Small-sheet-diameter graphene powder, graphene conductive paste, preparation method of graphene conductive paste, and application

A technology of graphene powder and conductive paste, which is applied in the field of graphene, can solve the problems of difficulty in realizing industrialized production and popularization and application, difficulty in optimizing the energy density of ternary batteries, and insignificant graphene characteristics, etc., so as to be suitable for industrialization Promotion and application, low cost, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The present invention also provides a kind of preparation method of graphene powder, comprises the following steps:

[0071] 1) Under the condition of airtight pressure, the graphite is immersed in the supercritical fluid and mixed to obtain the supercritical state mixed liquid;

[0072] 2) After pressurizing the supercritical mixed liquid obtained in the above steps, the graphene powder is obtained after being sprayed and peeled off through a slit.

[0073] The present invention can correspond to the parameters, selection of raw materials and products in the above-mentioned preparation method, and the corresponding optimization principles, and the parameters, selection, and corresponding optimization principles of the raw materials and products in the aforementioned graphene powder. Let me repeat them one by one. The specific process and parameter control in the preparation method of the present invention, and its corresponding optimization principle and the specific ...

Embodiment 1

[0102] Grind 10g of graphite powder with a jet mill for 5 minutes for homogenization to obtain graphite powder with a particle size of 2-4μm, and put the powder into 1L of supercritical CO 2 Soak in the fluid, after 800r / min high-speed stirring, soak for 0.5h, pressurize to 100MPa high-pressure slit peeling, and collect graphene powder with filter cloth.

[0103] The graphene powder prepared in Example 1 of the present invention was characterized.

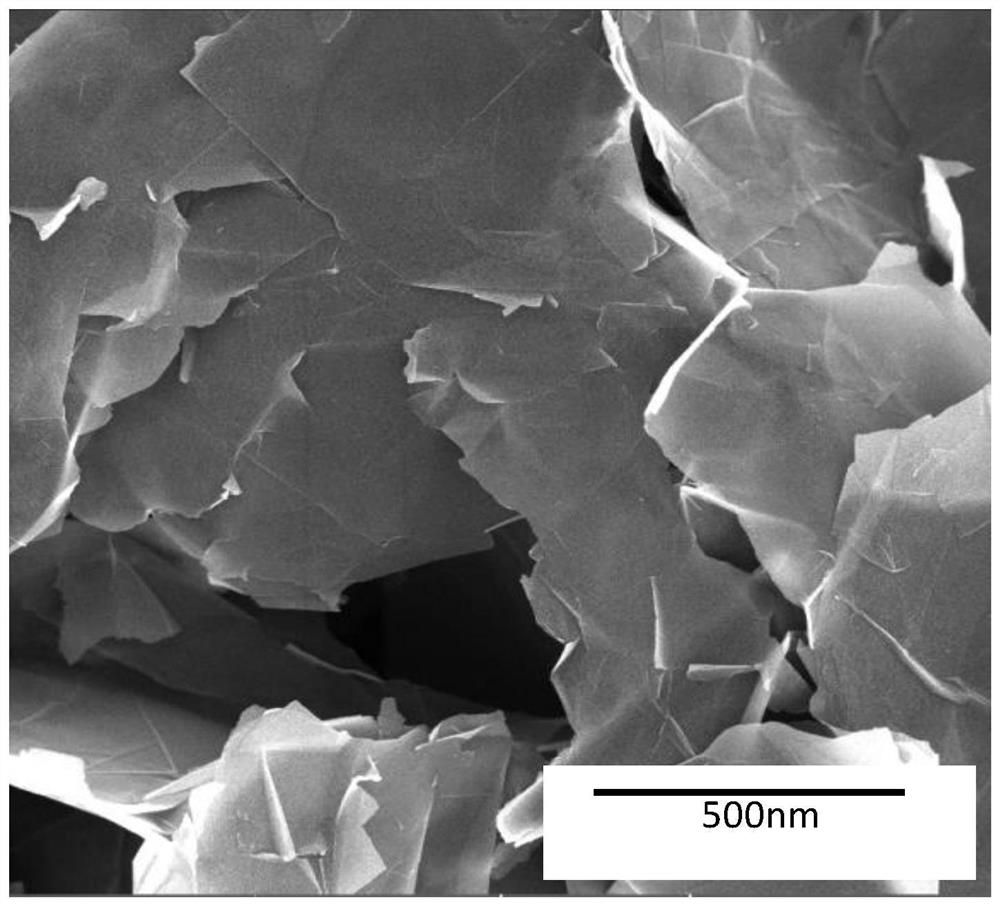

[0104] see figure 1 , figure 1 It is the SEM scanning electron micrograph of the graphene powder prepared in Example 1 of the present invention.

[0105] Depend on figure 1 It can be seen that in the graphene powder prepared by the present invention, the graphene sheet diameter is small, the size is about 600nm, and the sheet thickness is thin.

[0106] After the graphene powder, PVDF and NMP are mixed, they are homogenized and dispersed by a 70MPa high-pressure homogenizer for 30 minutes to obtain a nano-graphene conductive pa...

Embodiment 2

[0131] Grind 10g of graphite powder with a jet mill for 5 minutes for homogenization to obtain graphite powder with a particle size of 2-4μm, and put the powder into 1L of supercritical CO 2 Soak in the fluid, stir at 1000r / min at high speed, soak for 1 hour, pressurize to 100MPa and peel off the high-pressure slit, and collect the graphene powder with filter cloth.

[0132] The graphene powder prepared in Example 2 of the present invention was characterized.

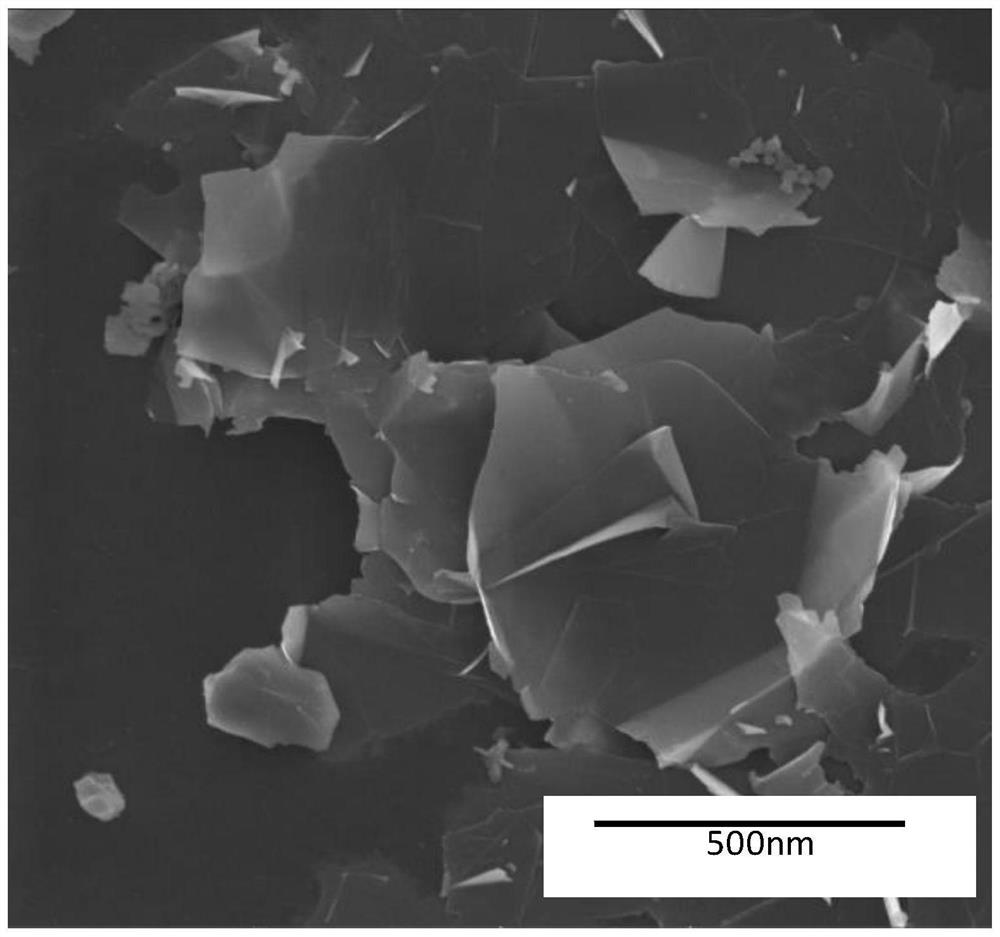

[0133] see image 3 , image 3 SEM scanning electron micrograph of the graphene powder prepared in Example 2 of the present invention.

[0134] Depend on image 3 It can be seen that in the graphene powder prepared by the present invention, the graphene sheet diameter is small, the size is about 500nm, and the sheet thickness is thin.

[0135] After the graphene powder, PVDF and NMP are mixed, they are homogenized and dispersed by a 70MPa high-pressure homogenizer for 30 minutes to obtain a nano-graphene conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com