Preparation method for lithium ion battery composite cathode material

A technology for lithium-ion batteries and negative electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of reducing material structure stability, cycle stability, and ineffective effects, and achieves easy control of particle size and high The effect of specific capacity and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

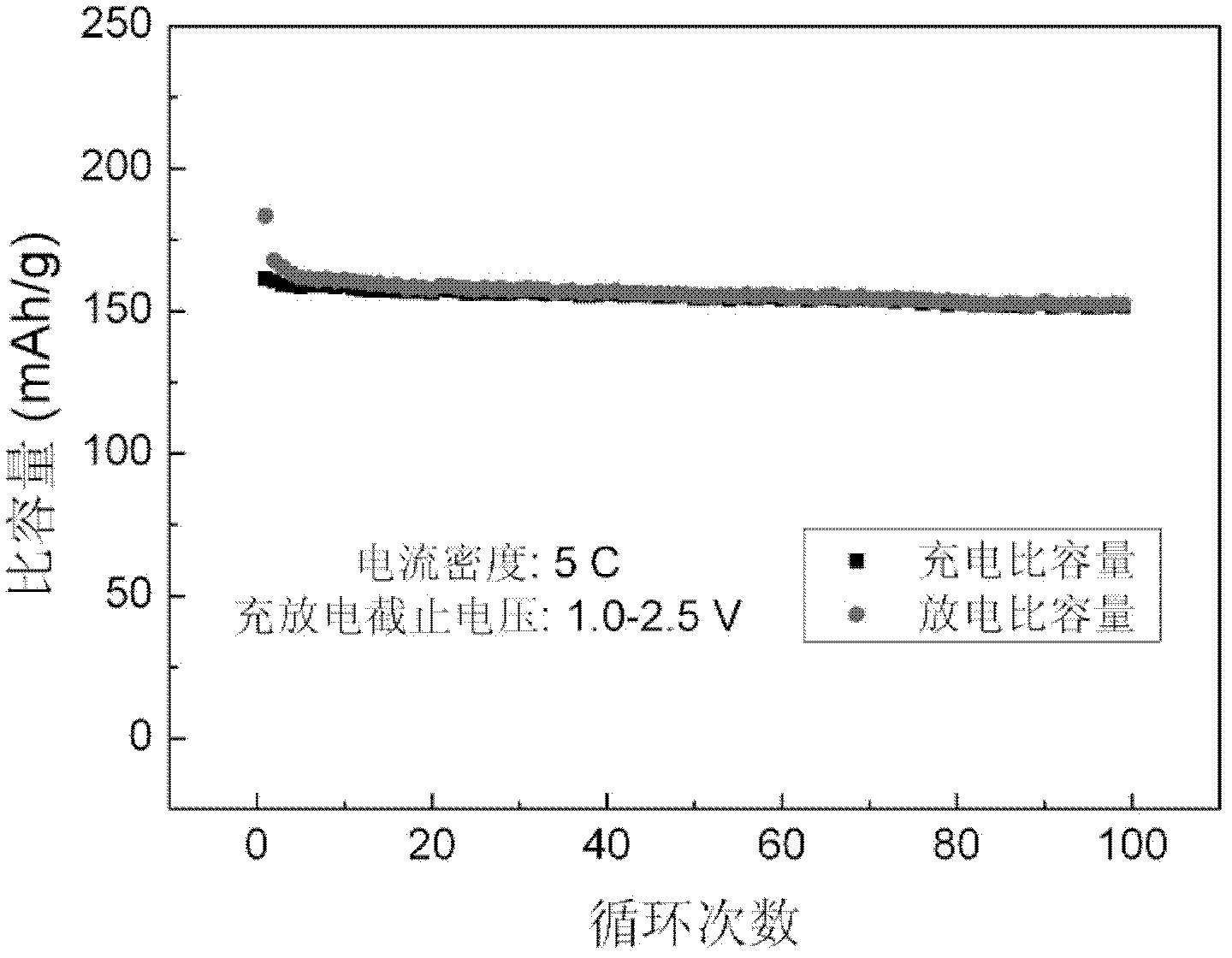

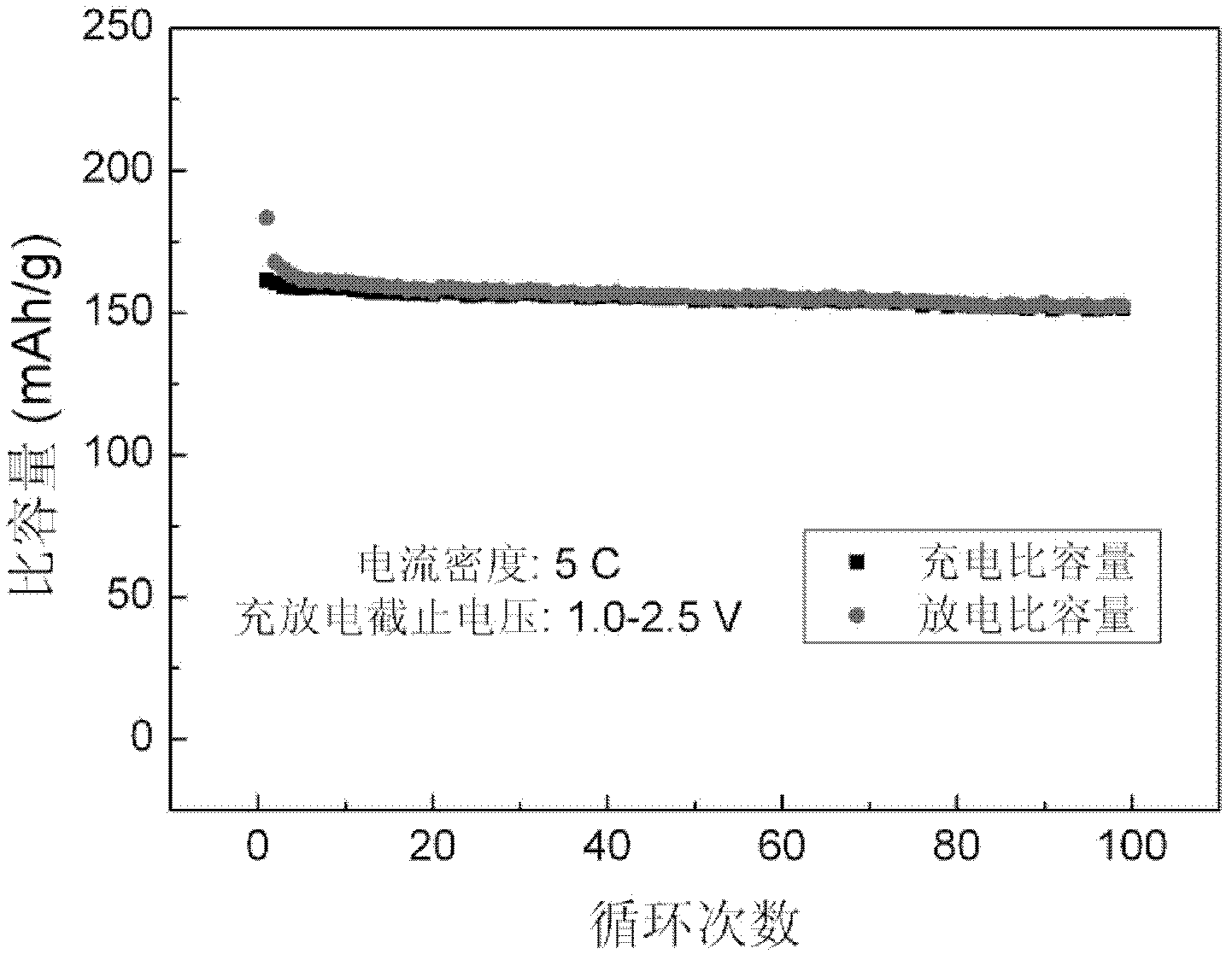

Embodiment 1

[0038] Weigh 2.383 g of analytically pure tetrabutyl titanate (purity ≥ 99.0%) and dissolve it in 50 ml of absolute ethanol, stir well to make a clear and transparent solution; according to the atomic ratio Li / Ti = 1.4, weigh 1.000 g of lithium acetate (purity ≥ 99.0%), add to the clear solution, continue to stir until a uniform solution is formed; add 2 ml of ammonia water to the solution drop by drop, mix well, transfer the mixture to a 100 ml autoclave, and place in an oven, 180 o C was incubated for 24 hours, cooled to room temperature, and the resulting product was washed with absolute ethanol, filtered, and placed in an oven for 80 o C dried to obtain Li 4 Ti 5 o 12 -TiO 2 Precursor; under air atmosphere, the resulting precursor is heated to 600 o C was kept for 2 hours, and then cooled to room temperature with the furnace to prepare Li 4 Ti 5 o 12 -TiO 2 Powder, among them, TiO 2 in Li 4 Ti 5 o 12 -TiO 2 The content in the powder is about 23%; weigh 0.450 ...

Embodiment 2

[0042] Weigh 2.383 g of analytically pure tetrabutyl titanate (purity ≥ 99.0%) and dissolve it in 50 ml of absolute ethanol, stir well to make a clear and transparent solution; according to the atomic ratio Li / Ti = 1.4, weigh 1.000 g of lithium acetate (purity ≥ 99.0%), add to the clear solution, continue to stir until a uniform solution is formed; add 1 ml of ammonia water to the solution drop by drop, mix well, transfer the mixture to a 100 ml autoclave, and place in an oven, 180 o C was incubated for 24 hours, cooled to room temperature, and the resulting product was washed with absolute ethanol, filtered, and placed in an oven for 80 o C dried to obtain Li 4 Ti 5 o 12 -TiO 2 Precursor; under air atmosphere, the resulting precursor is heated to 600 o C was kept for 2 hours, and then cooled to room temperature with the furnace to prepare Li 4 Ti 5 o 12 -TiO 2 Powder, among them, TiO 2 in Li 4 Ti 5 o 12 -TiO 2 The content in the powder is about 19%; weigh 0.450 ...

Embodiment 3

[0046] Weigh 2.383 g of analytically pure tetrabutyl titanate (purity ≥ 99.0%) and dissolve it in 50 ml of absolute ethanol, stir well to make a clear and transparent solution; according to the atomic ratio Li / Ti = 1.2, weigh 0.857 g of lithium acetate (purity ≥ 99.0%), add to the clear solution, continue to stir until a uniform solution is formed; add 2 ml of ammonia water to the solution drop by drop, mix well, transfer the mixture to a 100 ml autoclave, and place in an oven, 180 o C was incubated for 24 hours, cooled to room temperature, and the resulting product was washed with absolute ethanol, filtered, and placed in an oven for 80 o C dried to obtain Li 4 Ti 5 o 12 -TiO 2 Precursor; under air atmosphere, the resulting precursor is heated to 600 o C was kept for 2 hours, and then cooled to room temperature with the furnace to prepare Li 4 Ti 5 o 12 -TiO 2 Powder, among them, TiO 2 in Li 4 Ti 5 o 12 -TiO 2 The content in the powder is about 25%; weigh 0.450 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse specific capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com