Glass composition for absorbing ultraviolet ray and infrared ray and its application

A glass composition and ultraviolet technology, applied in windshields, transportation and packaging, windows, etc., can solve the problems of reducing near-infrared transmittance, prone to flaws on the glass surface, affecting visible light transmittance, etc., to reduce the temperature , Excellent heat insulation effect, stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

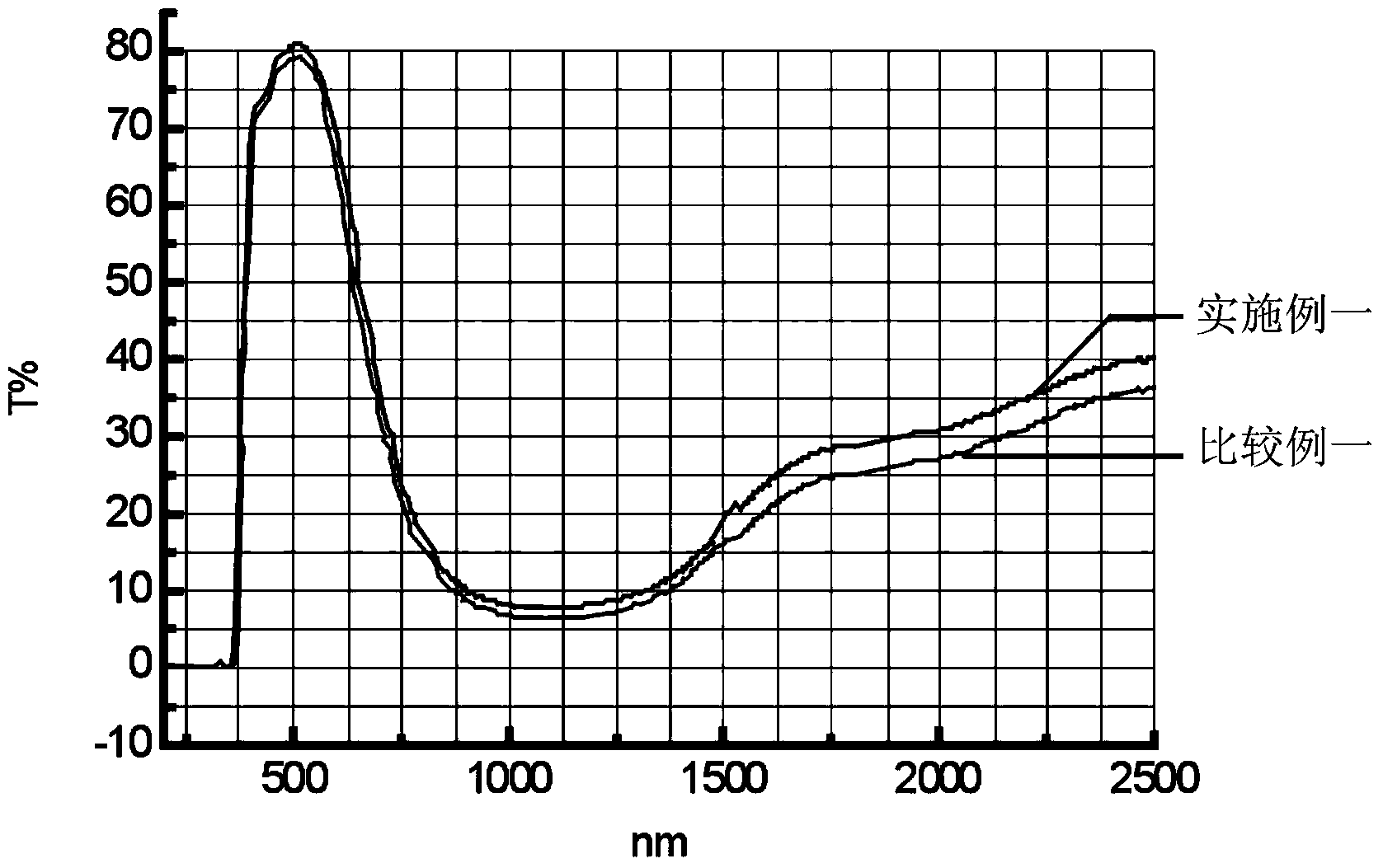

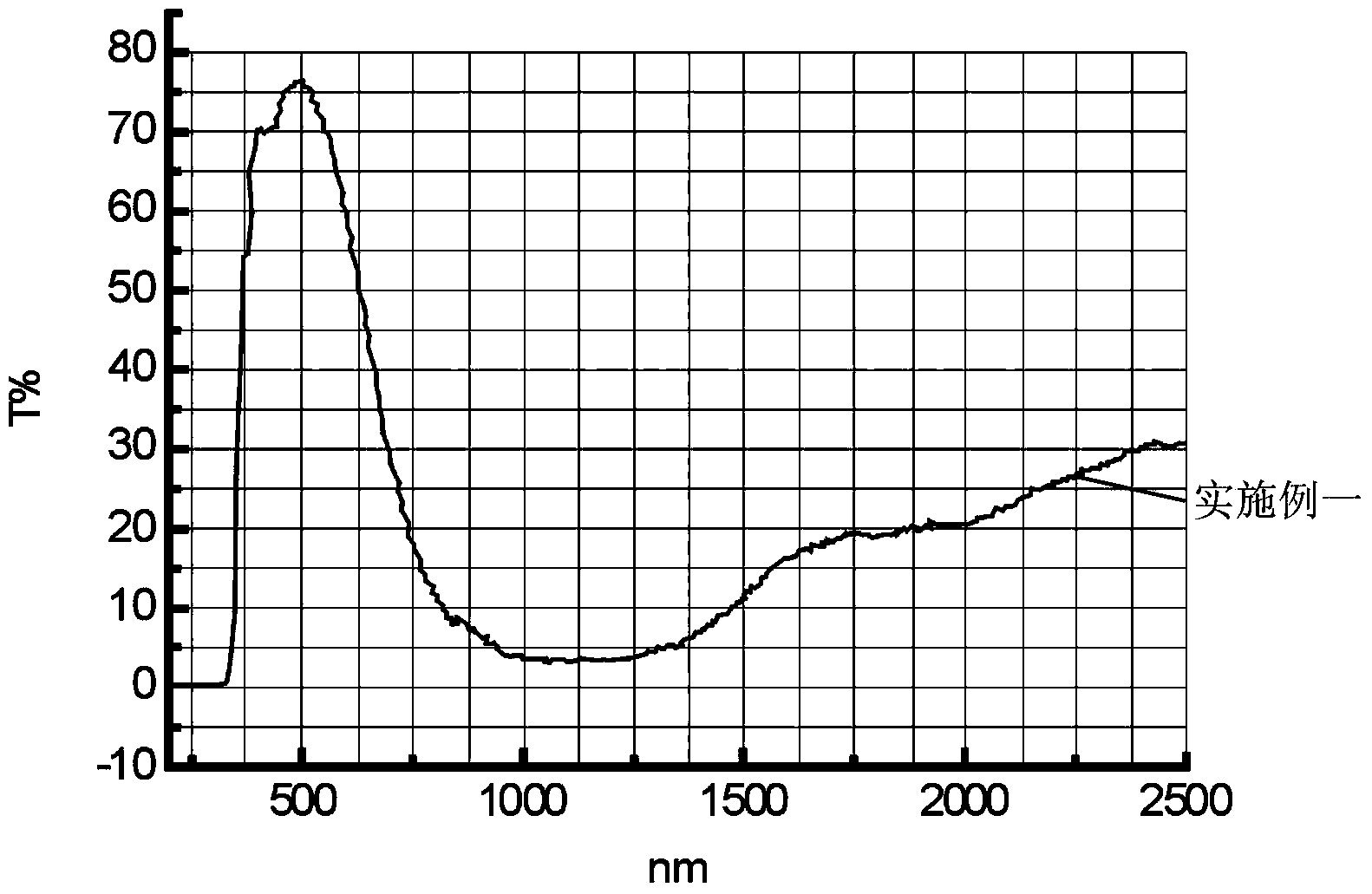

Embodiment 1

[0066] Taking the preparation of a light blue-green glass composition with a thickness of 2mm as an example, in a zirconia crucible with a temperature resistance of 2000°C, add the following raw materials: quartz sand: 500 grams, potassium feldspar: 5 grams, limestone: 30 grams, dolomite : 160g, Soda Ash: 200g, Diboron Trioxide: 4g, Fluorite: 6g, Glauber’s Salt: 6g, Carbon Powder: 1g; the coloring and coordination part of the glass body that absorbs ultraviolet rays and infrared rays can be dosed as needed.

[0067] Mix the above raw materials evenly, add 1 gram of reducing agent carbon powder to control the redox ratio, control the melting temperature to 1500-1550°C, heat for 30 minutes, heat to 1500°C, keep for another 30 minutes, then raise the temperature to 1530°C, and then , carry out clarification and homogenization, the clarification temperature is from 1450 ° C to 1300 ° C, the time is 30 minutes, finally, the molten glass liquid is poured into the molding template for...

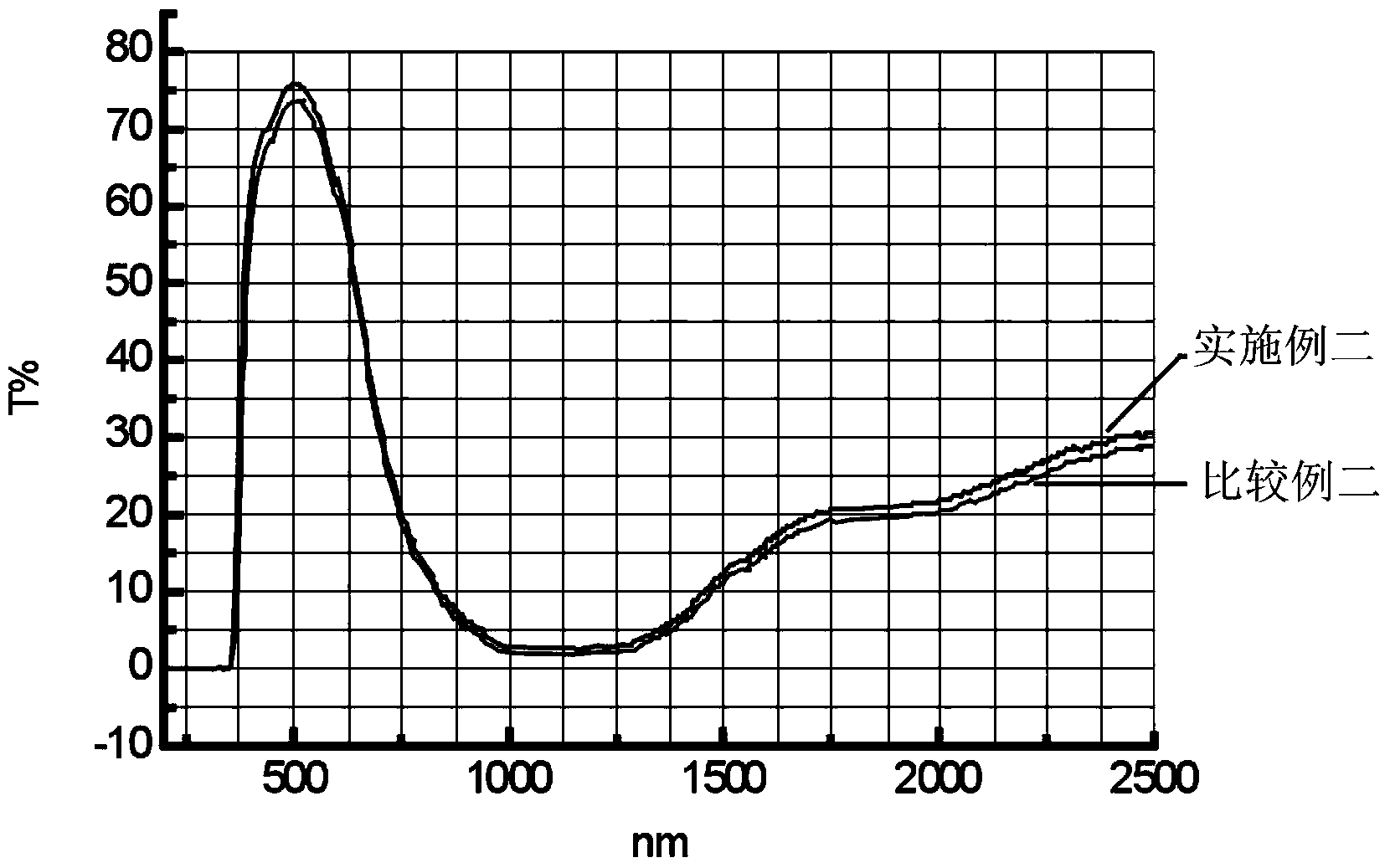

Embodiment 2

[0079] Taking the blue-green glass composition with a thickness of 4mm as an example, add the following raw materials into a zirconia crucible with a temperature resistance of 2000°C: quartz sand: 530 grams, potassium feldspar: 8 grams, limestone: 20 grams, dolomite: 155 grams Grams, soda ash: 190 grams, boron trioxide: 3 grams, fluorite: 5 grams, Glauber’s salt: 6 grams, carbon powder: 1 gram; the coloring coordination part of the glass body that absorbs ultraviolet and infrared rays: according to demand. The method for preparing the glass composition is the same as above, so it will not be repeated here.

[0080] The ingredients to obtain the glass composition are as follows:

[0081] Table 5 Glass Components in 4mm Glass Composition

[0082]

[0083] 17

[0084] Table 6 Redox parameters in 4mm glass composition

[0085]

[0086] Table 7 Spectral Properties of 4mm Glass Compositions

[0087]

[0088] In Table 5 and Table 6, co...

Embodiment 3

[0090] Taking the blue-green glass composition with a thickness of 5mm as an example, add the following raw materials to a zirconia crucible with a temperature resistance of 2000°C: quartz sand: 550 grams, potassium feldspar: 6 grams, limestone: 15 grams, dolomite: 160 grams, soda ash: 195 grams, boron trioxide: 3 grams, fluorite: 5 grams, Glauber's salt: 6 grams, carbon powder: 1 gram; the coloring coordination part of the glass body that absorbs ultraviolet rays and infrared rays: according to demand. The method for preparing the glass composition is the same as above, so it will not be repeated here.

[0091] The ingredients to obtain the glass composition are as follows:

[0092] Table 8 Glass Components in 5mm Glass Composition

[0093]

[0094] Table 9 Redox parameters in 5mm glass composition

[0095]

[0096] Table 10 Spectral Properties of 5mm Glass Compositions

[0097]

[0098] combine Figure 4 As shown, the above spectral perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com