Microwave absorbing material and preparation method thereof

A wave-absorbing material and composite material technology, applied in the field of wave-absorbing materials, can solve problems such as unsatisfactory, nanopore disappearance, network collapse, etc., to improve mechanical properties and heat resistance, prevent oxidation and agglomeration, and facilitate processing and molding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

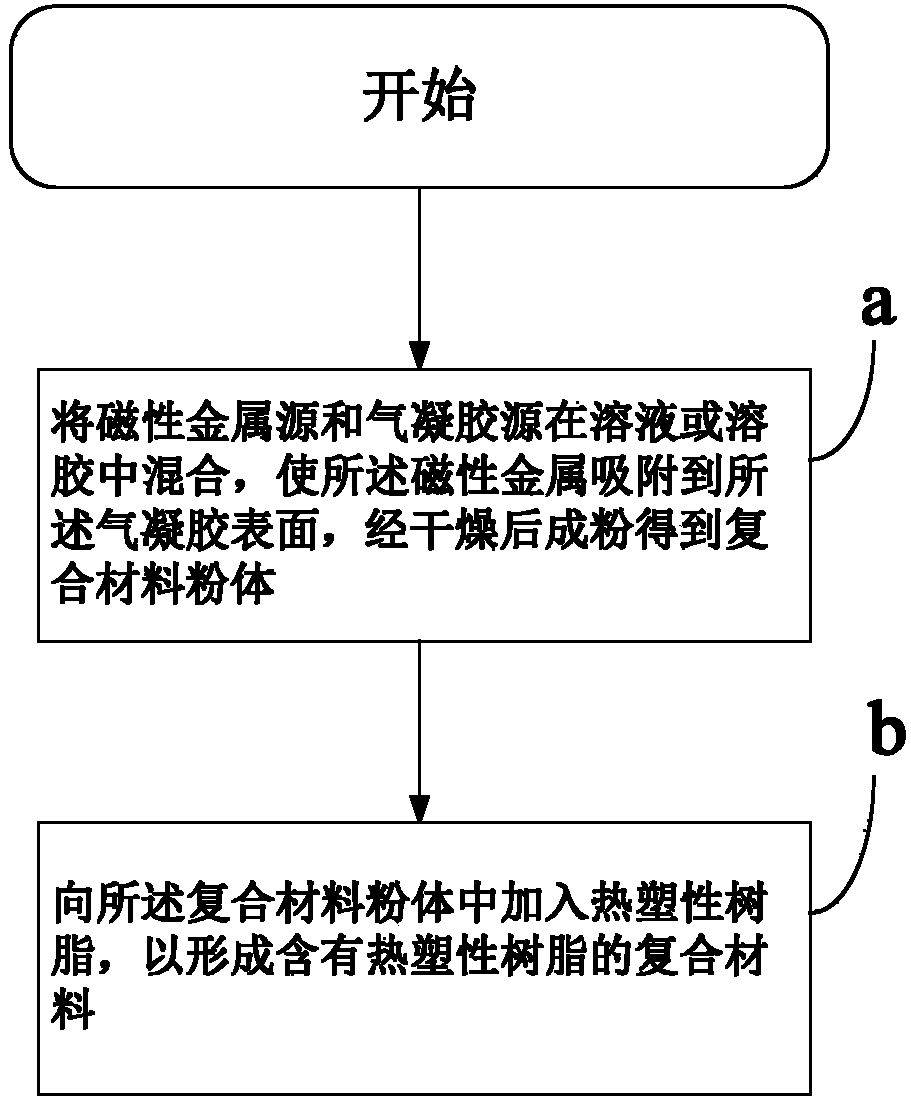

[0063] Other embodiments of the present invention relate to a method for preparing a wave-absorbing material, the method comprising the following steps:

[0064] Step a. Adsorbing the magnetic metal onto the surface of the airgel to obtain a composite material powder;

[0065] Step b. adding thermoplastic resin to the composite material powder to form a composite material containing thermoplastic resin;

[0066] Wherein the volume percentage of the thermoplastic resin is 5-90%, the volume percentage of the airgel is 0.1-90%, and the volume percentage of the magnetic metal is 0.1-50%.

[0067] Such as figure 1 As shown, in some embodiments, step a includes: adding the magnetic metal source to the sol formed by the airgel source, or adding the airgel source to the solution containing the magnetic metal source, so that the magnetic metal is adsorbed to the Airgel surface.

[0068] In some preferred embodiments, in step a, use tetraethyl orthosilicate or water glass or silica s...

example 1

[0082]a. Using ethyl orthosilicate as the silicon source, take 104 grams of ethyl orthosilicate, 31.5 grams of water, 46 to 460 grams of ethanol, and 31 to 310 grams of ethylene glycol, mix well, and the molar ratio is equivalent to that of ethyl orthosilicate Ester: water: ethanol is 1:3.5:4~20, obtains silica sol; Add the ammonia water that concentration is 0.35mol / L dropwise, adjust pH value to 2.5~3.5, stand still, obtain silica gel, Aging; then use the method of supercritical drying, put the composite wet gel in a high-temperature and high-pressure reactor, evacuate it with argon, adjust the argon pressure at 12MPa, control the temperature at 150°C, supercritical reaction for 10h, and argon protection The atmosphere dropped to room temperature, took it out, and obtained a density of 0.13g / cm 3 , the specific surface area is 860m 2 / g of silica airgel powder.

[0083] b. Get 15.6g of nano-carbonyl iron powder and place it in 500ml of ethanol-acetone solution, add 0.26g o...

example 2

[0087] a. Using ethyl orthosilicate as the silicon source, take 104 grams of ethyl orthosilicate, 31.5 grams of water, 92 to 460 grams of ethanol, and 31 to 310 grams of ethylene glycol, mix well, and the molar ratio is equivalent to that of ethyl orthosilicate Ester: water: ethanol: ethylene glycol is 1:3.5:4~20:1~10 to obtain a silica sol; gradually add 15.6 grams of nano-carbonyl iron powder to the sol, and stir evenly.

[0088] b. Add ammonia water with a concentration of 0.35 mol / L dropwise to the mixed solution obtained in step a, adjust the pH value to 2.5-3.5, and let it stand to age the ferrosilicon dioxide composite sol to form a gel.

[0089] c. Use acetone as a replacement agent to remove the water in the gel; then use acetone medium to add the gel, and then add 1% to 5% of the volume of the gel to disperse the sodium dodecylbenzenesulfonate dispersant to prevent Airgel nanopowders are agglomerated and then mixed by ball milling.

[0090] d. Use the method of norm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com