Suction nozzle of electronic atomizer

An electronic atomization and inhaler technology, which is applied to inhalers, therapeutic atomizers, smokers' supplies, etc., can solve the problems of curved atomization gas path, laborious inhalation, and comparative manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

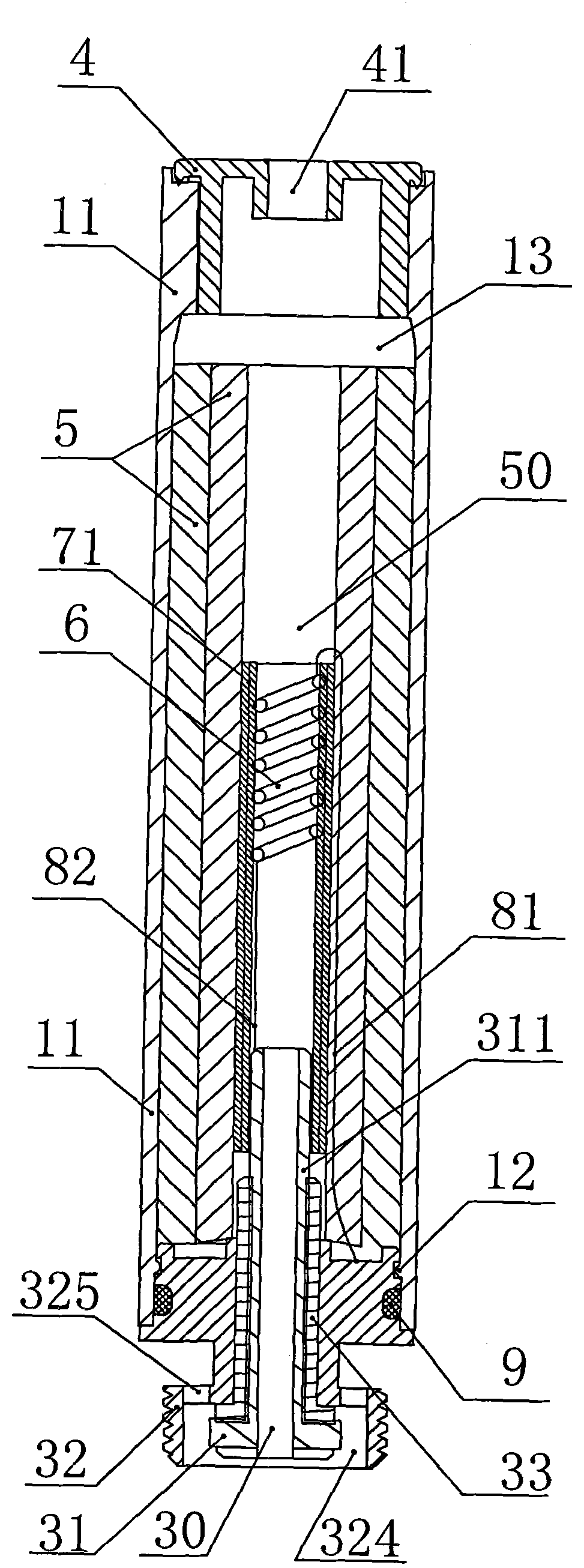

[0041] The specific implementation of the product applying the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

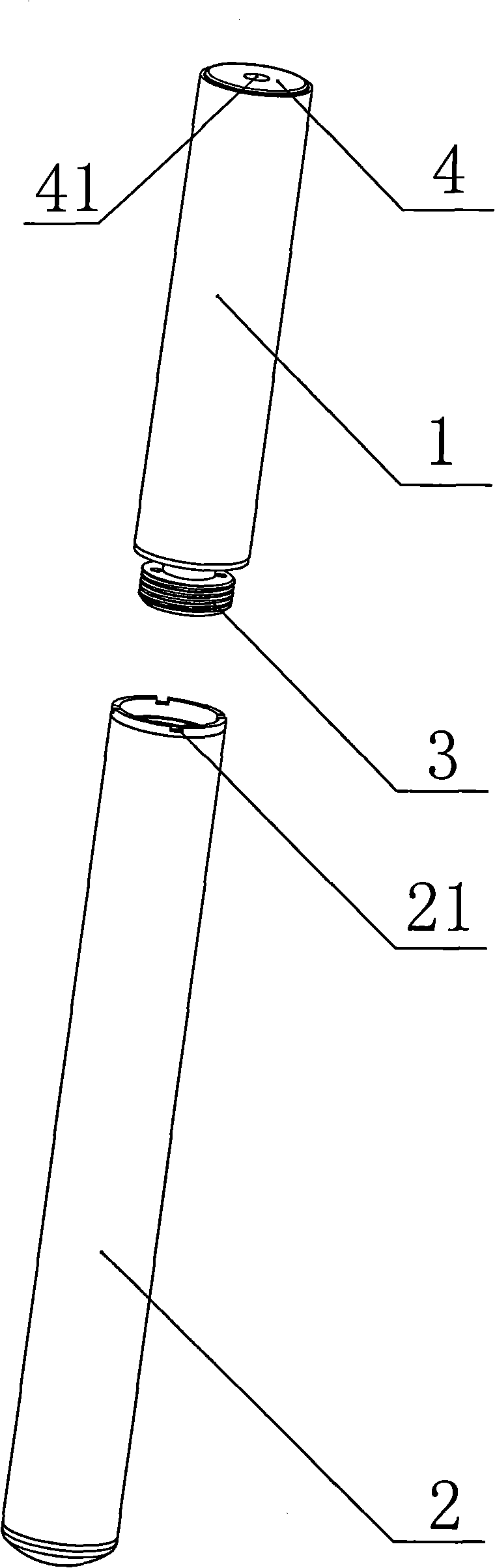

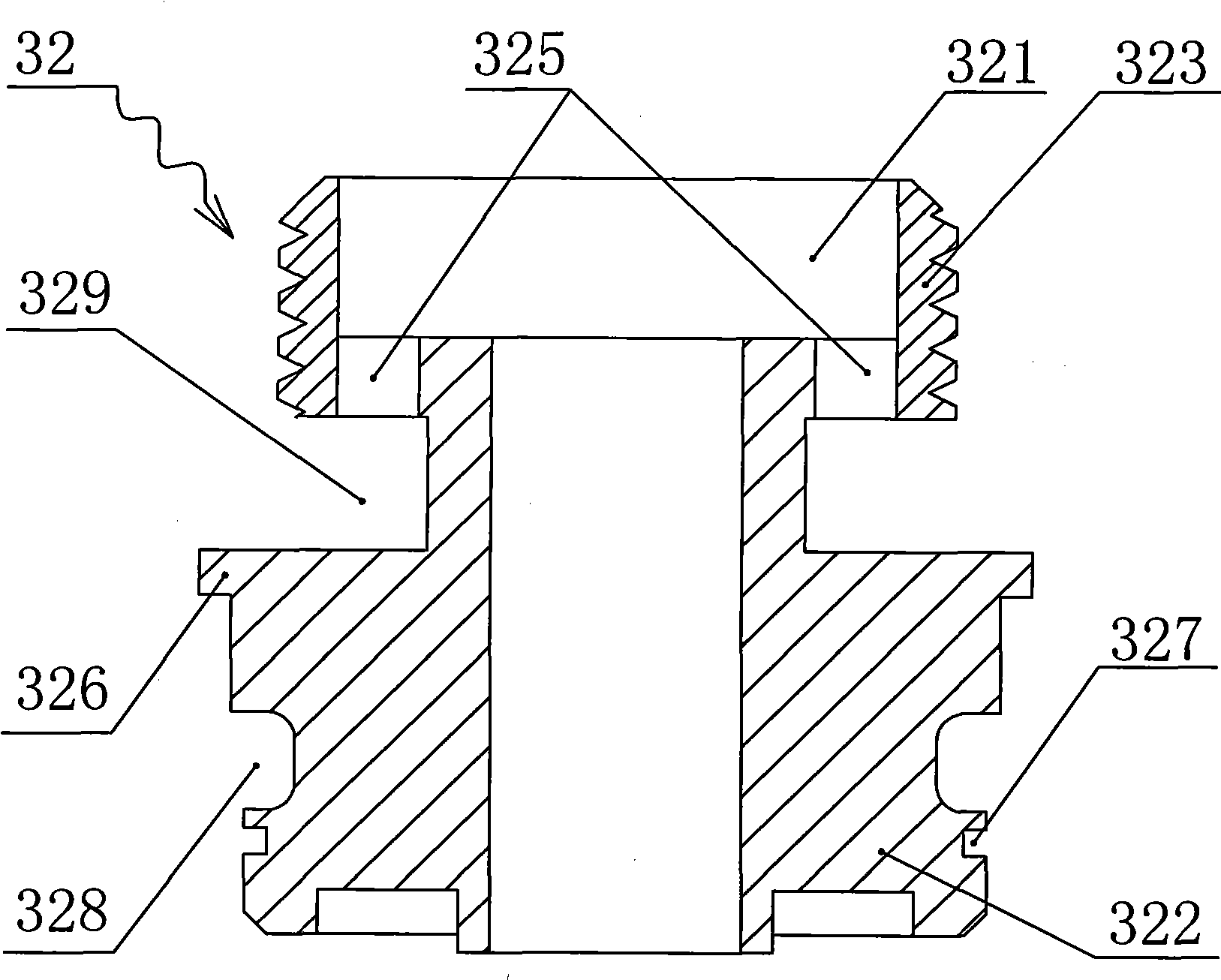

[0042] like figure 1 As shown, an electronic atomization inhaler is an appliance that can atomize the liquid in it so that consumers can inhale the atomized gas. It includes a suction nozzle 1 and a power control part 2, both of which are rod-shaped. Wherein the power control part 2 includes a power supply, a control circuit, etc. and the control power part 2 provides electric energy to the suction nozzle 1; the power control part 2 includes a power supply rod body and a rod body thread electrode, and the rod body thread electrode is buried At the end of the power supply rod body of the power control part 2; secondly, three semicircular holes 21 are symmetrically arranged on the wall end face of the outer electrode of the rod body threaded electrode, when the rod body threaded electrode is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com