Deformation high-temperature alloy capable of forming composite corrosion-resistant layer and preparation process of deformation high-temperature alloy

A technology of deformed superalloy and preparation process, which is applied in key components of high-temperature gas-cooled reactors, hydrogen production conversion furnace, deformed superalloy and its preparation process, thermal power advanced ultra-supercritical unit over/reheater field, and can solve Z-phase Problems such as grain boundary nucleation, harmful alloy processing performance, unfavorable alloy coal ash corrosion resistance, etc., achieve excellent high temperature strength, improved stability, and excellent protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] While ensuring the strength performance of the alloy, the addition of W, Nb and other elements is limited to improve its processing performance. Using a vacuum induction furnace to melt the alloy, the obtained alloy includes: Cr: 16%, Co: 15%, Ti: 1.1%, Al: 4.1%, Si: 0.3%, Mn: 0.3%, Nb: 1.0 %, C: 0.04%, and the balance is Ni. Vacuum induction furnace is used for alloy smelting, and the vacuum degree is lower than 5*10 before introducing high-purity argon. -3 . It is then refined using the electroslag remelting process, and finally an alloy ingot is obtained for processing. Ensure that the content of N element in the alloy after electroslag remelting is not higher than 300ppm, and the content of P and S is not higher than 0.03%.

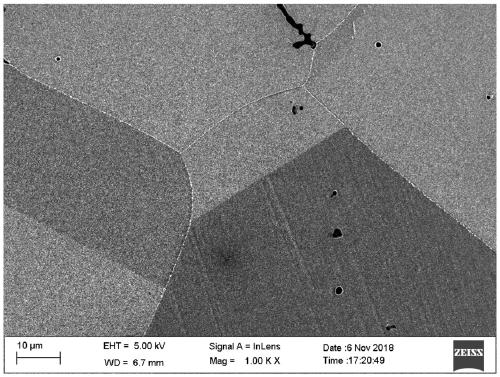

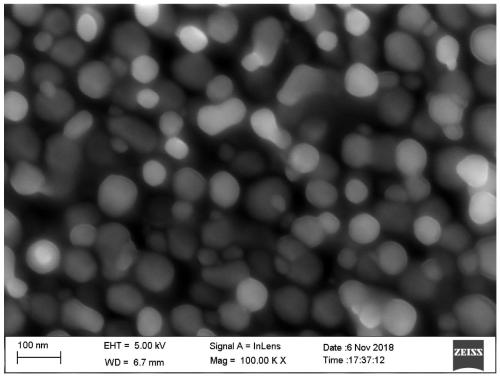

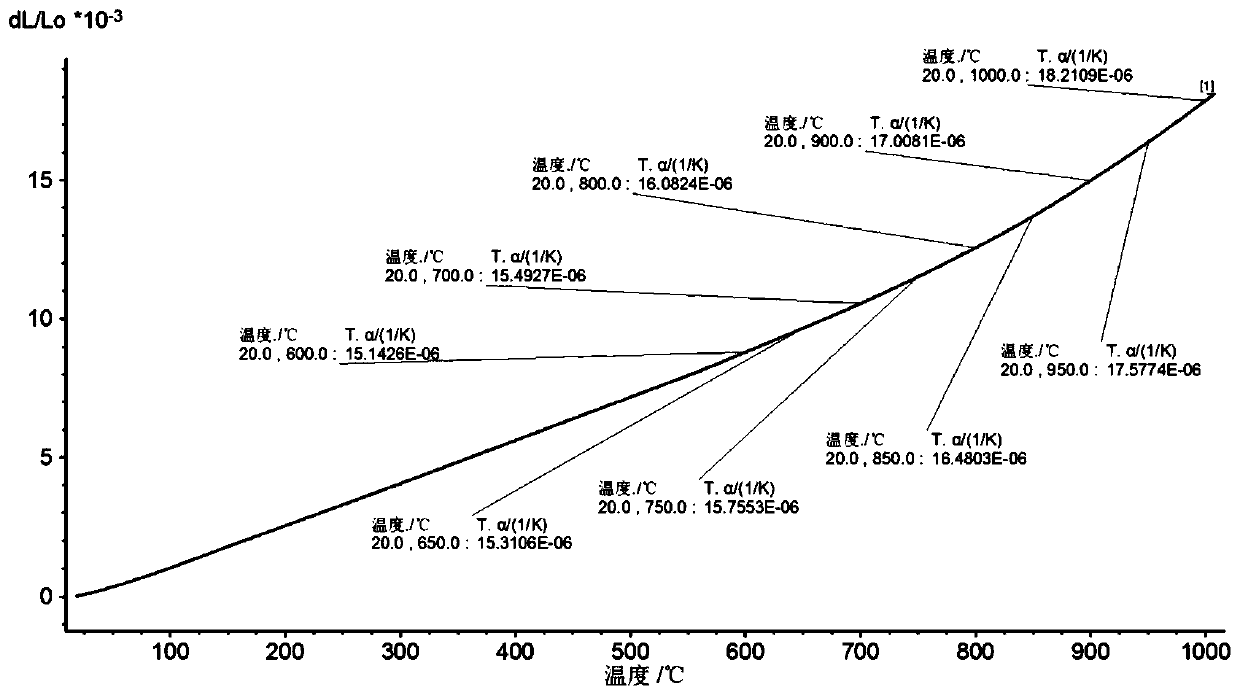

[0040] Homogenize the alloy at 1160°C for 24 hours, then roll it at 100°C above the γ' melting temperature, the total deformation is 95%, and the deformation in each pass is not less than 30%. During the heating process of alloy homogenizat...

Embodiment 2

[0045] While ensuring the strength performance of the alloy, the addition of W, Nb and other elements is limited to improve its processing performance. Using a vacuum induction furnace to melt the alloy, the obtained alloy includes: Cr: 17%, Co: 10%, Ti: 1.5%, Al: 4.0%, Si: 0.2%, Mo: 5.0%, Mn: 0.2 %, Nb: 1.0%, C: 0.04%, and the balance is Ni. Vacuum induction furnace is used for alloy smelting, and the vacuum degree is lower than 5*10 before introducing high-purity argon. -3 . It is then refined using the electroslag remelting process, and finally an alloy ingot is obtained for processing. Ensure that the content of N element in the alloy after electroslag remelting is not higher than 300ppm, and the content of P and S is not higher than 0.03%.

[0046] Homogenize the alloy at 1200°C for 24 hours, then roll it at 100°C above the γ' melting temperature, the total deformation is 70%, and the deformation in each pass is not less than 25%. During the heating process of alloy h...

Embodiment 3

[0051] 1) Alloy smelting: by mass percentage, Cr: 16%, Co: 15%, Ti: 1.5%, Al: 3.5%, W: 0.5%, Mo: 3.0%, Si: 0.3%, Mn: 0.1% , Nb: 0.5%, C: 0.04%, and the balance is Ni; put it into a vacuum induction furnace, carry out alloy smelting and refining under the protection of vacuum and argon, and finally obtain an alloy ingot; the quality of N element in the alloy ingot is 100% The content of P and S is not higher than 0.03%, and the mass percentage content of P and S is not higher than 0.03%.

[0052] 2) High-temperature rolling: After the alloy ingot is raised to 950°C at a heating rate of 10°C / min and held for 1.0 hour, the alloy ingot is homogenized at 1160°C for 72 hours, and then its exterior is coated with a thickness of 0.5 -1.0mm 304 stainless steel jacket, in Ni 3 High-temperature rolling is carried out at 50°C above the Alγ’ dissolution temperature, and the deformation amount of each pass is not less than 25%, and the total deformation amount is not less than 70%.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com