Nanostructure-containing polycrystalline diamond, polycrystalline diamond composite sheet and preparation method thereof

A polycrystalline diamond and nanostructure technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of lack of strong bonding, overcome the difficulties in the preparation process, improve the comprehensive mechanical properties of hardness and toughness, The effect of overcoming cleavage brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

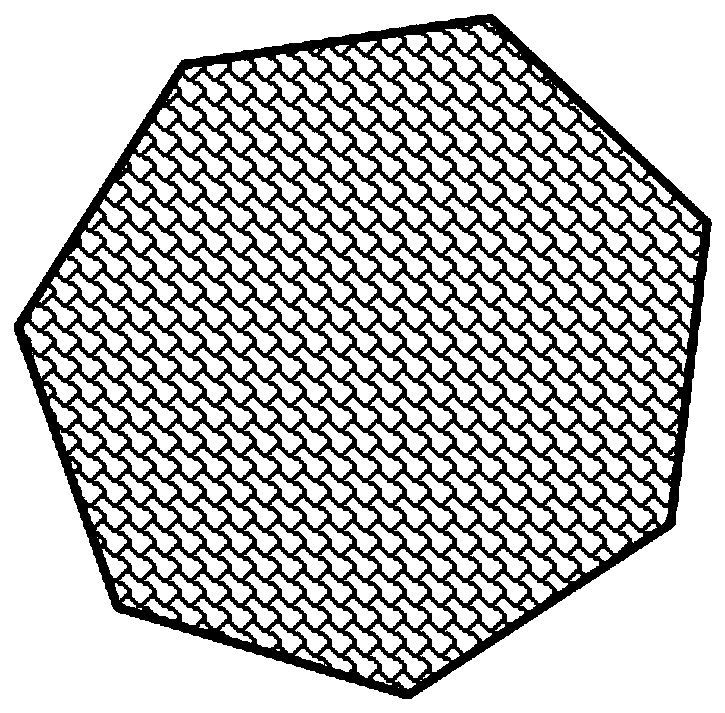

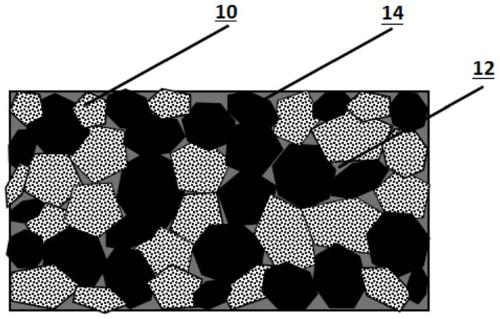

[0051] Embodiment 1: prepare the polycrystalline diamond containing nanostructure

[0052] Commercially available Kabuna polytype nanostructured polycrystalline diamond particles and micron-sized single crystal diamond particles are used as raw materials for the synthesis of polycrystalline diamond. The polycrystalline diamond particles of Kabuna multi-type nanostructure are synthesized by the explosive shock wave method, they contain 99.0%-99.5% (weight percentage) of diamond, and their nominal size is 10 microns, and they are in block shape. Micron-scale single crystal diamond particles are synthesized by static high temperature and high pressure method, they contain 99.5% (weight percent) of diamond, their nominal size is 10 microns, and they are block-shaped. The two diamond particles were mixed in a mass ratio of 1:1. These diamond particles are treated with high temperature alkali and acid solution to further remove impurities. High-temperature alkali solution treatmen...

Embodiment 2

[0053] Example 2: Preparation of polycrystalline diamond composite sheets containing nanostructures

[0054] Commercially available Kabuna polytype nanostructured polycrystalline diamond particles and micron-sized single crystal diamond particles are used as raw materials for the synthesis of polycrystalline diamond. The polycrystalline diamond particles of Kabuna multi-type nanostructure are synthesized by the explosive shock wave method, they contain 99.0%-99.5% (weight percentage) of diamond, and their nominal size is 10 microns, and they are in block shape. Micron-scale single crystal diamond particles are synthesized by static high temperature and high pressure method, they contain 99.5% (weight percent) of diamond, their nominal size is 10 microns, and they are block-shaped. These diamond particles are treated with high temperature alkali and acid solution to further remove impurities. High-temperature alkali solution treatment is to mix diamond particles and sodium hyd...

Embodiment 3

[0056] Example 3: Preparation of thermally stable polycrystalline diamond containing nanostructures and thermally stable polycrystalline diamond composite sheets containing nanostructures

[0057] In this example, the samples used in the test are the polycrystalline diamond containing nanostructure in Example 1 and the polycrystalline diamond composite sheet containing nanostructure in Example 2. Remove metal binder-cobalt with mixed acid, the volume composition of mixed acid is: 25% nitric acid (concentration is 95wt.%) and 75% hydrochloric acid (concentration is 36wt.%), and the depth of cobalt removal is about 0.2 mm, prepared respectively Thermally stable polycrystalline diamond containing nanostructures and thermally stable polycrystalline diamond composite sheets containing nanostructures are produced.

[0058] In the present invention, the preparation method of polycrystalline diamond containing nanostructure and polycrystalline diamond composite sheet is similar to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com