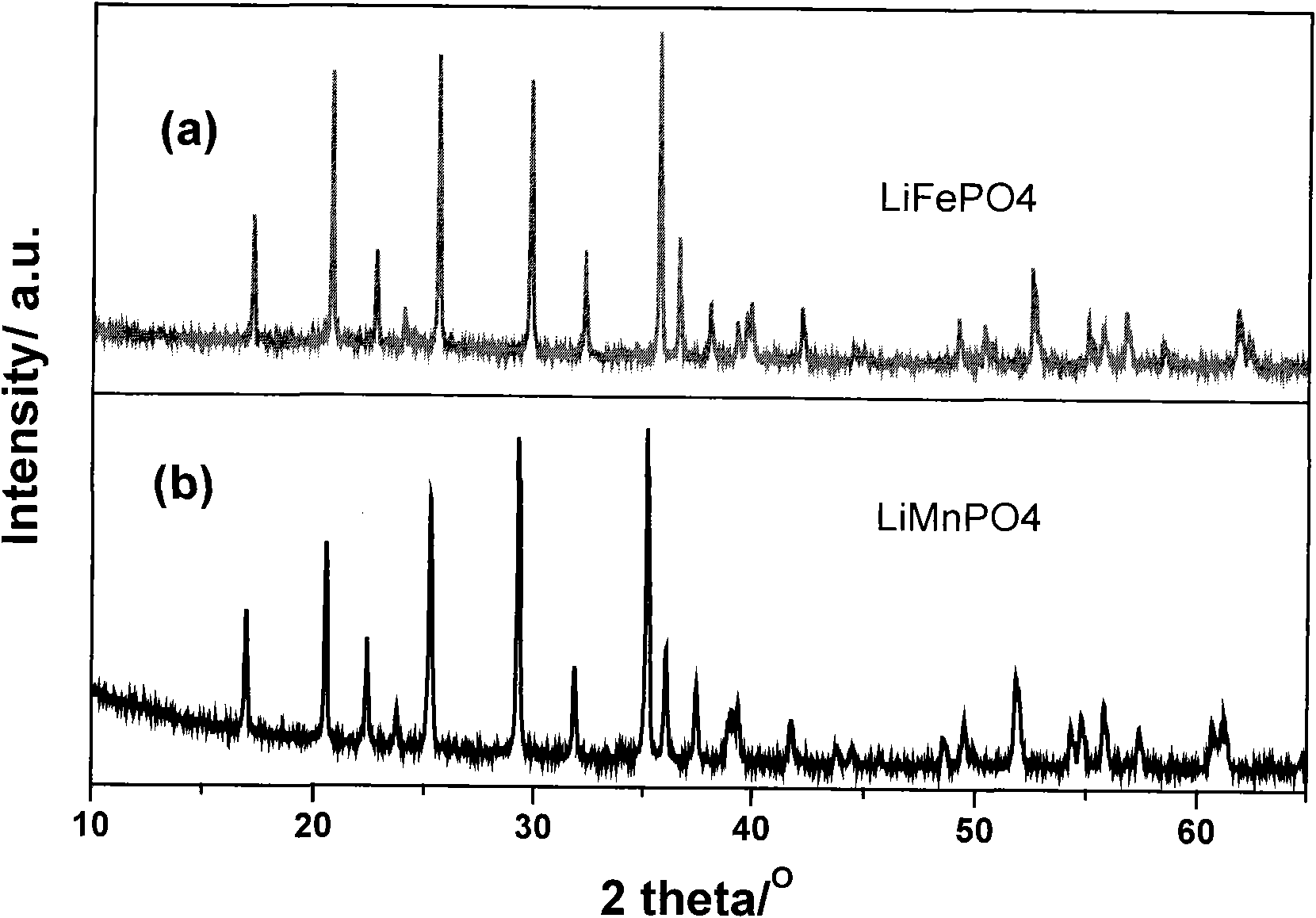

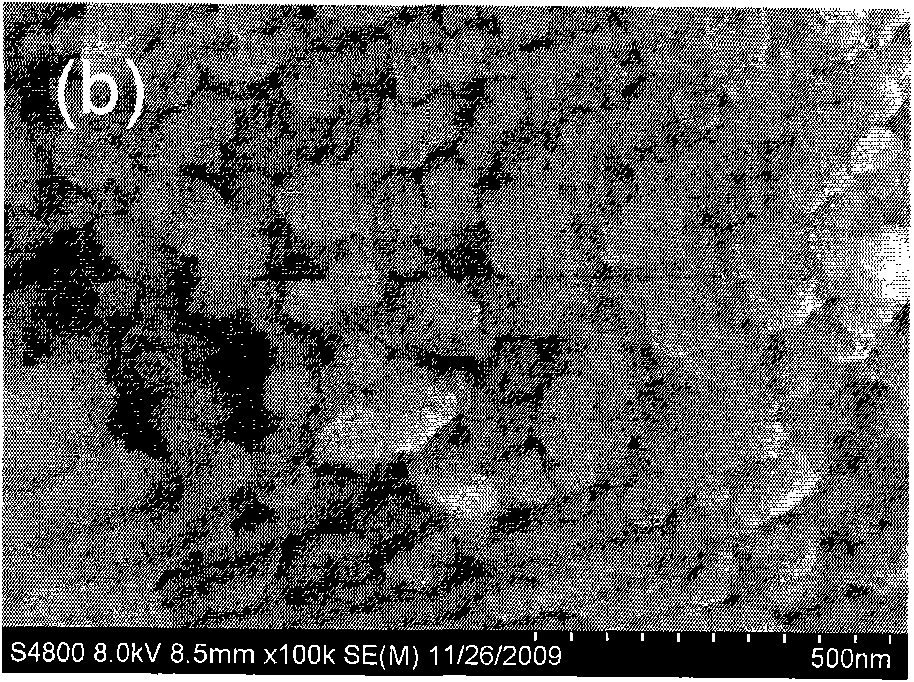

Nano-modified polyanionic cathode active material, preparation method thereof, and lithium ion secondary battery

A cathode active material, polyanion technology, applied in the field of high-performance lithium-ion secondary batteries, can solve the problems affecting the physical and chemical properties of materials such as tap density, specific capacity, easy growth of polyanion materials, and poor discharge performance at high currents. , to achieve the effect of easy preparation and application, high cycle stability, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the positive electrode is to blend the positive electrode active material, the conductive agent and the binder in the solvent, coat the current collector on the current collector after mixing evenly, and form the positive electrode sheet after drying. The positive active material used here is nano-modified polyanion and its composite material. The conductive agent can be conductive carbon material, such as conductive carbon black, Super P, and the current collector is aluminum foil.

[0046] The preparation method of the negative electrode is that the negative electrode active material and the binder are blended in a solvent, mixed evenly, coated on the current collector, and dried to form a negative electrode sheet. Negative electrode active material active material can be metal lithium; Carbon material, as graphite, pyrolytic carbon, coke, carbon fiber and high-temperature sintered organic polymer compound etc.; , Al, Ga, In, Si, Sn, Pb, Sb,...

Embodiment 1

[0049] The first step is to disperse ferrous oxalate, ferric oxide and lithium dihydrogen phosphate in a molar ratio of 0.9:0.1:1 in a certain amount of water, and add 20% sucrose of the above-mentioned solid mass, the solid content is 20%, and then Then ball milled in a ball mill at a speed of 500 rpm for 20 hours, and the mass ratio of solids to balls was 1:10. The mixture was spray-dried to obtain a composite electrode material precursor.

[0050] In the second step, the precursor powder is pretreated at 350°C for 1-4 hours under argon protection, then heat-treated at 400-450°C for 1-10 hours, and then heat-treated at 450-550°C for 1-10 hours, Finally, heat treatment at 550-900° C. for 1-10 hours to obtain nanometer lithium iron phosphate polyanion material.

[0051] The third step is to mix the nano-lithium iron phosphate polyanion positive electrode active material with the conductive agent Super P and the binder polyvinylidene fluoride in nitrogen methyl pyrrolidone in ...

Embodiment 2

[0053] The first step is to disperse ferrous oxalate, iron oxide and lithium dihydrogen phosphate in a molar ratio of 0.5:0.5:1.0 in a certain amount of water with a solid content of 20%, and then put them in a ball mill at a speed of 500 rpm After ball milling for 20 hours, the mass ratio of solids to balls was 1:10. The mixture was spray-dried to obtain a composite electrode material precursor.

[0054] The second step is the same as the second step of Example 1, and a doped nano polyanion lithium iron phosphate electrode material is prepared.

[0055] Subsequent steps are the same as the third step in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com