Bismuth-doped argyrodite type sulfide solid electrolyte and preparation method thereof

A solid-state electrolyte, silver-sulfur germanium ore technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of long-term stability and cyclability being difficult to guarantee, restricting lithium-sulfur solid electrolytes, and poor chemical stability. Achieve good ionic conductivity, solve the effects of poor lithium metal stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

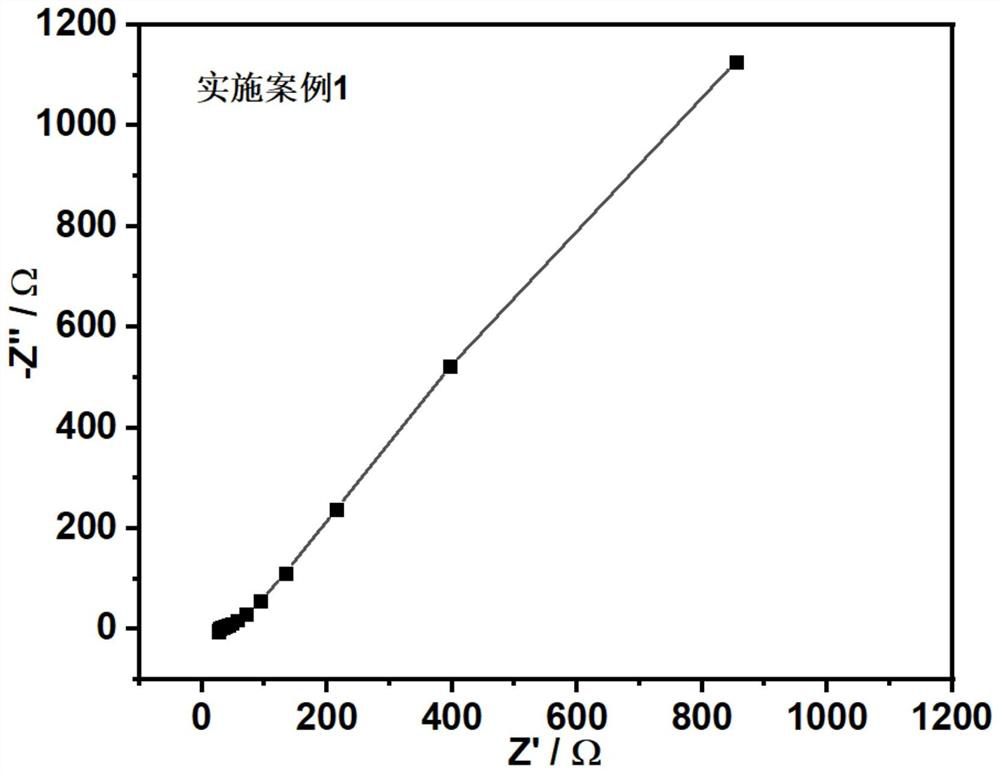

Embodiment 1

[0034] The present embodiment provides a method for preparing a bismuth-doped arginite-type solid electrolyte, which specifically includes the following steps:

[0035] Step 1. Put Li 2 S.P 2 S 5 , Bi 2 S 3 , LiCl according to the molar ratio of 2.55:0.475:0.025:1 in an argon atmosphere to grind and mix to obtain mixed powder. Sealed in a ball mill jar;

[0036] Step 2. Use a ball mill to mill the mixed powder. The rotating speed of the ball mill is 400rpm, and the ball milling time is 24 hours;

[0037] Step 3, compressing the above mixed powder into a tablet and packing it into a closed container, vacuuming and packaging;

[0038] Step 4. Heating to 550°C for solid-phase reaction for 8 hours;

[0039] Step 5. After the reaction is finished, it is naturally cooled to room temperature to obtain the composition of Li 6.1 Bi 0.05 P 0.95 S 5 Cl-doped bismuth-silver-germanite-type solid-state electrolyte material.

[0040] Step 6. Press the solid electrolyte powder ob...

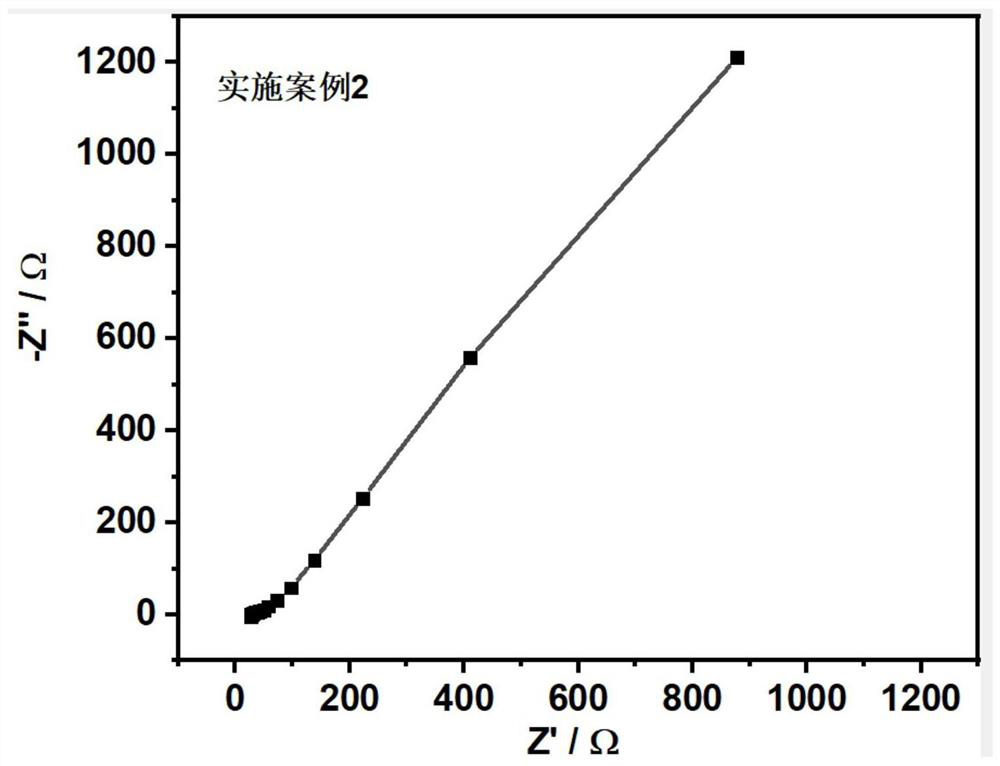

Embodiment 2

[0042] The present embodiment provides a method for preparing a bismuth-doped arginite-type solid electrolyte, which specifically includes the following steps:

[0043] Step 1. Put Li 2 S.P 2 S 5 , Bi 2 S 3 , LiCl according to the molar ratio of 2.6:0.45:0.05:1 in an argon atmosphere to grind and mix to obtain mixed powder. Sealed in a ball mill jar;

[0044] Step 2. Use a ball mill to mill the mixed powder. The rotating speed of the ball mill is 400rpm, and the ball milling time is 24 hours;

[0045] Step 3, compressing the above mixed powder into a tablet and packing it into a closed container, vacuuming and packaging;

[0046] Step 4. Heating to 550°C for solid-phase reaction for 8 hours;

[0047] Step 5. After the reaction is finished, it is naturally cooled to room temperature to obtain the composition of Li 6.2 Bi 0.1 P 0.9 S 5 Cl-doped bismuth-silver-germanite-type solid-state electrolyte material.

[0048] Step 6. Press the solid electrolyte powder obtaine...

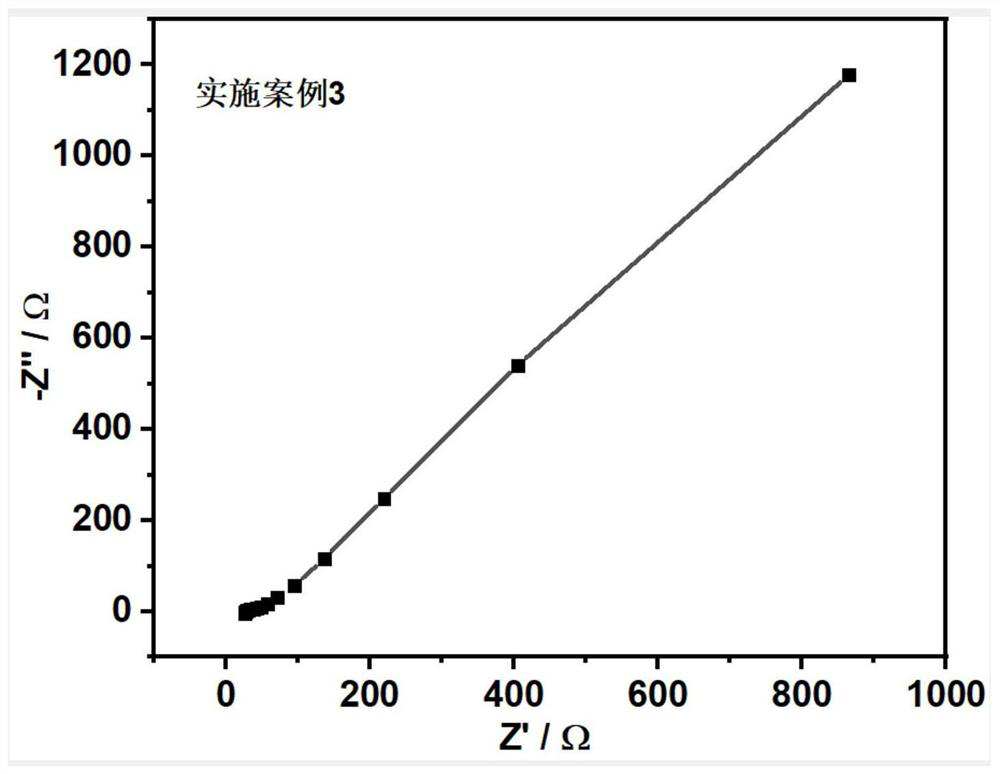

Embodiment 3

[0050] The present embodiment provides a method for preparing a bismuth-doped arginite-type solid electrolyte, which specifically includes the following steps:

[0051] Step 1. Put Li 2 S.P 2 S 5 , Bi 2 S 3 , LiCl according to the molar ratio of 2.65:0.425:0.075:1 in an argon atmosphere to grind and mix to obtain a mixed powder. Sealed in a ball mill jar;

[0052] Step 2. Use a ball mill to mill the mixed powder. The rotating speed of the ball mill is 400rpm, and the ball milling time is 24 hours;

[0053] Step 3, compressing the above mixed powder into a tablet and packing it into a closed container, vacuuming and packaging;

[0054] Step 4. Heating to 550°C for solid-phase reaction for 8 hours;

[0055] Step 5. After the reaction is finished, it is naturally cooled to room temperature to obtain the composition of Li 6.3 Bi 0.15 P 0.85 S 5 Cl-doped bismuth-silver-germanite-type solid-state electrolyte material.

[0056] Step 6. Press the solid electrolyte powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com