Molybdenum carbide/carbon nano hydrogen production catalyst synthesized by utilizing ink

A catalyst and molybdenum carbide technology, which is applied in physical/chemical process catalysts, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as poor electrocatalytic conductivity, limited electrocatalytic hydrogen production capacity, difficulties, etc. Inexpensive, excellent electrocatalytic hydrogen production activity and stability, and the effect of promoting transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] At 80 °C, 1.87 g of didecyldimethylammonium bromide and 1.5 g of ink were dispersed in 50 mL of deionized water. Then, in the state of magnetic stirring, 30 g of ammonium molybdate solution with a mass concentration of 2.4% was added dropwise thereto, and reacted at 80° C. for 24 h. After the reaction, the hybrid precursor MoO was obtained by centrifugal drying. x / DDA / CI.

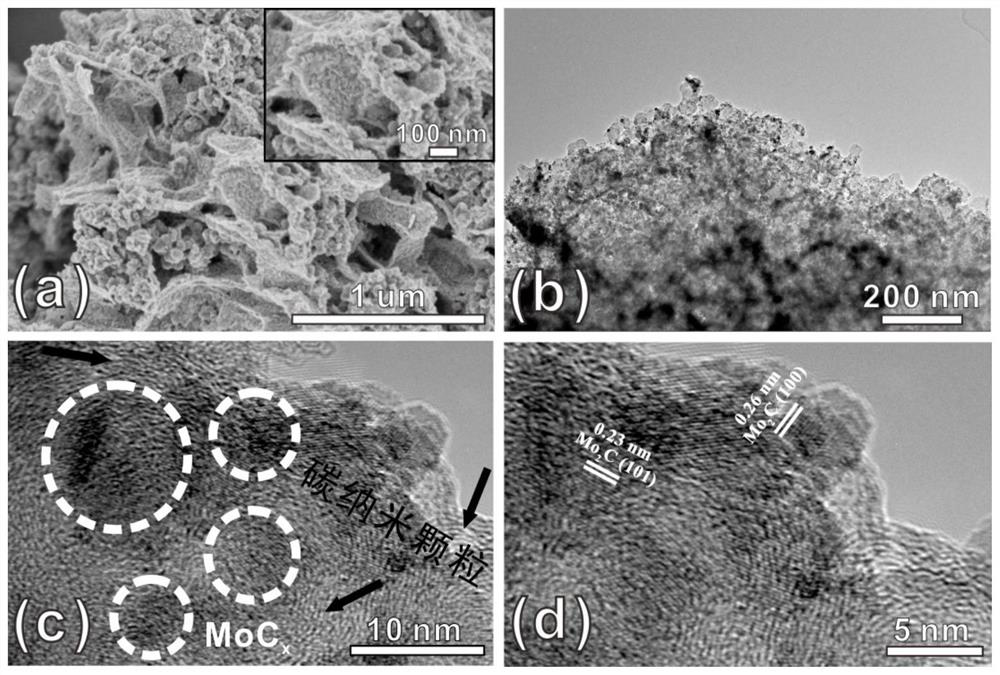

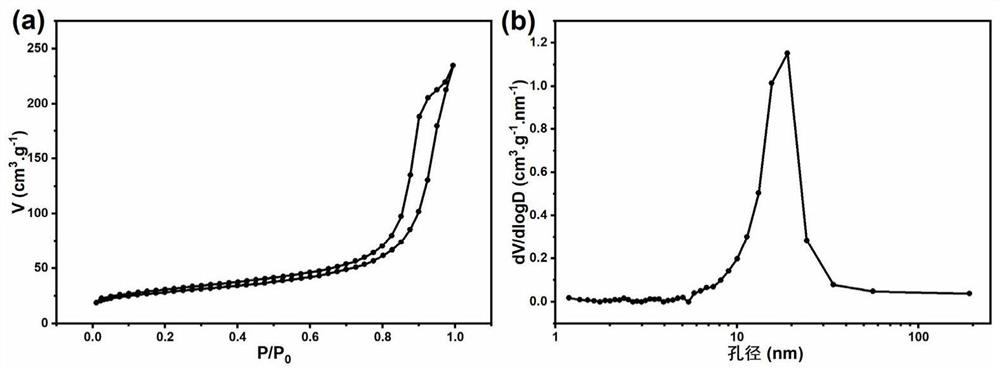

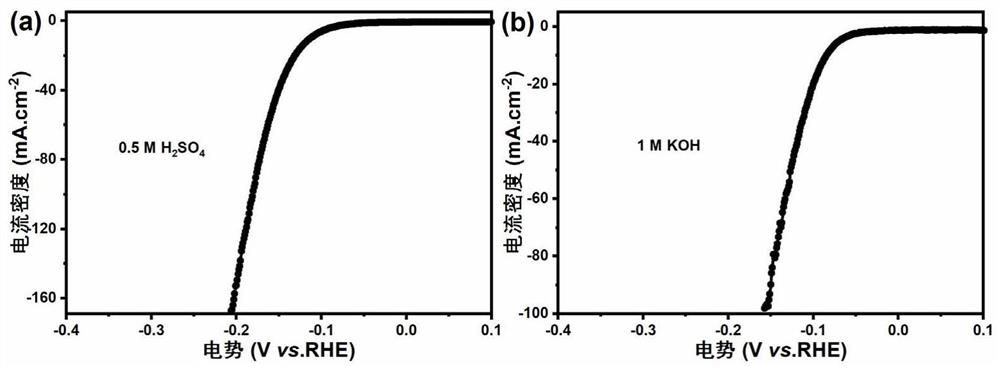

[0038] Put the above precursor in a tube furnace under the protection of argon atmosphere, raise the temperature to 750°C, keep the temperature constant for 5 hours, and control the heating rate at 5°C / min, you can get 3D hierarchical porous structure molybdenum carbide / carbon nanometer electrocatalytic hydrogen production catalyst. Such as figure 1 As shown: the catalyst as a whole presents a three-dimensional hierarchical porous structure, and its structure is composed of molybdenum carbide nanoparticles and carbon nanoparticles intersecting, and the particle size of the active center molybdenu...

Embodiment 2

[0044] At 80 °C, 1.87 g of didecyldimethylammonium bromide and 0 g of ink were dispersed in 50 mL of deionized water. Then, in the state of magnetic stirring, 30 g of ammonium molybdate solution with a mass concentration of 2.4% was added dropwise thereto, and reacted at 80° C. for 24 h. After the reaction, the hybrid precursor MoO was obtained by centrifugal drying. x / DDA / CI.

[0045] Put the above precursor in a tube furnace under the protection of argon atmosphere, raise the temperature to 750°C, keep the temperature constant for 5 hours, and control the heating rate at 5°C / min, you can get 3D hierarchical porous structure molybdenum carbide / carbon nanometer electrocatalytic hydrogen production catalyst.

[0046] The electrochemical test of the prepared 3D hierarchical porous structure molybdenum carbide / carbon nanometer electrocatalytic hydrogen production catalyst is the same as the steps (a) and (b) of the implementation case 1.

[0047] The catalyst exhibits high hy...

Embodiment 3

[0049] At 80 °C, 1.87 g of didecyldimethylammonium bromide and 0.5 g of ink were dispersed in 50 ml of deionized water. Then, in the state of magnetic stirring, 30 g of ammonium molybdate solution with a mass concentration of 2.4% was added dropwise thereto, and reacted at 80° C. for 24 h. After the reaction, the hybrid precursor MoO was obtained by centrifugal drying. x / DDA / CI.

[0050] Put the above precursor in a tube furnace under the protection of argon atmosphere, raise the temperature to 750°C, keep the temperature constant for 5 hours, and control the heating rate at 5°C / min, you can get 3D hierarchical porous structure molybdenum carbide / carbon nanometer electrocatalytic hydrogen production catalyst.

[0051] The electrochemical test of the prepared 3D hierarchical porous structure molybdenum carbide / carbon nanometer electrocatalytic hydrogen production catalyst is the same as the steps (a) and (b) of the implementation case 1.

[0052] The catalyst exhibits high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com