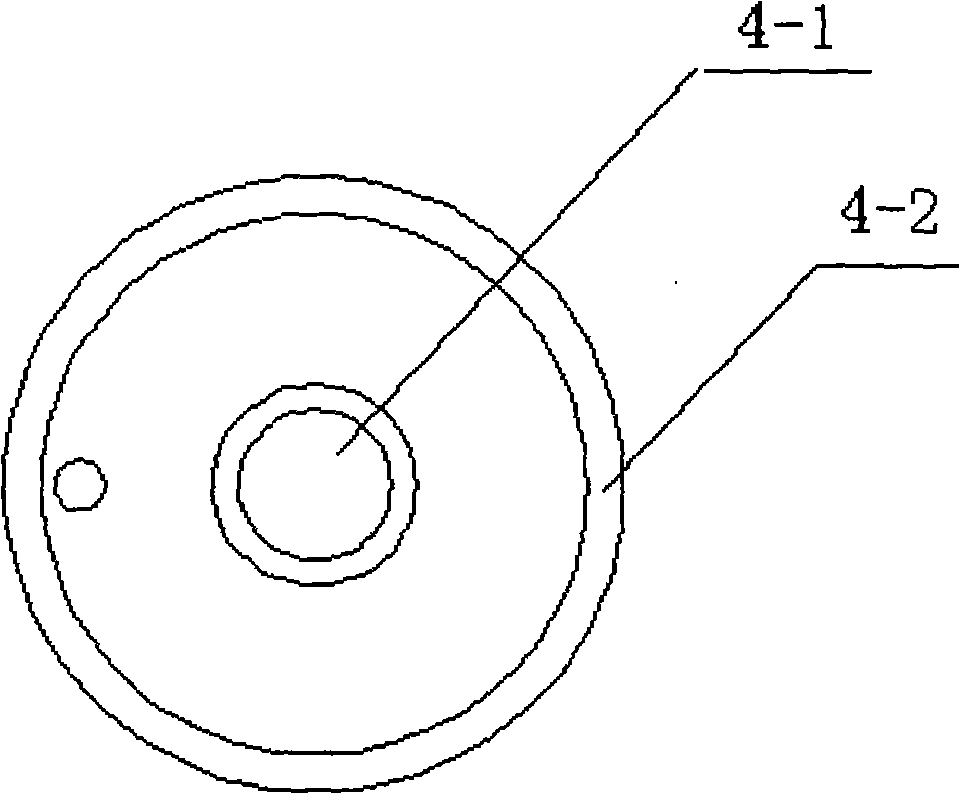

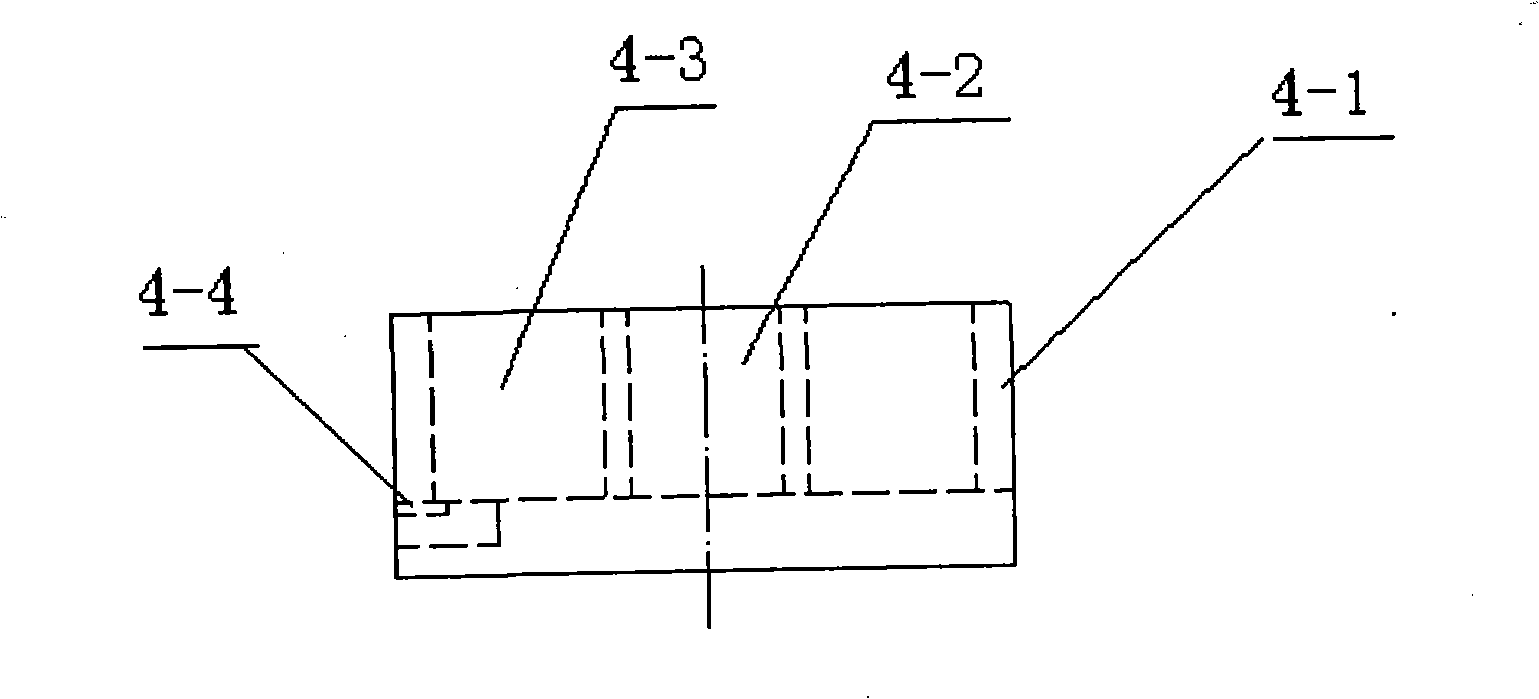

[0026] refer to figure 1 As shown, a fiber grating bolt force measuring device includes a pressure gauge 1, the pressure gauge 1 is connected to the T-shaped oil pipe 2, the horizontal pipe of the T-shaped oil pipe 2 is connected to the hydraulic cylinder 4, and the anchor rod is inserted into the hydraulic cylinder 4. In the inner hole, the vertical tube of the T-shaped oil pipe 2 is connected to the fiber grating sensor 3. The fiber grating sensor 3 includes a shell 5 connected with a cladding 6, and a fiber core 7 is placed in the cladding 6 inner cavity. The fiber core 7 is connected with at least two gratings 8 at intervals, and both ends of the fiber core 7 are connected to a fiber grating sensor network analyzer, and the fiber grating sensor network analyzer is connected to a computer.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com