Nickel Hydroxide electrode material with improved microstructure and method for making the same

a technology of nickel hydroxide and electrode material, which is applied in the field of positive electrode material to achieve the effect of improving capacity, rate capability, utilization and/or high temperature performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

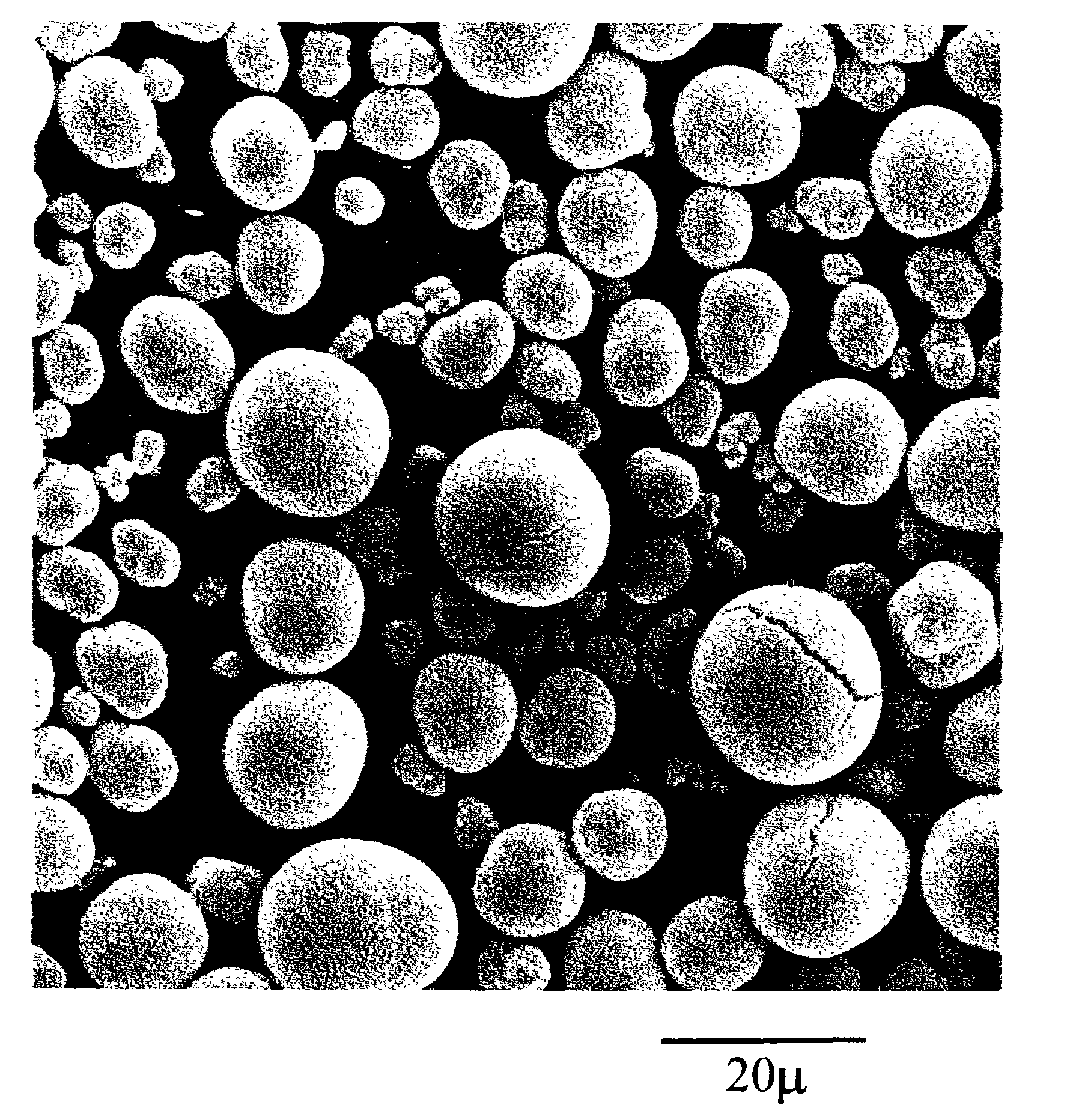

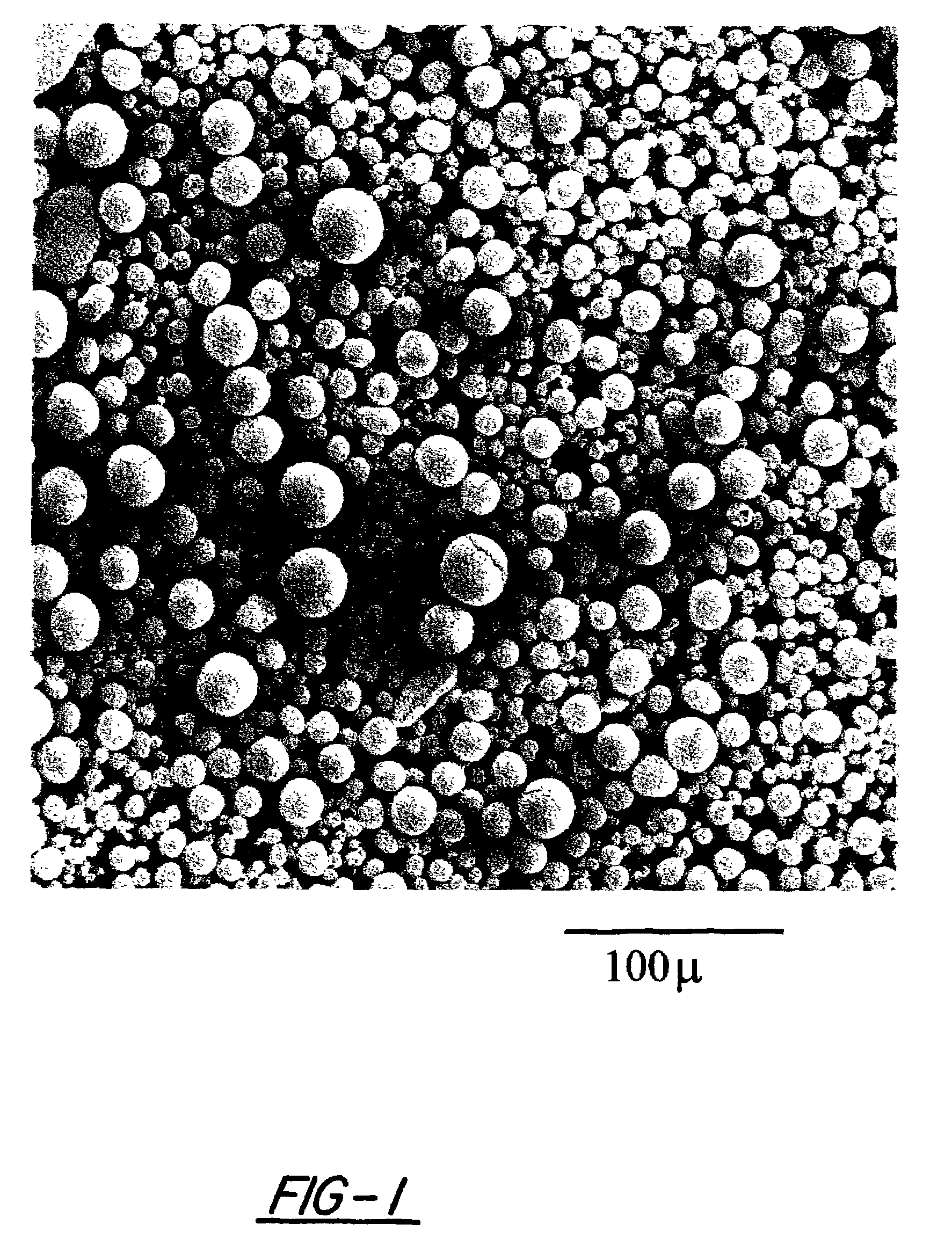

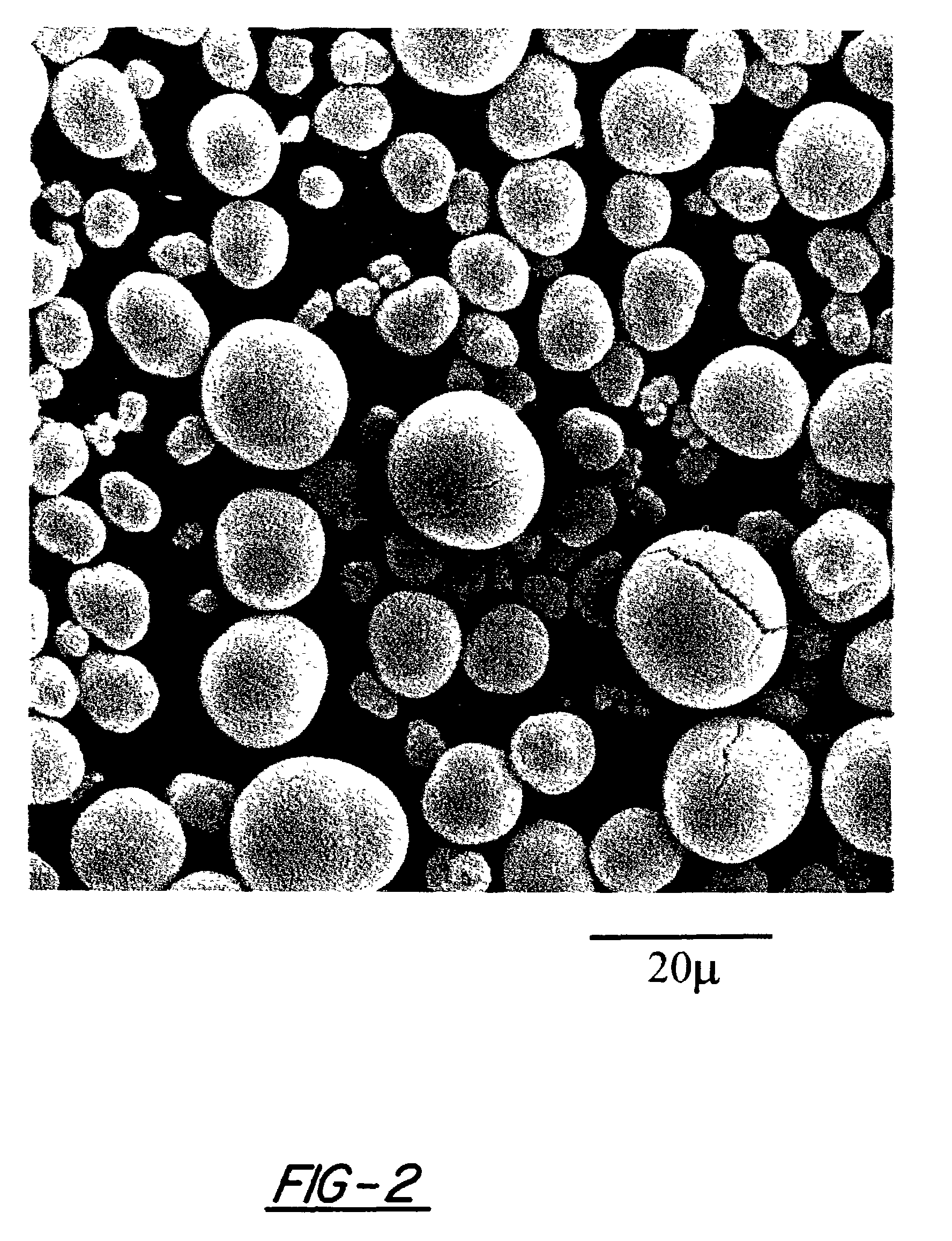

[0124]Slurries of the three formulations of nickel hydroxide material set forth in Table 1 above were formulated in a conventional manner. Such slurry was pasted onto expanded nickel foam, and dried to form positive electrodes. Loading for each of these electrodes is presented in Table 2. The electrodes formed from the modified nickel hydroxide materials of the instant invention were found to have much higher loading factors compared to conventional material. The higher loading of the modified nickel hydroxide materials of the present invention is the result of the uniformly spherical condition of the nickel hydroxide particles and their uniform size distribution (provides for a higher packing density).

[0125]Negative electrodes were fabricated as described in commonly assigned U.S. Pat. No. 5,536,591 (the disclosure of which is specifically incorporated herein by reference).

[0126]The negative metal hydride and the positive nickel hydroxide electrodes were used in flooded half cells ...

example 3

[0129]C type cells as prepared in Example 2 above, were subjected to capacity testing at different temperatures. The results are shown in FIG. 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tap density | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| peak power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com