Cleaning blade, and cleaning apparatus, process cartridge, and image forming apparatus using the same

A technology for cleaning scrapers and imaging devices, applied in electrography, optics, instruments, etc., can solve problems such as inability to maintain cleaning performance for a long time, increased torque of photoreceptor drive system, and increased friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example -

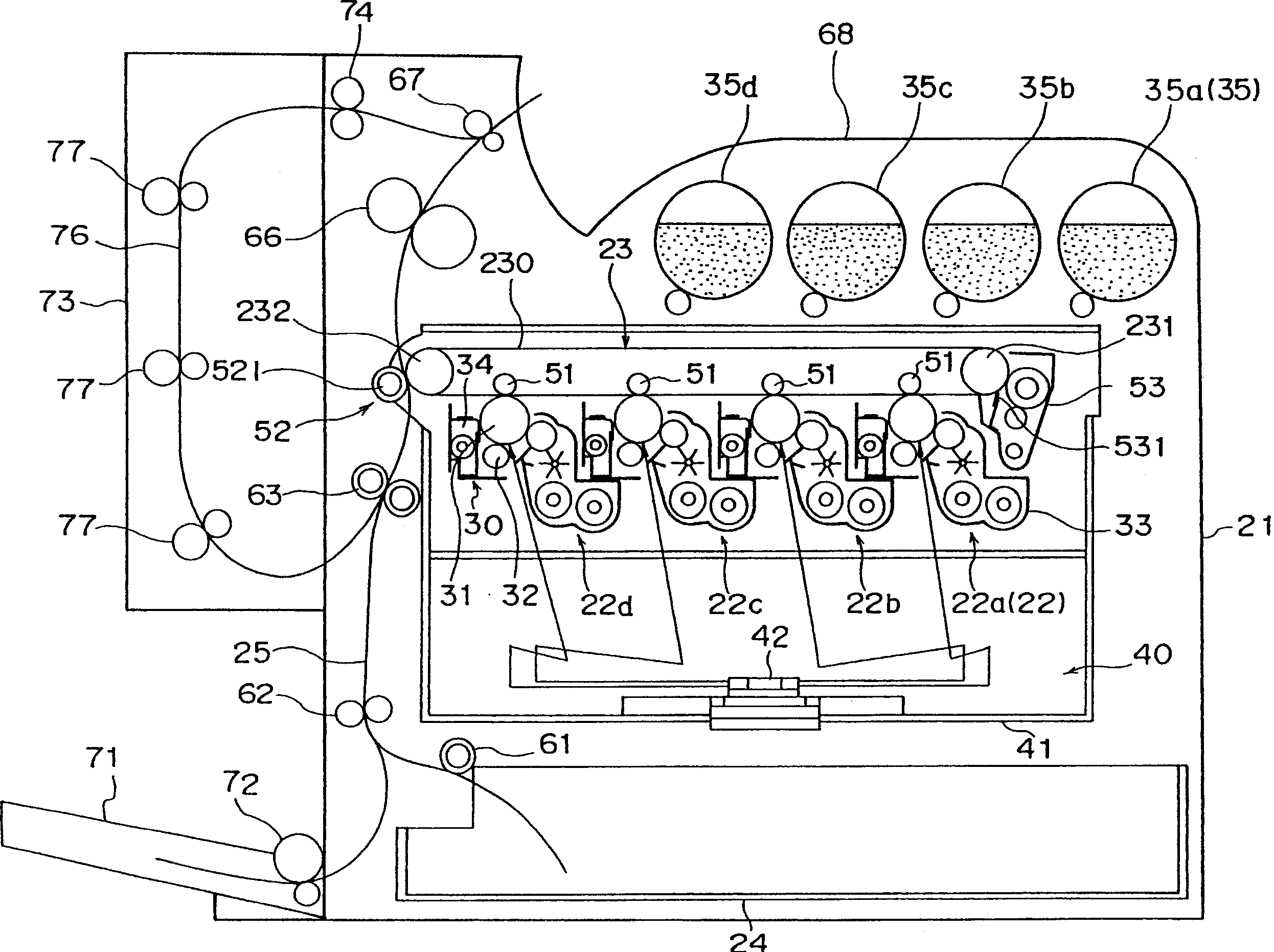

[0166] Next, together with the Figure 1 Specific examples of the cleaning blade, the image forming apparatus using the cleaning blade, and the cleaning apparatus of the present invention will be described in detail starting from the beginning.

[0167] figure 1 is a schematic diagram showing an example of the imaging device of the present invention, a so-called tandem type imaging device.

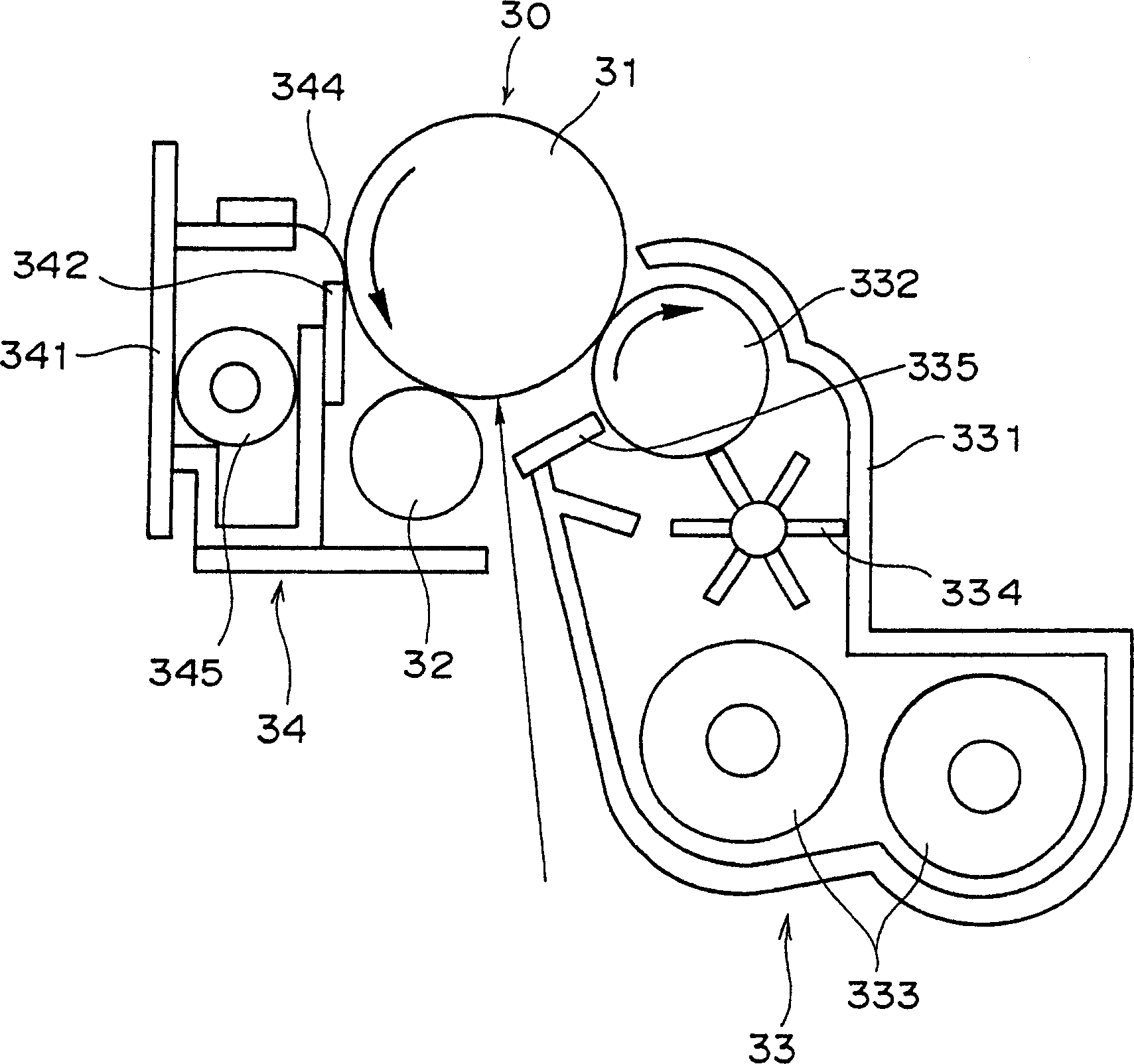

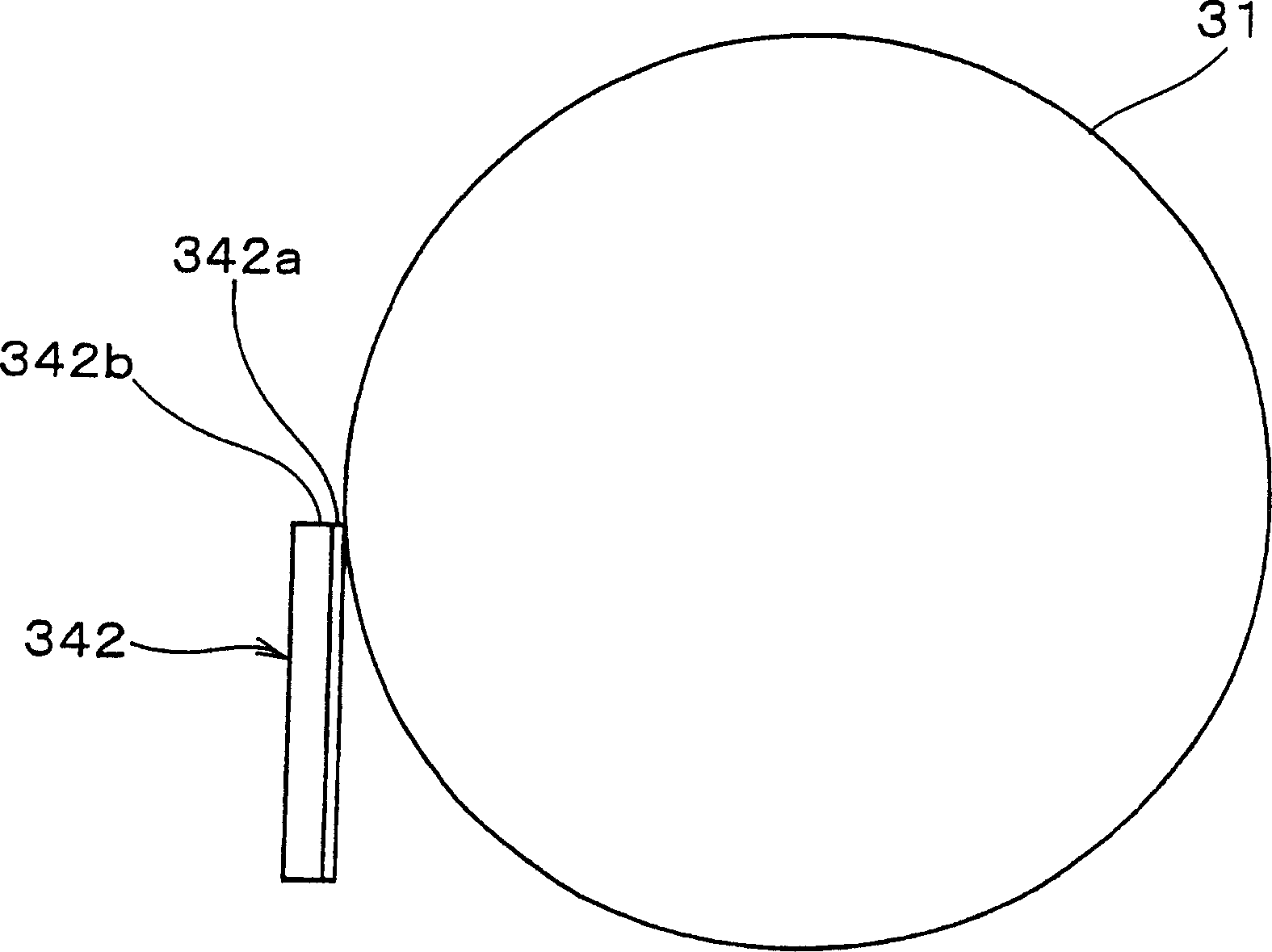

[0168] figure 1 Among them, 21 is a main body casing; 22, 22a to 22d are imaging engines; 23 is a belt assembly; 24 is a recording material supply box; 25 is a recording material conveying path; 30 is each photosensitive body unit; 34 is a cleaning device; 35, 35a to 35d are toner cartridges; 40 is an exposure unit; 41 is a unit case; 42 is a polygonal mirror; 51 is a primary transfer device; 52 is a secondary transfer device; 53 is a belt cleaning device; 61 is a paper feed roller; 62 is a paper pickup roller; 63 is a registration roller (resist roll); 66 is a fixing device; 67 is a pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com