Dual loading port semiconductor processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

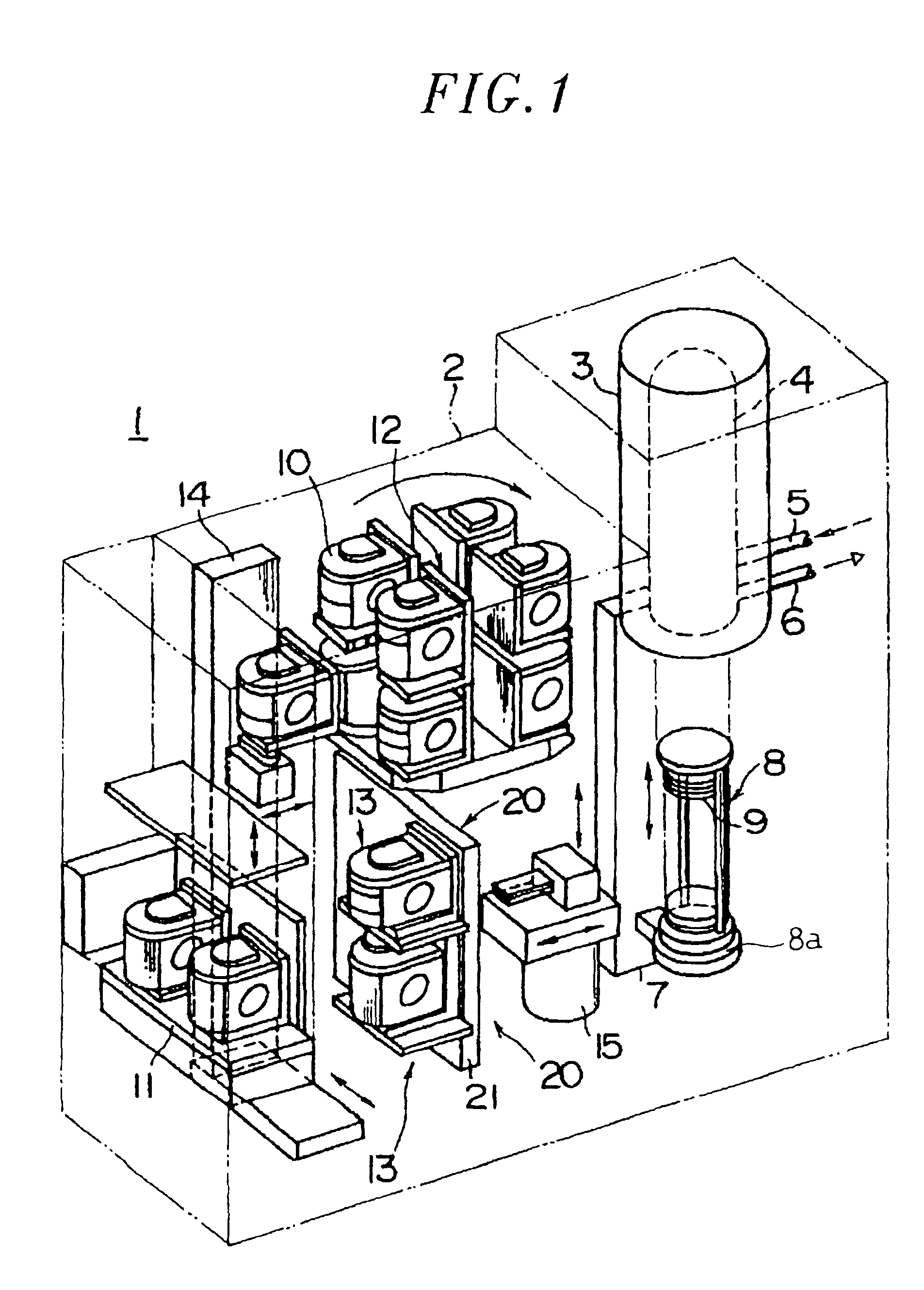

[0048]FIG. 7 illustrates the pod transferring process between the pod shelf 12 and the wafer loading ports 13 and also the wafer transferring process between the pods on the wafer loading ports 13 and the wafer boat 8 in accordance with the present invention.

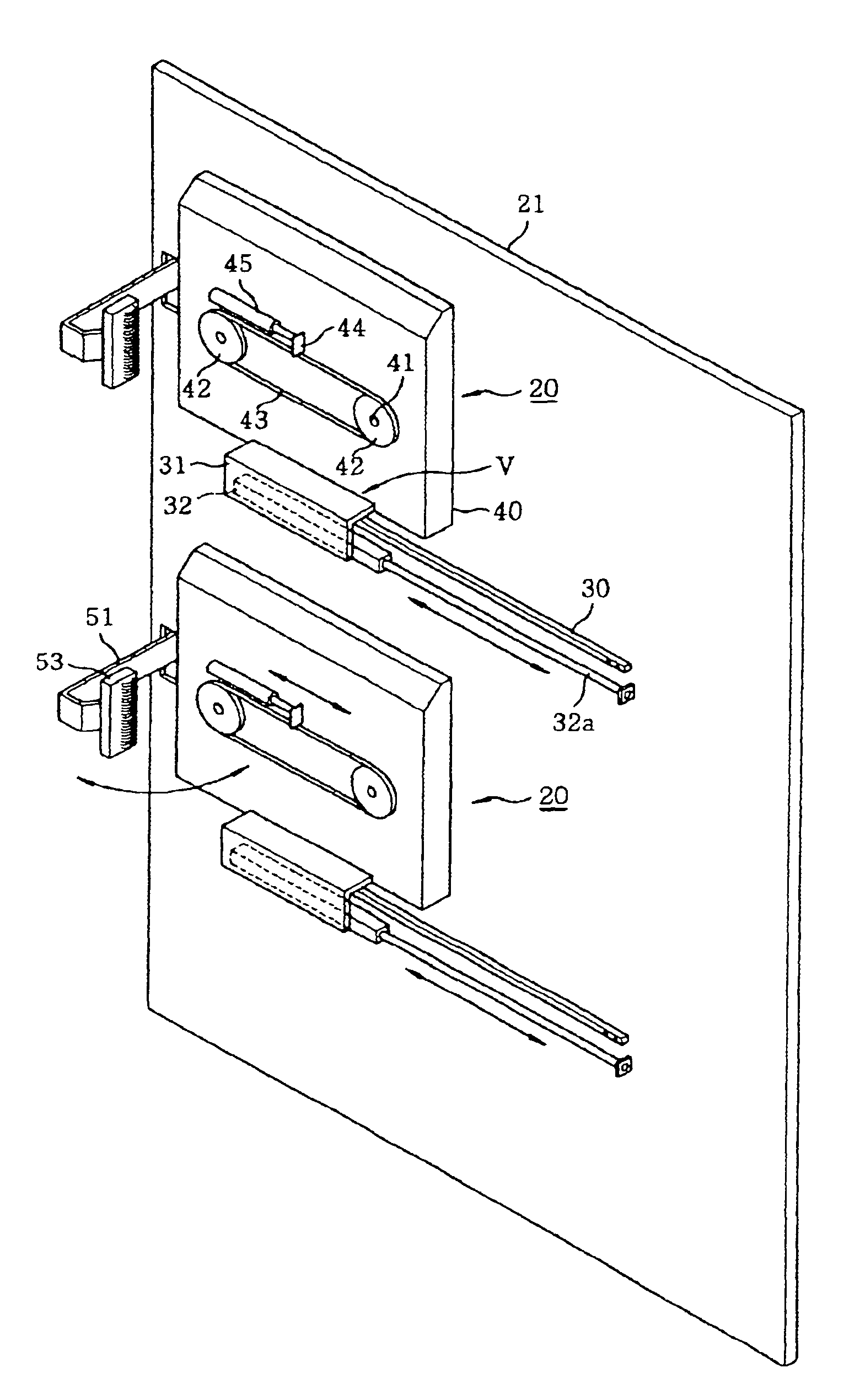

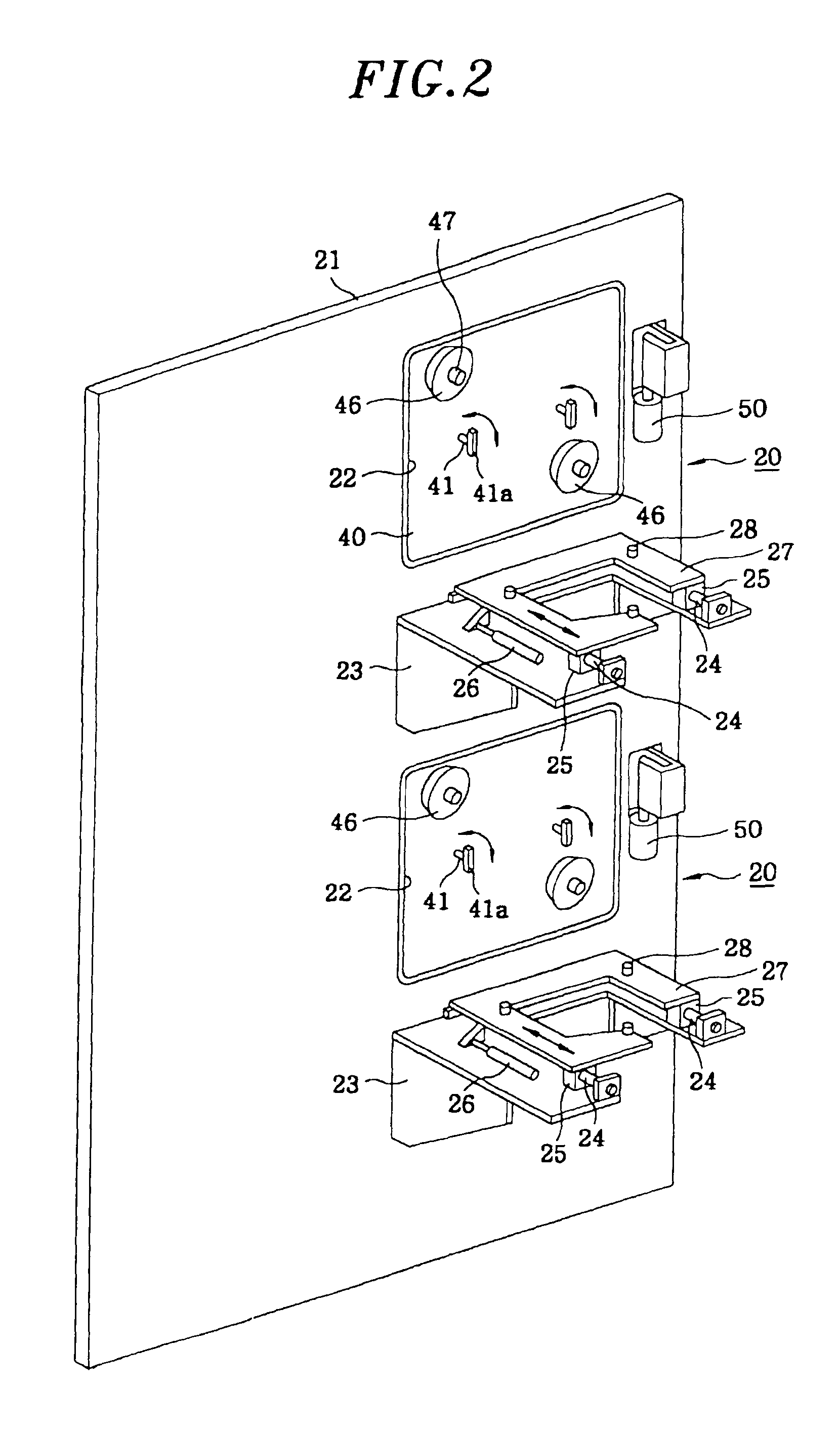

[0049]The two pod openers 20 are arranged to close the openings 22 such that the packing member 55 seals against the rear side wall of the bulkhead 21. One pod 10 is transferred from the pod shelf 12 to, e.g., the upper wafer loading port 13 by the pod handler 14 and disposed on the loading platform 27. The three alignment pins 28 on the loading platform 27 engage with the corresponding three holes (not shown) formed under the pod 10 to thereby complete the alignment of the pod 10 on the loading platform 27.

[0050]The pod 10 provided on the loading platform 27 is moved toward the bulkhead 21 by the extension of the air cylinder 26 in such a manner that the respective packing members 54 and 56 are airtightly in contact with the po...

second embodiment

[0074]The wafer transferring sequence in accordance with the present invention will be described with reference to FIG. 8. At the first stage of the sequence for transferring unprocessed wafers to the wafer boat 8, a first pod containing unprocessed wafers is transferred from the pod shelf 12 to a first wafer loading port (process “A”) and the door of the first pod is opened (process “B”).

[0075]Immediately thereafter at the second stage, wafer transferring from the first pod to the wafer boat 8 (process “D”) starts and, at the same time, a second pod containing the unprocessed wafers are transferred to a second wafer loading port (process “A”) and waits until the wafer transferring process “D” at the first wafer loading port is completed (process “F”).

[0076]At the third stage, the door of the second pod is opened (process “B”) and the wafers therein are transferred to the boat 8 (process “D”) and the door is restored on the empty first pod (process “E”), which is then replaced with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com