Preparation method of nylon micro powder for selective laser sintering

A laser sintering and selective technology, applied in the field of selective laser sintering materials, can solve the problems of nylon powder solubility limitation, narrow powder material sintering window, affecting the quality of SLS parts, etc., and achieve SLS sintering accuracy improvement, particle shape and flow. The effect of good performance and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 50g of nylon 12 pellets, 10g of polyvinylpyrrolidone (PVP), and 500ml of formic acid into the reaction kettle and heat up to 70°C, stir for 2 hours to fully dissolve the materials, then add 800ml of ethanol and stir to precipitate powder, filter, wash, and dry to obtain Nylon powder;

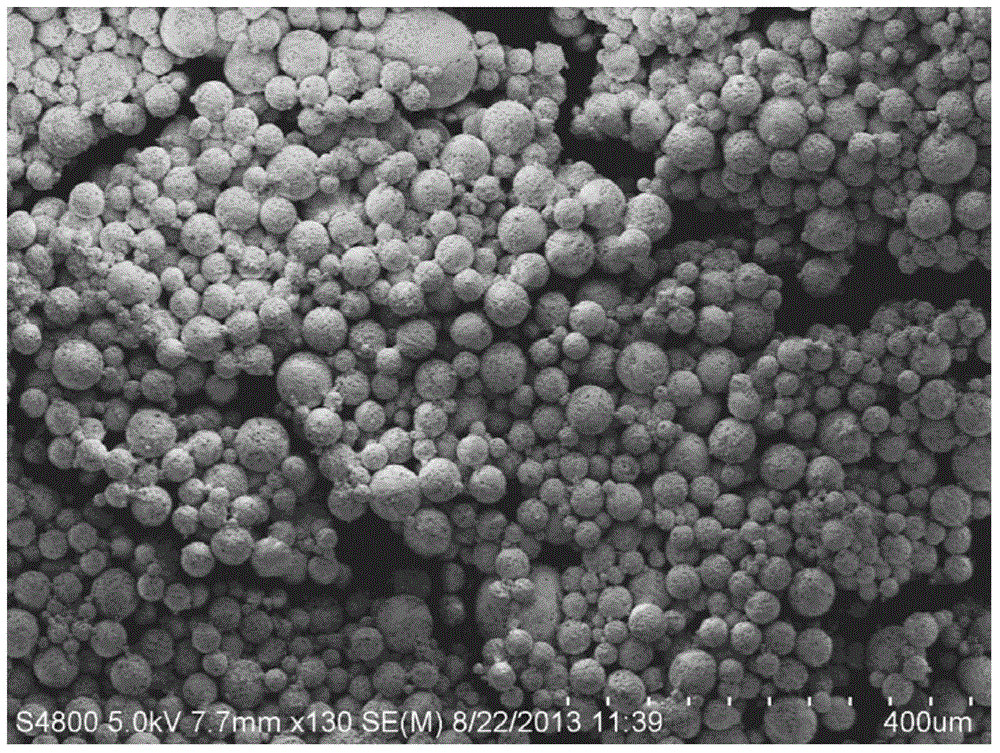

[0039] Take 50g of the above-mentioned nylon micropowder, 0.1g of flow aid nano silicon dioxide, and 0.1g of antioxidant 2,2'-methylenebis-(4-methyl-6-tert-butylphenol) in a vertical Stir and mix in an agitator for 1 hour, pass the material through a 150-mesh sieve after uniform mixing, and obtain nylon micropowder for selective laser sintering. figure 1 The scanning electron micrograph of the selective laser sintering nylon micropowder prepared for embodiment 1, Figure 6The DSC curve chart of the nylon micropowder for selective laser sintering prepared in embodiment 1. It can be seen from the figure that the powder has an average particle size of 45 microns, a melting point of 179...

Embodiment 2

[0041] Add 50g of nylon 12 pellets, 10g of polyvinylpyrrolidone (PVP), and 800ml of acetic acid into the reaction kettle and heat up to 120°C, stir for 2 hours to fully dissolve the materials, then add 600ml of ethanol and stir to precipitate powder, filter, wash, and dry to obtain Nylon powder;

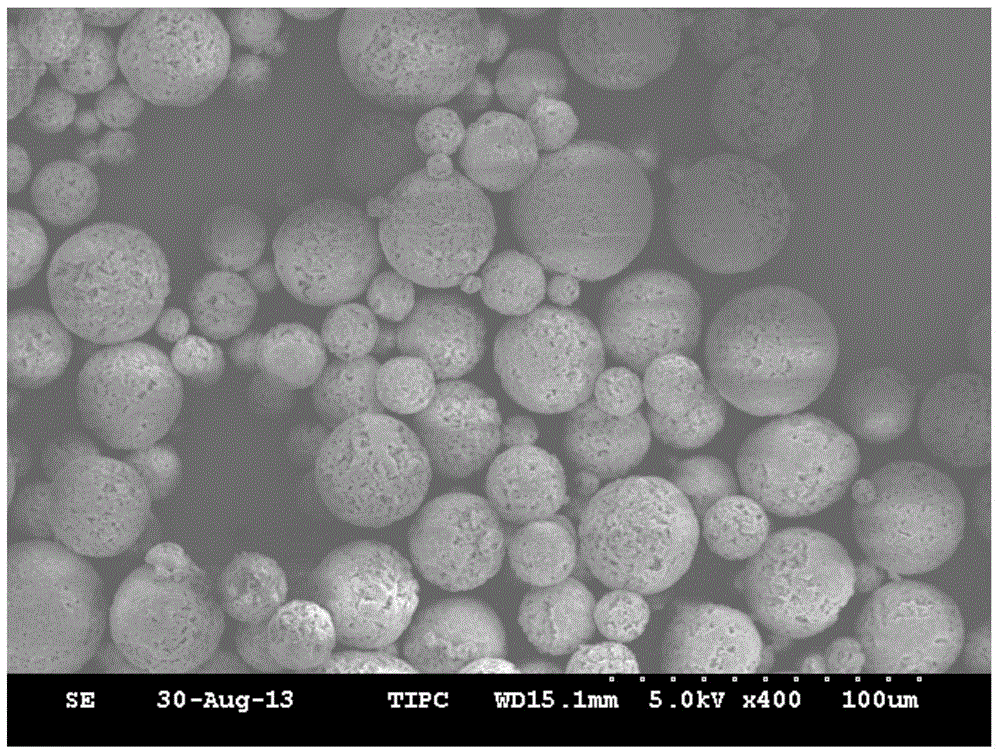

[0042] Get 50g of nylon micropowder obtained in the previous step, and 0.1g of flow aid nano-silica, 0.1g of antioxidant 2,2'-methylenebis-(4-methyl-6-tert-butylphenol), and Stir and mix in a type agitator for 1 hour, pass the material through a 150-mesh sieve after uniform mixing, and obtain nylon micropowder for selective laser sintering, with an average particle size of 50 microns. figure 2 Scanning electron micrograph of the nylon micropowder for selective laser sintering prepared in Example 2.

Embodiment 3

[0044] Add 50g of nylon 12 pellets, 10g of polyvinylpyrrolidone (PVP), and 500ml of trifluoroacetic acid into the reaction kettle and heat up to 50°C, stir for 2 hours to fully dissolve the materials, then add 800ml of ethanol and stir to precipitate powder, filter, wash, and dry , to obtain nylon powder;

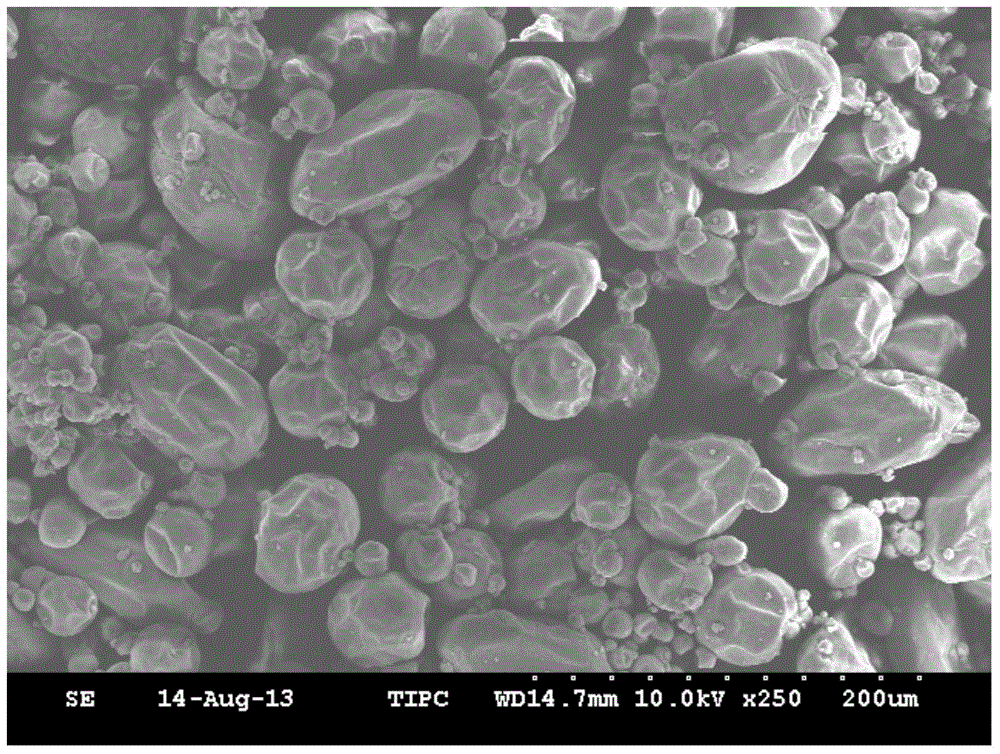

[0045] Get 50g of nylon micropowder obtained in the previous step, and 0.1g of flow aid nano-silica, 0.1g of antioxidant 2,2'-methylenebis-(4-methyl-6-tert-butylphenol), and Stir and mix in a type agitator for 1 hour, pass the material through a 150-mesh sieve after uniform mixing, and obtain nylon micropowder for selective laser sintering, with an average particle size of 90 microns. image 3 Scanning electron micrograph of the nylon micropowder for selective laser sintering prepared in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com