Manufacturing method of graphene/manganese dioxide super-capacitor electrode

A supercapacitor electrode, manganese dioxide technology, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, chemical instruments and methods, etc. effect and other problems, to achieve the effects of increasing capacitance, charge and discharge efficiency, increasing specific surface area, and strong mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

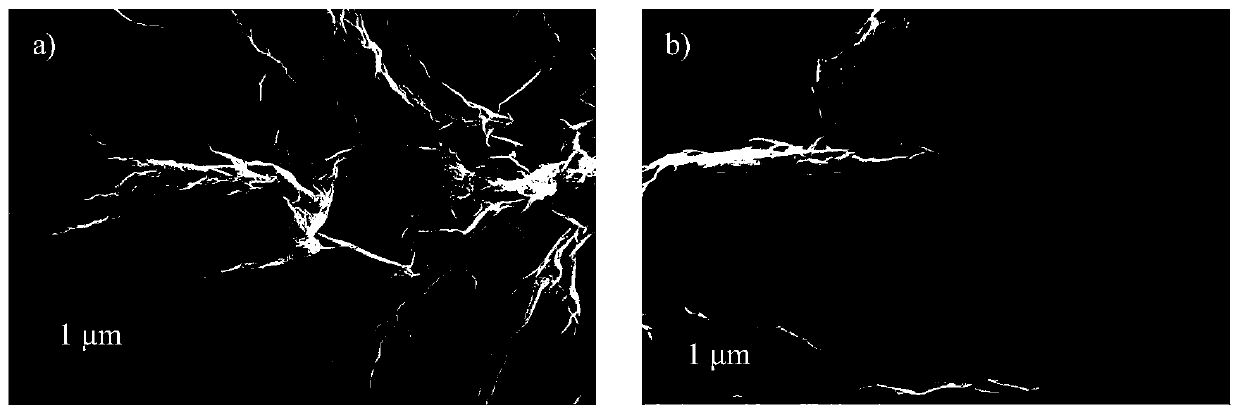

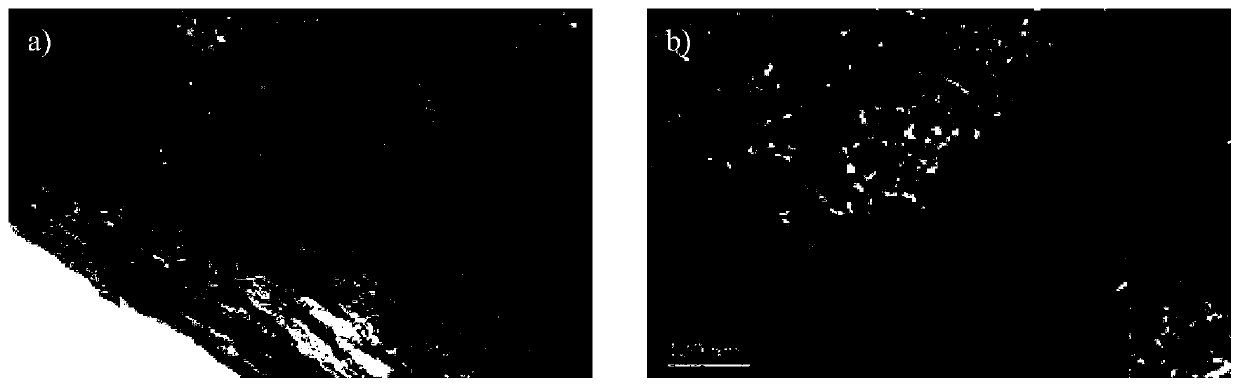

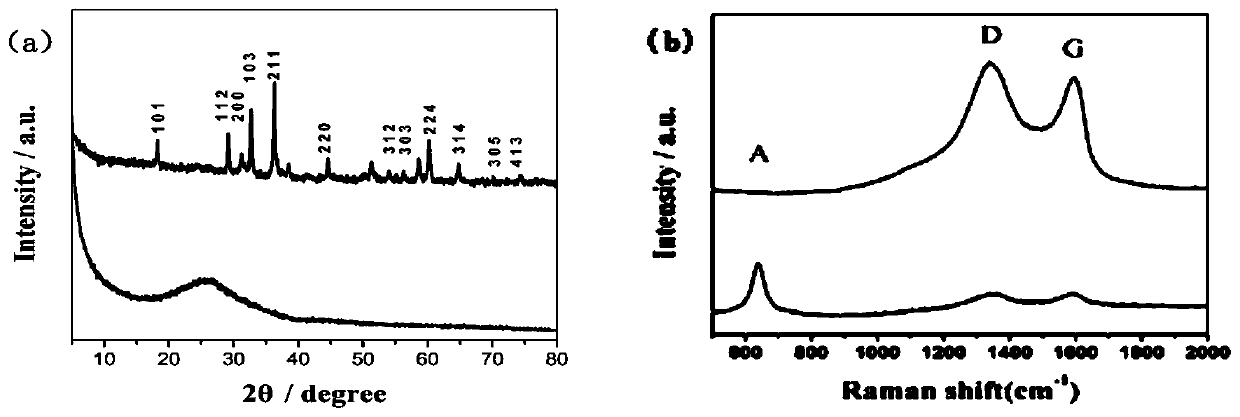

Image

Examples

Embodiment 1

[0043] A kind of preparation method of graphene / manganese dioxide supercapacitor electrode, comprises the steps:

[0044] Step 1, mix:

[0045] (1) First weigh 2g of manganese sulfate (MnSO 4 ), 2g phosphorus pentoxide (P 2 o 5 ), 2g ferric chloride (FeCl 3 ), 1g sodium nitrate (NaNO 3 ) obtain mixture with 2g graphite, and seal up in dry box; Described graphite is 250 order graphite flakes;

[0046] (2) in the magnetic stirring water bath, will contain 20g mass fraction and be 95% concentrated sulfuric acid (H 2 SO 4 ) in a three-necked flask heated to 70°C, then slowly add the medicines weighed in the step (1) into the concentrated sulfuric acid successively, carry out magnetic stirring and the reaction time is 20min, and obtain the pre-oxidized graphite suspension;

[0047] (3) Move the pre-oxidized graphite suspension, that is, the three-necked flask filled with the reactants to the ice-water bath prepared in advance, and wait for the reaction solution to be cooled ...

Embodiment 2

[0055] A kind of preparation method of graphene / manganese dioxide supercapacitor electrode, comprises the steps:

[0056] Step 1, mix:

[0057] (1) First weigh 2g of manganese sulfate (MnSO 4 ), 2g phosphorus pentoxide (P 2 o 5 ), 2g ferric chloride (FeCl 3 ), 1g sodium nitrate (NaNO 3 ) is mixed with 2g graphite to obtain the mixture, and sealed in a dry box; the graphite is 200 mesh flake graphite;

[0058] (2) in the magnetic stirring water bath, will contain 20g mass fraction and be 96% concentrated sulfuric acid (H 2 SO 4 ) in a three-necked flask heated to 75°C, then slowly add the medicines weighed in the step (1) into concentrated sulfuric acid successively, and carry out magnetic stirring for 25 minutes to obtain a pre-oxidized graphite suspension;

[0059] (3) Move the pre-oxidized graphite suspension, that is, the three-necked flask filled with reactants to a pre-prepared ice-water bath, and wait for the reaction solution to be cooled to 8 ° C. Under stirring...

Embodiment 3

[0068] A kind of preparation method of graphene / manganese dioxide supercapacitor electrode, comprises the steps:

[0069] Step 1, mix:

[0070] (1) First weigh 2g of manganese sulfate (MnSO 4 ), 2g phosphorus pentoxide (P 2 o 5 ), 2g ferric chloride (FeCl 3 ), 1g sodium nitrate (NaNO 3 ) obtain mixture with 2g graphite, and seal up in dry box; Described graphite is 300 order graphite flakes;

[0071] (2) in the magnetic stirring water bath, will contain 20g mass fraction and be 97% concentrated sulfuric acid (H 2 SO 4 ) in a three-necked flask heated to 90°C, then slowly add the medicines weighed in the step (1) into the concentrated sulfuric acid successively, carry out magnetic stirring and the reaction time is 60min, and obtain the pre-oxidized graphite suspension;

[0072] (3) Move the pre-oxidized graphite suspension, that is, the three-necked flask containing the reactants to the ice-water bath prepared in advance, and wait for the reaction solution to cool to 7°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com