Preparation method of hydrogel electrolyte for aqueous zinc ion energy storage battery

A technology for energy storage batteries and hydrogels, which is applied in the field of preparation of hydrogel electrolytes for water-based zinc-ion energy storage batteries. Chemical properties and other issues, to achieve fast and easy performance, high yield, good stretching and bending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

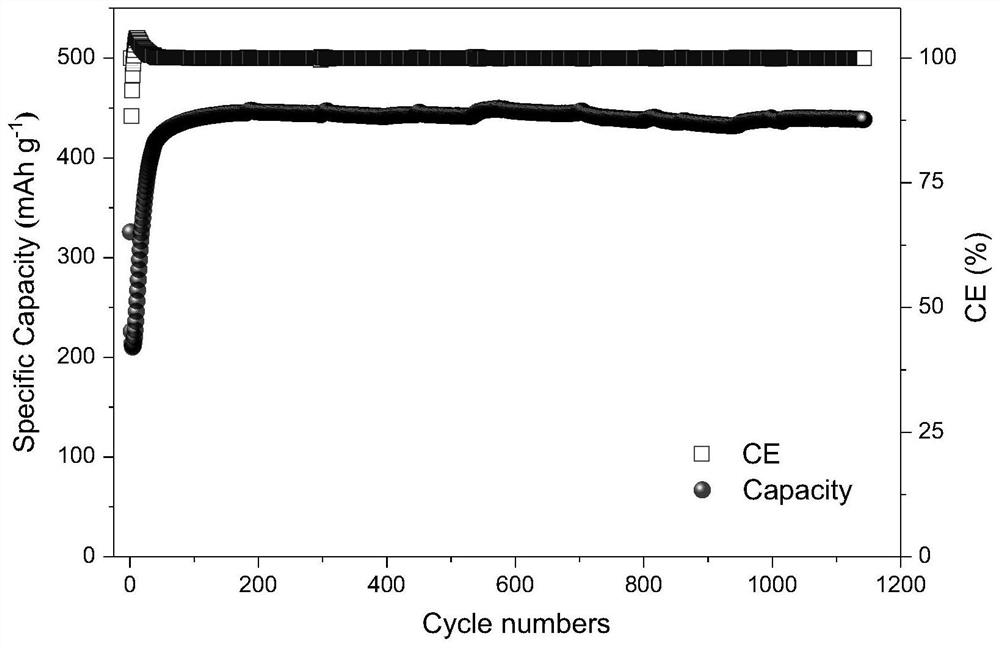

Embodiment 1

[0028] Add 2g polyacrylamide to 10ml concentration and be 4mol / kg Zn(ClO 4 ) 2 In the solution, stir until dissolved to obtain solution A; add 3 mg methylene bisacrylamide and 2 mg ammonium persulfate to solution A in sequence, after stirring thoroughly, heat at 60°C for 30 minutes to form hydrogel B; hydrogel B At a concentration of 4mol / kg Zn(ClO 4 ) 2 soaking in the solution for 20 minutes to obtain a hydrogel electrolyte for a water-based zinc ion energy storage battery. The hydrogel electrolyte prepared above has a porous structure with a pore diameter of 100-500 nm. The hydrogel electrolyte has a tensile elongation of 700% and a water absorption of 400%.

Embodiment 2

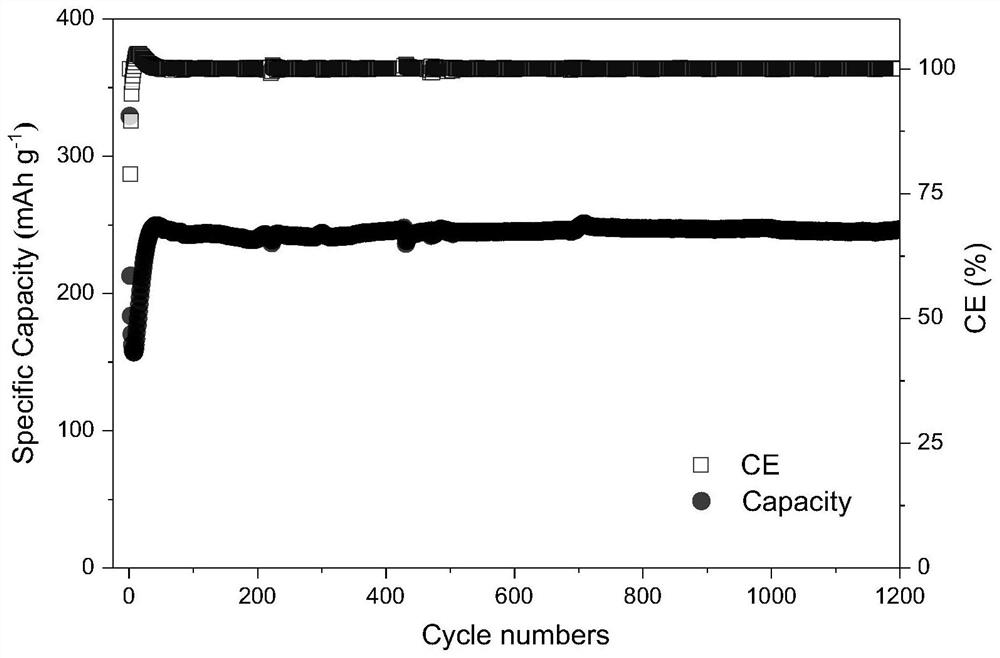

[0030] Add 2g of polyacrylamide to 10ml of ZnSO with a concentration of 4mol / kg 4 In the solution, stir until dissolved to obtain solution A; add 3 mg methylene bisacrylamide and 2 mg ammonium persulfate to solution A in sequence, after stirring thoroughly, heat at 60°C for 30 minutes to form hydrogel B; hydrogel B At a concentration of 4mol / kg ZnSO 4 soaking in the solution for 20 minutes to obtain a hydrogel electrolyte for a water-based zinc ion energy storage battery. The hydrogel electrolyte prepared above has a porous structure with a pore diameter of 200-800 nm. The hydrogel electrolyte has a tensile elongation of 400% and a water absorption of 200%.

Embodiment 3

[0032] Add 1g of polyacrylamide to 10ml concentration of 3mol / kg Zn(ClO 4 ) 2 In the solution, stir until dissolved to obtain solution A; add 2mg methylene bisacrylamide and 1mg ammonium persulfate to solution A in sequence, after stirring fully, heat at 80°C for 60min to form hydrogel B; hydrogel B At a concentration of 3mol / kg Zn(ClO 4 ) 2 soaking in the solution for 20 minutes to obtain a hydrogel electrolyte for a water-based zinc ion energy storage battery. The hydrogel electrolyte prepared above has a porous structure with a pore diameter of 100-500 nm. The hydrogel electrolyte has a tensile elongation of 600% and a water absorption of 300%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com