Super-hydrophobic solid electrolyte of lithium-air battery and preparation method thereof

A solid-state electrolyte and lithium-air battery technology, which is applied in electrolytes, secondary batteries, fuel cell half-cells and secondary battery-type half-cells, can solve the problems of poor rate performance, low ionic conductivity of solid electrolytes, battery Short cycle time and other issues, to achieve the effect of good high temperature resistance, good ionic conductivity, excellent hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

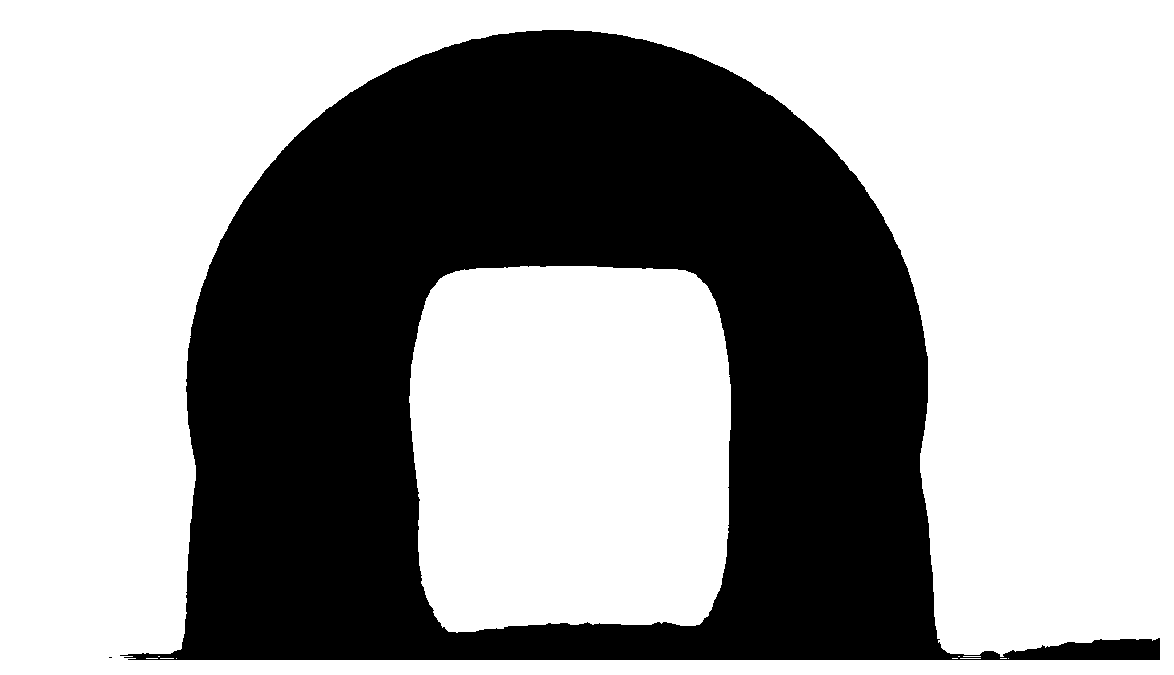

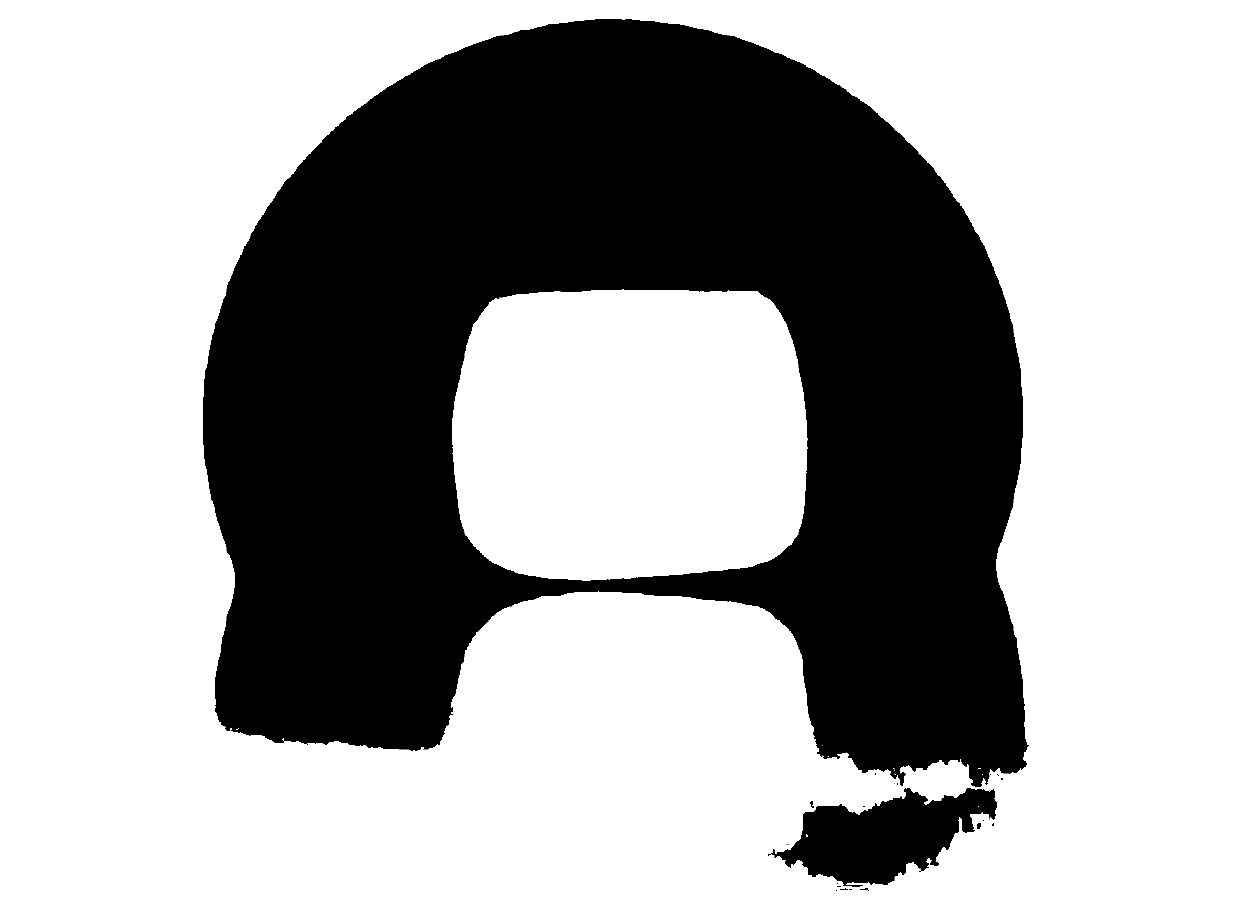

[0022] The preparation method of described superhydrophobic electrolyte comprises the following steps:

[0023] (1) After mixing nano-cobalt oxide, trifluoroethanesulfonic acid and PVA aqueous solution, add heptane as a solvent to heat, stir and dissolve to obtain a superhydrophobic pretreatment solution. Wherein, the weight proportion among nano cobalt oxide, trifluoroethanesulfonic acid, PVA aqueous solution and heptane is 1:3-5:7-9:8-10, and the mass fraction of PVA aqueous solution is 5%.

[0024] (2) After mixing the polymer matrix, lithium salt and ion-conducting material, add acetone as a solvent and stir in vacuum with a vacuum degree of -0.1MPa. After the slurry is obtained, pour it into a mold for heating and drying to obtain a solid electrolyte. Wherein, by weight, the polymer matrix content is 70%-80%, the lithium salt content is 10%-20%, and the ion-conducting inorganic material content is 10%-20%.

[0025] (3) Spraying the solution obtained in step (1) onto the ...

Embodiment 1

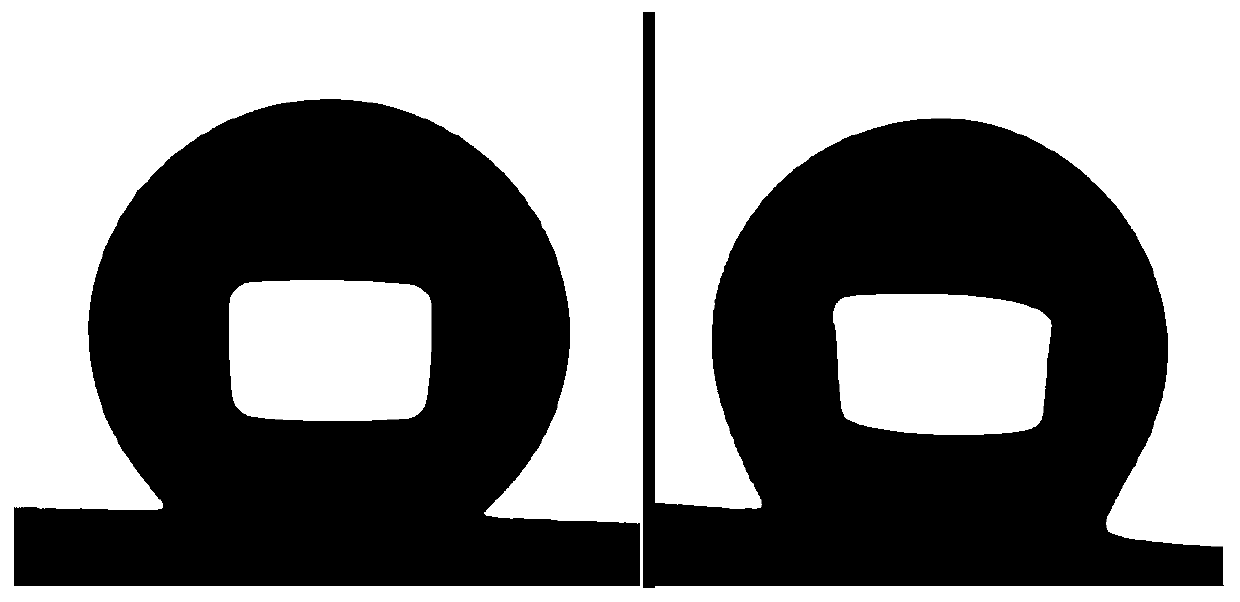

[0028] (1) After mixing nano-cobalt oxide, trifluoroethanesulfonic acid and PVA aqueous solution, heptane was added as a solvent and heated and stirred at 40° C. to dissolve to obtain a super-hydrophobic pretreatment solution. Wherein, the weight proportion among nano-cobalt oxide, trifluoroethanesulfonic acid, PVA aqueous solution and heptane is 1:3:7:8, and the mass fraction of PVA aqueous solution is 5%.

[0029] (2) After mixing the polymer matrix, lithium salt and ion-conducting material, add acetone as a solvent and stir in vacuum with a vacuum degree of -0.1MPa. After the slurry is obtained, pour it into a mold and heat it at 80°C until the solvent is completely evaporated. Dry under vacuum for 3 hours to obtain a solid electrolyte. Wherein, by weight, the polymer matrix content is 70%, the lithium salt content is 10%, and the ion-conducting inorganic material content is 20%.

[0030] (3) Spray the solution obtained in step (1) onto the surface of the solid electrolyte...

Embodiment 2

[0033] (1) After mixing nano-cobalt oxide, trifluoroethanesulfonic acid and PVA aqueous solution, heptane was added as a solvent and heated and stirred at 50° C. to dissolve to obtain a super-hydrophobic pretreatment solution. Wherein, the weight proportion among nano cobalt oxide, trifluoroethanesulfonic acid, PVA aqueous solution and heptane is 1:4:8:9, and the mass fraction of PVA aqueous solution is 5%.

[0034] (2) After mixing the polymer matrix, lithium salt and ion-conducting material, add acetone as a solvent and stir in vacuum with a vacuum degree of -0.1MPa. After the slurry is obtained, pour it into a mold and heat it at 80°C until the solvent is completely evaporated. Dry under vacuum for 3 hours to obtain a solid electrolyte. Wherein, by weight, the polymer matrix content is 70%, the lithium salt content is 15%, and the ion-conducting inorganic material content is 15%.

[0035] (3) Spray the solution obtained in step (1) onto the surface of the solid electrolyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Water droplet contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com