Magnetic isolation material and preparation method and application thereof

A magnetic material and magnetic isolation technology, applied in the fields of magnetic field/electric field shielding, electrical components, circuit devices, etc., can solve the problems of complex preparation process of magnetic isolation materials and poor performance of magnetic isolation materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

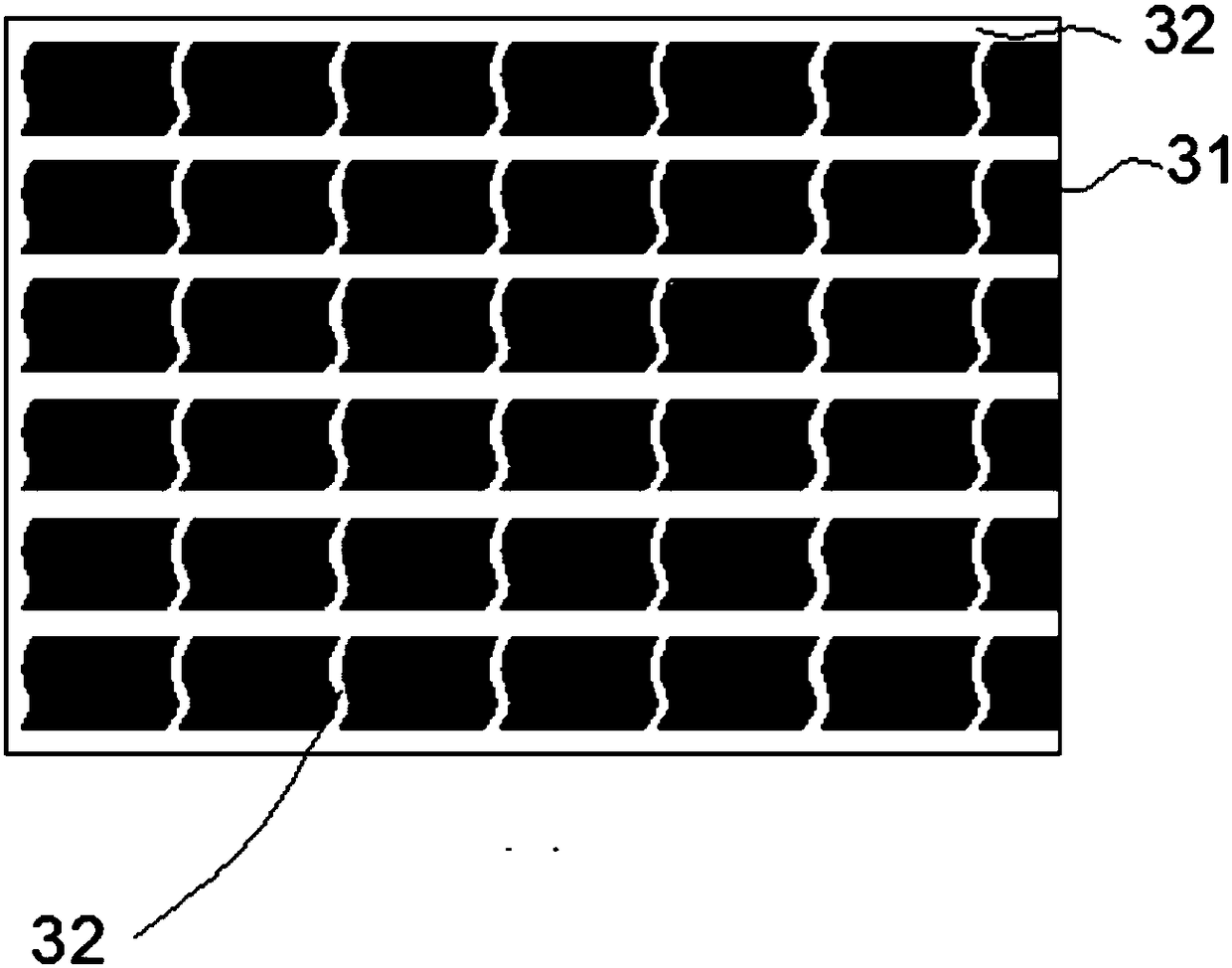

[0049] According to a preferred embodiment of the present invention, the width of the thin magnetic material layer is 10-213 mm, preferably 30-100 mm. For example, the width of the magnetic material sheet layer is 20mm, 50mm, 60mm, 142mm, 170mm, 200mm.

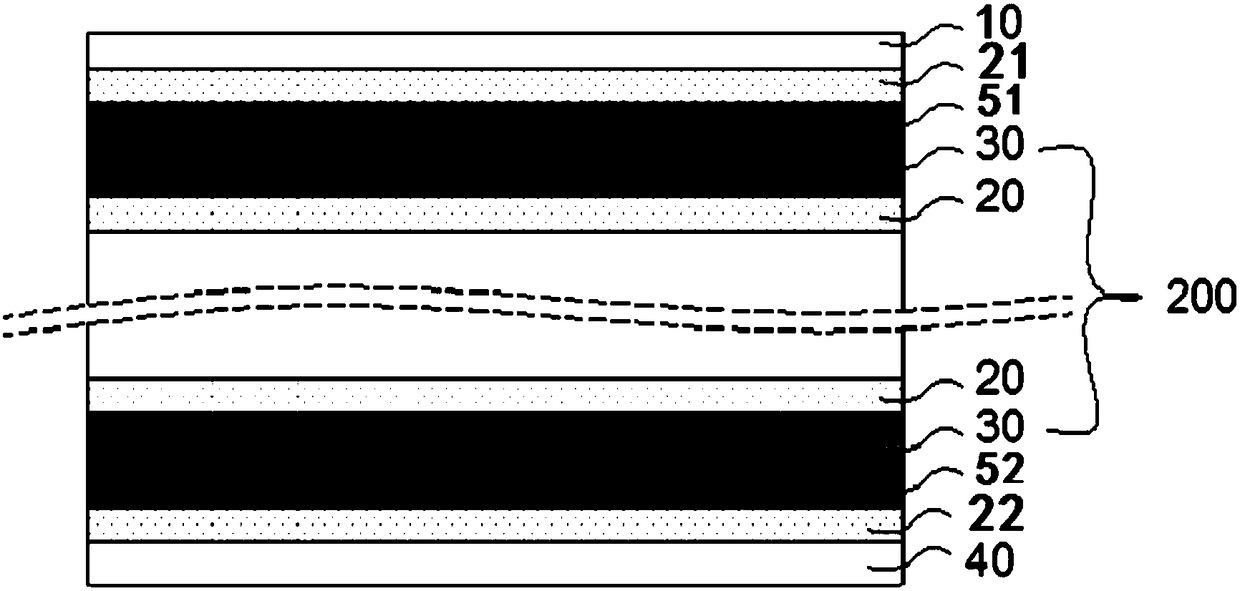

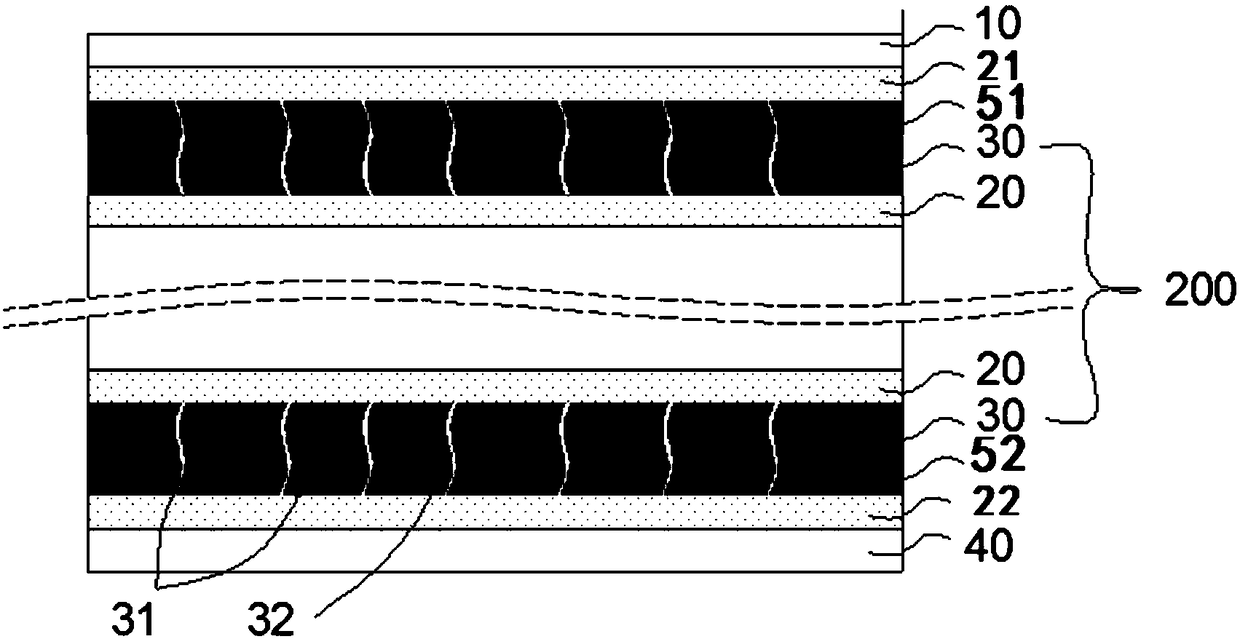

[0050] According to a preferred embodiment of the present invention, the magnetic isolation material further includes a first coating 51 located between the magnetic layer and the protective film, and / or a second coating 52 located between the magnetic layer and the release film, Wherein, the first coating and / or the second coating are each independently selected from at least one of thermally conductive or heat dissipation coatings, metal shielding coatings and ink coatings.

[0051] It should be noted that the "first" and "second" mentioned in the present invention are only for distinguishing the coating and the adhesive layer at different positions, and do not form any limitation on the specific performance parameters of th...

Embodiment 1

[0125] (1) The iron-based nanocrystalline alloy material (coil, 20 μm in thickness and 60 mm in width) was subjected to hydrogenation heat treatment at 530° C. for 120 minutes in argon gas containing hydrogen at a volume concentration of 0.5 percent;

[0126] (2) each nanocrystalline alloy material obtained in step (1) is pasted together by a 3 μm double-sided adhesive to form a magnetic layer containing a 4-layer magnetic material sheet structure;

[0127] (3) Coating one side of the magnetic layer obtained in step (2) on a coating machine with a thermal conductivity or heat dissipation coefficient of 10w / m·k nanometer heat conduction or heat dissipation coating to form a 5 μm heat conduction or heat dissipation coating (the first coating);

[0128] (4) Attach the 4 μm protective film to the thermally conductive or heat-dissipating coating obtained in step (3) through a 3 μm double-sided adhesive tape;

[0129] (5) Paste a 75 μm release film on the other side of the magnetic...

Embodiment 2

[0146] (1) The iron-based nanocrystalline alloy material (coil, 20 μm in thickness and 60 mm in width) was subjected to hydrogenation heat treatment at 600° C. for 100 min in argon gas with a hydrogen concentration of 0.4% by volume;

[0147] (2) each nanocrystalline alloy material obtained in step (1) is pasted together by a 3 μm double-sided adhesive to form a magnetic layer containing 6 layers of magnetic material sheet structure;

[0148] (3) Coating one side of the magnetic layer obtained in step (2) on a coating machine with a thermal conductivity or heat dissipation coefficient of 10w / m·k nanometer heat conduction or heat dissipation coating to form a heat conduction or heat dissipation coating of 8 μm (second coating);

[0149] (4) Bond the 75 μm release film to the thermally conductive or heat-dissipating coating obtained in step (3) through a 10 μm double-sided adhesive;

[0150] (5) Paste a 4 μm protective film on the other side of the magnetic layer with a 3 μm do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com