Method for preparing nano-stage naphthylamine sulfonate and aniline copolymer

A technology of aniline copolymer and naphthylamine sulfonate, applied in the field of preparing nano-scale naphthylamine sulfonate and aniline copolymer, achieving good yield and universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 0.0893g (0.4mmol) of 7-sulfonic acid-1-naphthylamine to 20mL aqueous solution containing equimolar NaOH (0.4mmol), and then add 0.328mL (3.6mmol) of aniline after complete dissolution, at 20°C Rapid magnetic stirring in a constant temperature water bath for 30 min. Then, 20 mL of aqueous solution dissolved with 1.3692 g (6 mmol) of ammonium persulfate was slowly dropped into the monomer solution at a speed of 3 seconds / drop, and it took 20 minutes to complete the drop. After a few drops of the oxidant were added, the reaction solution changed from light red to wine red, then dark red and gradually deepened, and gray-black particles were formed after 15 minutes. After 20 minutes, the oxidant was added dropwise, and the reaction was continued for 48 hours in a constant temperature water bath at 20°C. After the reaction, the reaction solution was a black opaque system, and 1 mL of the stock solution was taken into a vial for particle size analysis. The rest of the so...

Embodiment 2~6

[0034] The following examples will illustrate the effect of different monomer molar ratios on the polymerization yield and polymer size in the present invention.

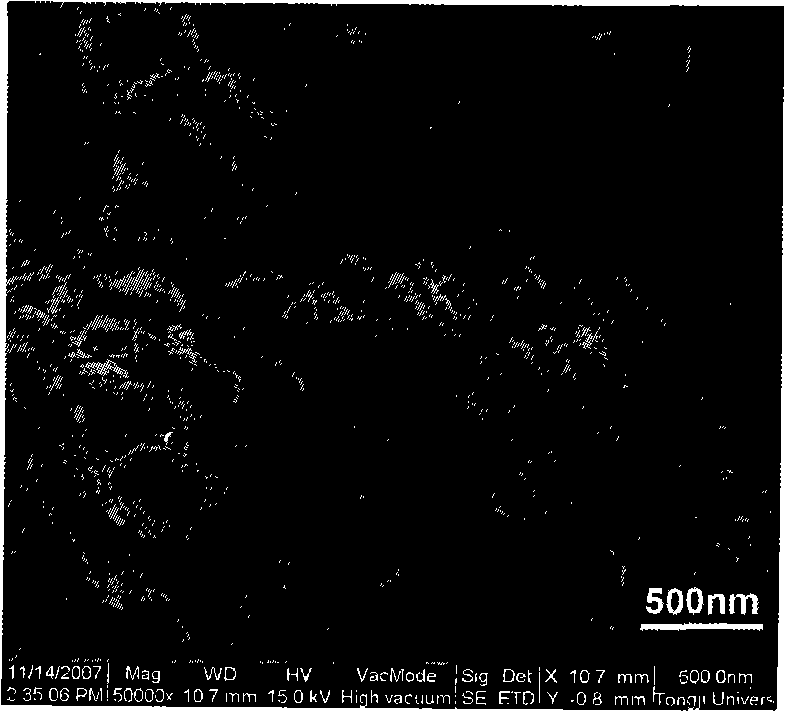

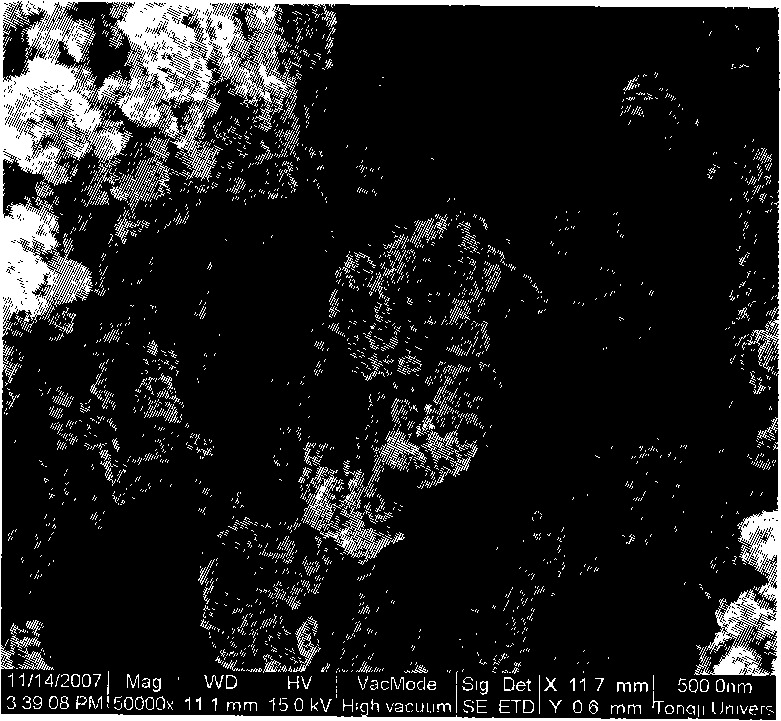

[0035] Repeat Example 1, but change the molar ratio of aniline and 7-sulfonic acid-1-naphthylamine so that the molar ratio of aniline and 7-sulfonic acid-1-naphthylamine is 65:35, 70:30, 95:5, 98:2, 100:0, the yields of the obtained polymers were 57.9wt%, 60.7%, 104.9wt%, 105.7%, 104.0wt%, respectively. Analyzed by a laser particle size analyzer, the average particle diameters of the obtained polymers were 121 nm, 68 nm, 151 nm, 2.7 μm, and 3.93 μm, respectively. And the SEM and TEM characterization results are as follows figure 1 , figure 2 , image 3 As shown, the morphologies of the polymers are shown as nanoblocks, nanorods, and nanoparticles, respectively. The cross-sectional diameter of the nanorods is about 31-63 nm.

Embodiment 7~9

[0037] The following examples will illustrate the effect of different oxygen ratios on the polymerization yield and polymer size in the present invention.

[0038]Repeat Example 1, and the reaction time is shortened to 24h. When changing the amount of oxidizing agent added, the ratio of oxidizing agent to monomer is 0.5:1, 1:1, 1.25:1, and the yields of polymer obtained are respectively 16.4wt%, 61.6wt%, 82.7wt%. Analyzed by a laser particle size analyzer, the average particle diameters of the obtained polymers were 309 nm, 162 nm, and 2.696 μm, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com