Polyvinyl alcohol/ inorganic nanocomposite hydrogel and preparation method thereof

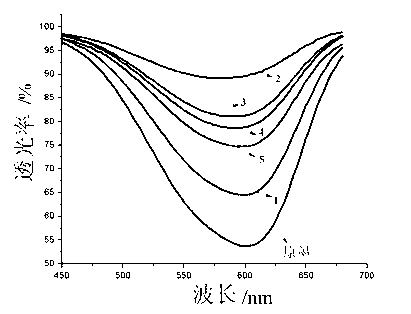

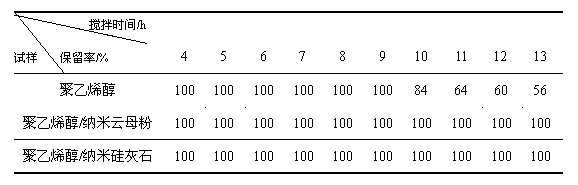

A technology of composite hydrogel and polyvinyl alcohol, which is applied in the field of polyvinyl alcohol/inorganic nanocomposite hydrogel and its preparation, can solve problems such as complicated procedures, inability to meet industrial production, and difficult operation of preparation methods, and achieve mechanical strength Good, excellent physical and chemical properties, the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A kind of polyvinyl alcohol / inorganic nanocomposite hydrogel

[0029] A polyvinyl alcohol / inorganic nanocomposite hydrogel is prepared in this way. Weigh 30g of polyvinyl alcohol and 50g of sodium alginate and dissolve them in 500 milliliters of distilled water to prepare a polyvinyl alcohol solution. Mix 3g of nano mica powder with polyethylene Mix the alcohol solution evenly, add 500g of curing agent boric acid aqueous solution (the mass percentages of boric acid and curing agent aluminum chloride are 3% and 0.1% respectively), soak and cure for 10 minutes, and obtain polyvinyl alcohol / inorganic nanocomposite hydrogel glue.

Embodiment 2

[0030] Embodiment 2 A kind of polyvinyl alcohol / inorganic nanocomposite hydrogel

[0031] A polyvinyl alcohol / inorganic nanocomposite hydrogel is prepared in this way. It takes 90 g of polyvinyl alcohol and 0.1 g of sodium alginate and dissolves it in 1000 milliliters of distilled water to prepare a polyvinyl alcohol solution with a specification of 2499. The heating temperature 90°C; mix 2.5g of nanoclay with polyvinyl alcohol solution evenly, drip into 1000g of curing agent boric acid aqueous solution (the mass percentages of boric acid and curing agent calcium nitrate are 5% and 1% respectively) through the injection needle, soak After curing for 200 minutes, the polyvinyl alcohol / inorganic nanocomposite hydrogel is obtained.

Embodiment 3

[0032] Embodiment 3 A kind of polyvinyl alcohol / inorganic nanocomposite hydrogel

[0033] A kind of polyvinyl alcohol / inorganic nanocomposite hydrogel is made in this way, taking specification is 1099 polyvinyl alcohol 60g, sodium alginate 24g heating and being dissolved in 800 milliliters of distilled waters to prepare polyvinyl alcohol solution, the temperature of heating is 95°C; mix 6g of nano-silica and polyvinyl alcohol solution evenly, squeeze out the mixed solution and drop it into 800g of curing agent boric acid aqueous solution (the mass percentage of boric acid is 4%, calcium chloride and chlorine in the curing agent aluminum chloride and calcium nitrate (1%, 6% and 3%), soaked and solidified for 600 minutes to obtain polyvinyl alcohol / inorganic nanocomposite hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com