Combined foaming polylactic acid heat-resistant flame-retardant modified material and preparation method of product

A technology for foaming polylactic acid and modified materials, which is applied in the field of preparation of combined foamed polylactic acid heat-resistant and flame-retardant modified materials and products, can solve the problems of high cost of polylactic acid, poor thermal stability and the like, and achieves high cost improvement. , The effect of improving flame retardant performance and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

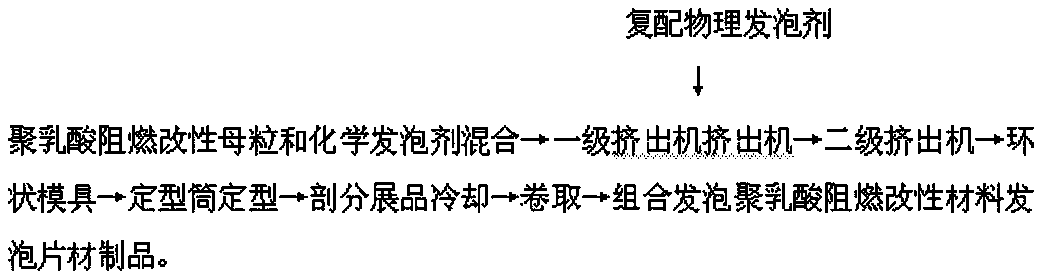

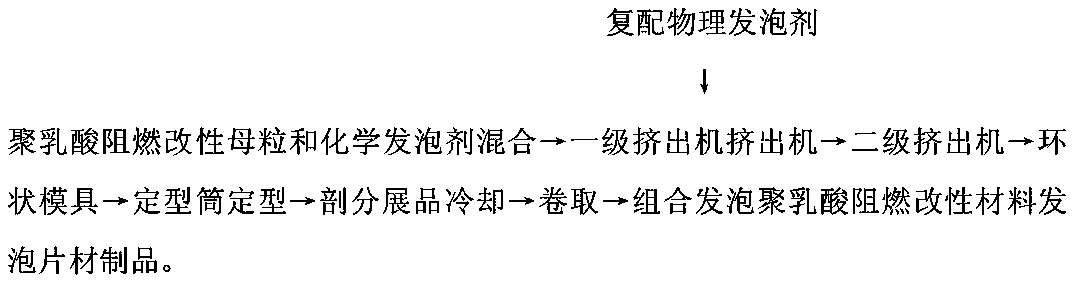

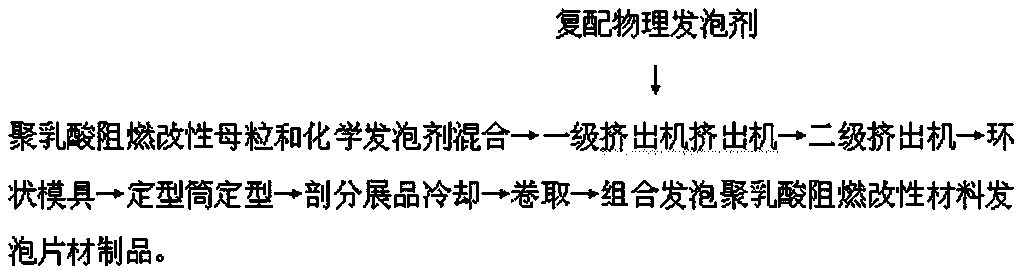

[0072] A method for preparing a combined foamed polylactic acid heat-resistant and flame-retardant modified material and product, comprising the following steps:

[0073] (1) Weigh 5 parts of polycaprolactone, 95 parts of polylactic acid resin and 1.5 parts of epoxy-functionalized ADR chain extender from BASF, Germany, and dry them at 60°C for 7 hours;

[0074] (2) The raw materials of step (1) and 8 parts of halloysite nanotube powder loaded with polyphosphoborosiloxane, 1 part of bis-tert-butylperoxycumene, oleic acid amide 0.5 parts, 0.5 parts of citrate, and 1.8 parts of calcium carbonate are mixed in a mixer, and the mixture is fed into a twin-screw extruder, wherein the temperature of each section of the twin-screw extruder is set to 130°C at the feed inlet, and the temperature of the other sections is sequentially 160°C, 175°C, 195°C, 210°C, 195°C, 170°C, screw length-to-diameter ratio 40, screw host speed 140rpm, realize reactive extrusion, and obtain polylactic acid f...

Embodiment 2

[0078] A method for preparing a combined foamed polylactic acid heat-resistant and flame-retardant modified material and product, comprising the following steps:

[0079] (1) Weigh 8 parts of starch, 92 parts of polylactic acid resin and 1.3 parts of epoxy-functionalized ADR chain extender from BASF, Germany, and dry them at 60°C for 7 hours;

[0080] (2) The raw materials of step (1) and 9 parts of halloysite nanotube powder loaded with polyphosphoborosiloxane, 1.5 parts of bis-tert-butylperoxycumene, erucamide 0.8 parts, 0.7 parts of glyceryl monostearate, 1.6 parts of talcum powder, and 0.4 parts of sorbitol nucleating agent are mixed in a mixer, and the mixture is added to a twin-screw extruder, wherein the temperature of each section of the twin-screw extruder is set The temperature of the feed inlet is 130°C, and the temperature of the other sections is 160°C, 175°C, 195°C, 210°C, 195°C, 170°C, the length-to-diameter ratio of the screw is 40, and the speed of the screw m...

Embodiment 3

[0084] A method for preparing a combined foamed polylactic acid heat-resistant and flame-retardant modified material and product, comprising the following steps:

[0085] (1) Weigh 10 parts of polyglycolic acid, 90 parts of polylactic acid resin and 1 part of BASF's epoxy-functional ADR chain extender by weight, and dry them at 60°C for 7 hours;

[0086] (2) Take the raw materials of step (1) and 10 parts by weight of halloysite nanotube powder loaded with polyphosphoborosiloxane, 2 parts of bis-tert-butylperoxycumene, stearic acid 1 part of amide, 0.9 part of pentaerythritol stearate, and 2.5 parts of sorbitol nucleating agent are mixed in a mixer, and the mixture is added to a twin-screw extruder, wherein the temperature of each section of the twin-screw extruder is set to The material inlet is 130°C, the temperature of the other sections is 160°C, 175°C, 195°C, 210°C, 195°C, 170°C in sequence, the length-to-diameter ratio of the screw is 40, and the speed of the screw main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com