Powder for high-entropy alloy-based composite material modified layer prepared on ferrous alloy surface

A high-entropy alloy and composite material technology is applied in the field of preparing powder for a modified layer of a high-entropy alloy-based composite material on the surface of an iron-based alloy, and can solve the problem that the thermophysical properties of the modified layer material and the base material do not match, and the modified layer Cracking, poor bonding of matrix materials, etc., to achieve excellent physical and chemical properties and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

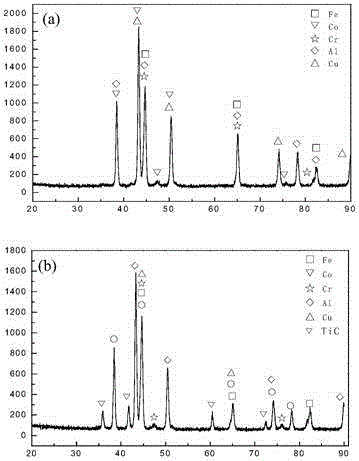

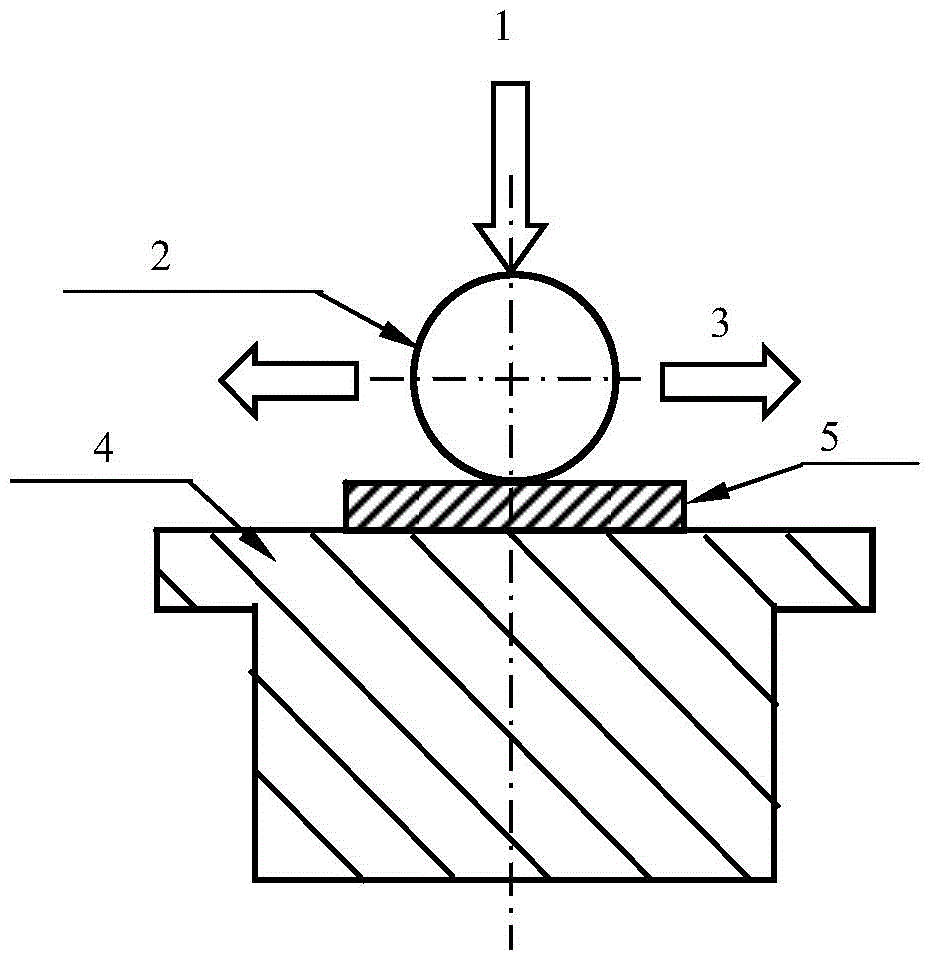

[0045] Preparation of FeCoCrAlCu high-entropy alloy modified layer on the surface of Q235 steel substrate.

[0046] FeCoCrAlCu alloy powder is prepared in equimolar ratio, the powder prepared by pure metal powder is mixed, ground and dried, and then placed on the surface of Q235 steel base material, and the thickness of the preset alloy powder is 0.5-1.5mm. The ZQM-SD 500W Nd:YAG solid-state pulsed laser is used for single-pass and multi-pass irradiation. The specific process parameters are: voltage 380V, current 110-150A, spot diameter 1.2mm, scanning speed 3-5mm / s. DLA61300 semiconductor laser was used for irradiation, the laser output power was 2kW, the laser wavelength was 980±10nm, the spot diameter was 3mm, and the scanning speed was 5-40mm / s. The overlapping rate of large-area laser beam scanning is 50%, the protective gas argon flow rate in the laser alloying process is 10-20L / min, and the thickness of the obtained laser alloyed layer is 0.7-1.5mm.

Embodiment 2

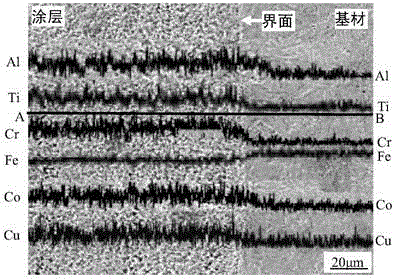

[0048] Preparation of FeCoCrAlCu+10Wt%TiC high-entropy alloy-based composite modified layer on the surface of Q235 steel substrate.

[0049] Prepare FeCoCrAlCu high-entropy alloy powder in an equimolar ratio, and add 10Wt% TiC powder of the powder. The prepared powder is mixed, ground and dried, and then placed on the surface of the Q235 steel substrate, and the thickness of the alloy powder is 0.5-1.5 mm. Use ZQM-SD 500W Nd:YAG solid-state pulsed laser for single-pass and multi-pass laser irradiation treatment. The specific process parameters are: voltage 380V, current 120-180A, spot diameter 1.2mm, scanning speed 3-5mm / s. DLA61300 semiconductor laser was used for irradiation, the laser power was 2kW, the laser wavelength was 980±10nm, the spot diameter was 3mm, and the scanning speed was 5-40mm / s. The overlapping rate of large-area laser beam scanning is 50%, the flow rate of protective gas argon in the laser alloying process is 10-20L / min, the thickness of the obtained l...

Embodiment 3

[0051] Preparation of FeCoCrAlCu+30Wt%TiC high-entropy alloy-based composite modified layer on the surface of Q235 steel substrate.

[0052] FeCoCrAlCu high-entropy alloy powder was prepared in an equimolar ratio, and 30Wt% TiC powder was added to the powder. The prepared powder is mixed, ground and dried, and then placed on the surface of the Q235 steel substrate, and the thickness of the alloy powder is 0.5-1.5 mm. Use ZQM-SD 500W Nd:YAG solid-state pulsed laser for single-pass and multi-pass laser irradiation treatment. The specific process parameters are: voltage 380V, current 120-180A, spot diameter 1.2mm, scanning speed 3-5mm / s. DLA61300 semiconductor laser was used for irradiation, the laser power was 2kW, the laser wavelength was 980±10nm, the spot diameter was 3mm, and the scanning speed was 5-40mm / s. The overlapping rate of large-area laser beam scanning is 50%, the flow rate of protective gas argon in the laser alloying process is 10-20L / min, and the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average microhardness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com