Nickel-tin alloy-based three-dimensional tin oxide nanoparticle-micron porous nickel-tin compound lithium ion battery anode and preparation method thereof

A lithium-ion battery and nanoparticle technology, which is applied in nanotechnology for materials and surface science, battery electrodes, active material electrodes, etc., can solve the problems of large irreversible capacity, low reversible specific capacity, shedding, etc., and achieve multi-embedded Lithium active sites, increased specific surface area, full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, a method for preparing a negative electrode of a nickel-tin alloy-based three-dimensional tin oxide nanoparticle-microporous nickel-tin compound lithium ion battery is provided, and the specific steps are as follows:

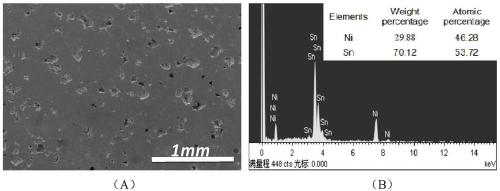

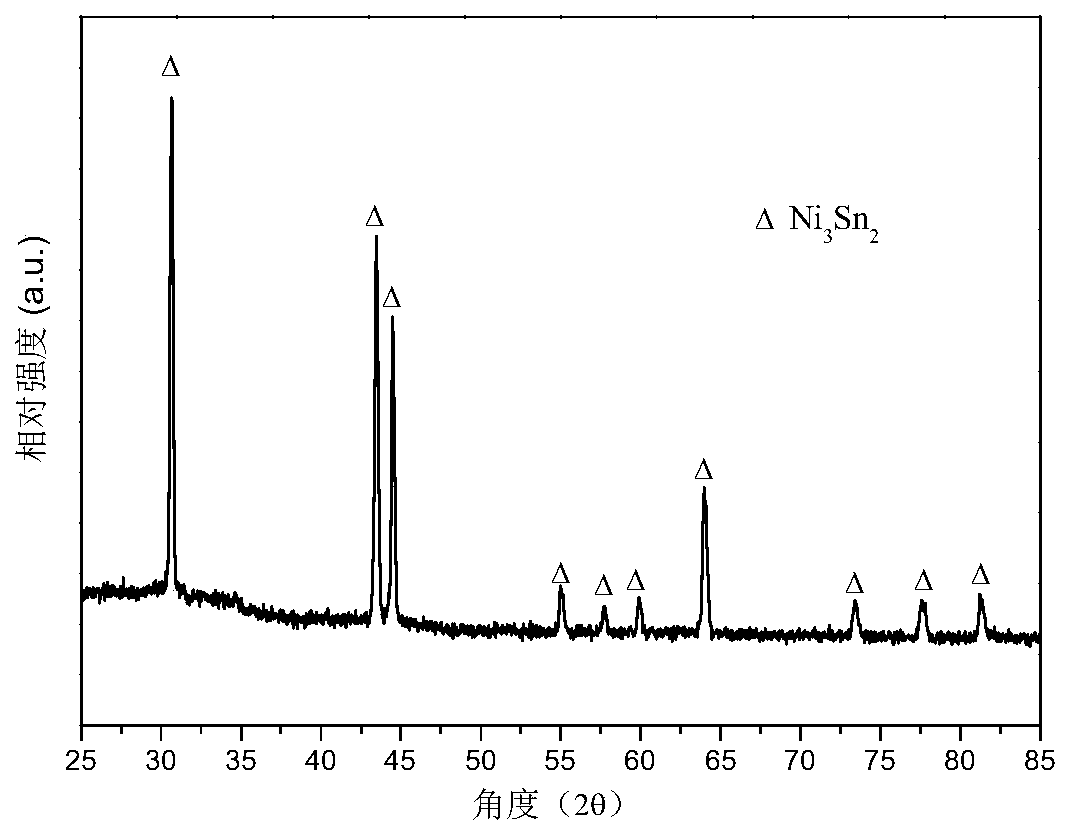

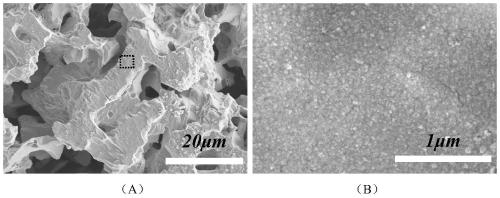

[0043] (1) Weigh the tin block and the nickel block according to the ratio of the atomic percentage of tin to nickel being 55:45, and melt them in a muffle furnace to obtain a nickel-tin alloy ingot. Cut the nickel-tin alloy ingot into nickel-tin alloy sheets with a thickness of 650 μm with a wire cutting machine, and then use 280 mesh, 800 mesh, 1200 mesh, and 2000 mesh water sandpaper to polish the surface of the nickel-tin alloy sheet, and then use a particle size of 0.5 μm diamond polishing paste for polishing, the polished nickel-tin alloy sheet is cleaned with deionized water and then dried. Scanning electron micrographs of nickel-tin alloy flakes are as follows: figure 1 As shown in the (A) figure, the EDS spectrum of the nicke...

Embodiment 2

[0053] In this embodiment, a method for preparing a negative electrode of a three-dimensional tin oxide nanoparticle-microporous nickel-tin compound lithium-ion battery is provided, and the specific steps are as follows:

[0054] (1) Weigh the tin block and the nickel block according to the ratio of the atomic percentage of tin to nickel being 55:45, and melt them in a muffle furnace to obtain a nickel-tin alloy ingot. Cut the nickel-tin alloy ingot into nickel-tin alloy sheets with a thickness of 650 μm with a wire cutting machine, and then use 280 mesh, 800 mesh, 1200 mesh, and 2000 mesh water sandpaper to polish the surface of the nickel-tin alloy sheet, and then use a particle size of 0.5 μm diamond polishing paste for polishing, the polished nickel-tin alloy sheet is cleaned with deionized water and then dried. Scanning electron micrographs of nickel-tin alloy flakes are as follows: figure 1 As shown in the (A) figure, the EDS spectrum of the nickel-tin alloy sheet is as...

Embodiment 3

[0070] In this embodiment, a method for preparing a negative electrode of a nickel-tin alloy-based three-dimensional tin oxide nanoparticle-microporous nickel-tin compound lithium ion battery is provided, and the specific steps are as follows:

[0071](1) Weigh the tin block and the nickel block according to the ratio of the atomic percentage of tin to nickel being 65:35, and melt them in a muffle furnace to obtain a nickel-tin alloy ingot. Cut the nickel-tin alloy ingot into nickel-tin alloy sheets with a thickness of 450 μm with a wire cutting machine, and then use 280 mesh, 800 mesh, 1200 mesh, and 2000 mesh water sandpaper to polish the surface of the nickel-tin alloy sheet, and then use a particle size of 0.5 μm diamond polishing paste for polishing, the polished nickel-tin alloy sheet is cleaned with deionized water and then dried. Scanning electron micrographs of nickel-tin alloy flakes are as follows: Figure 11 As shown in the (A) figure, the EDS spectrum of the nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com