Composite magnetic core structure and magnetic element

A technology of magnetic components and magnetic cores, applied in the field of composite magnetics, can solve the problems of inability to achieve the best use effect of magnetic components, increase in total loss of magnetic components, increase in magnetic core loss, etc., and achieve good electromagnetic interference EMI characteristics and magnetic core loss. The effect of reducing and reducing electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

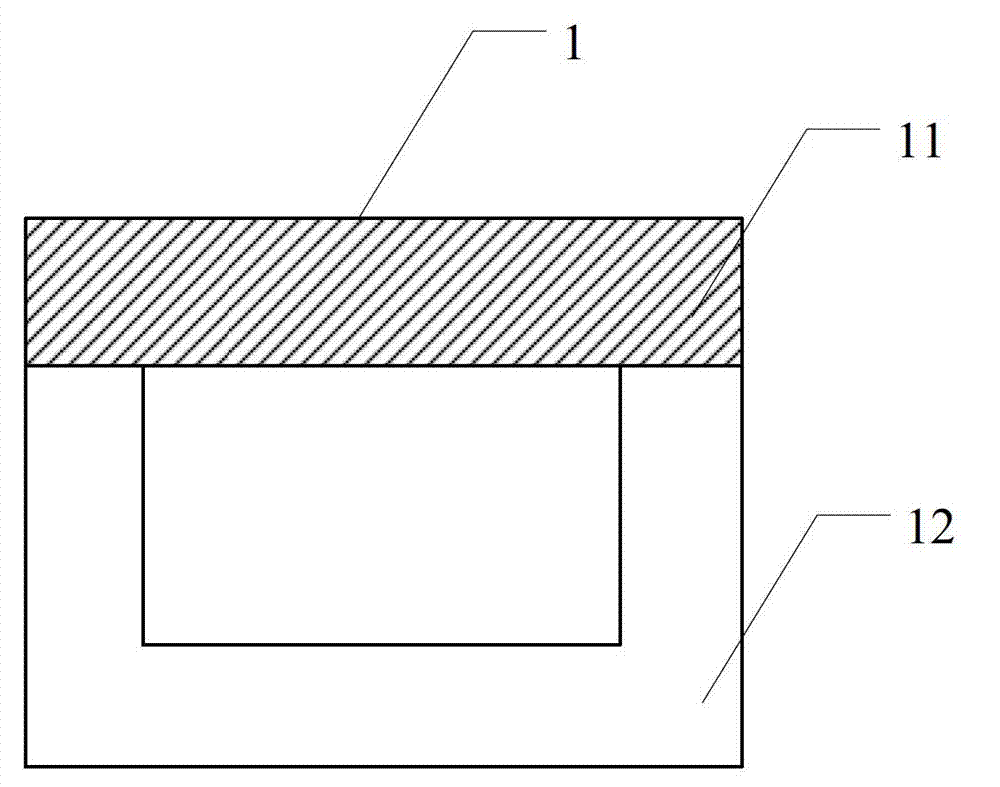

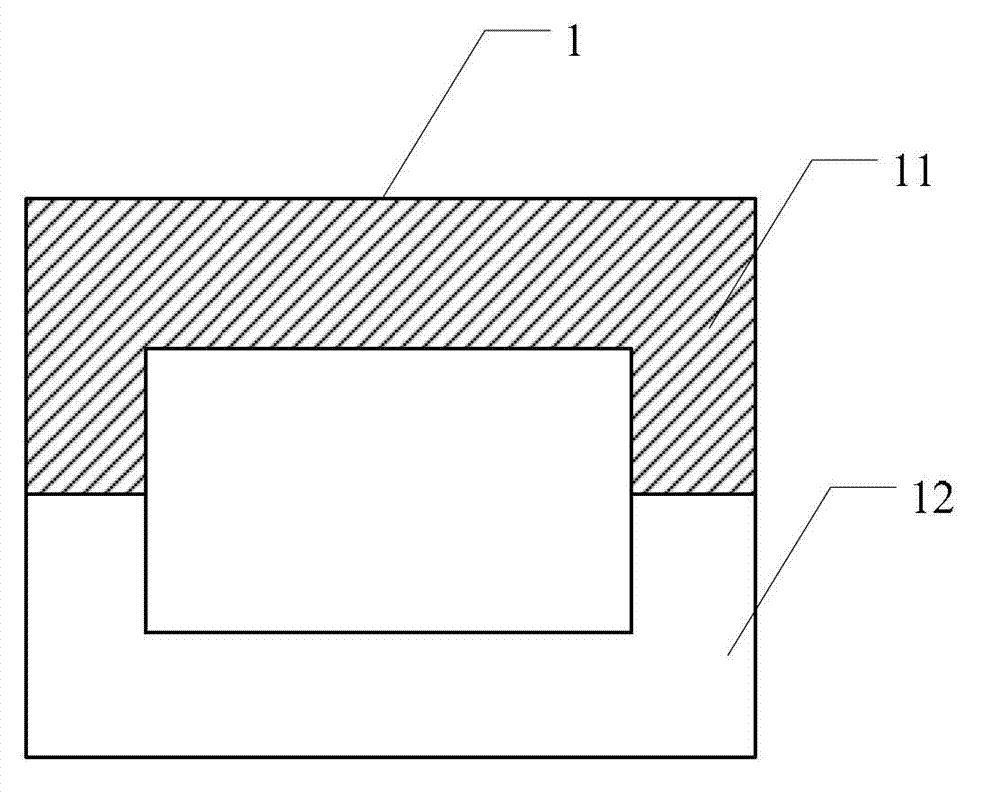

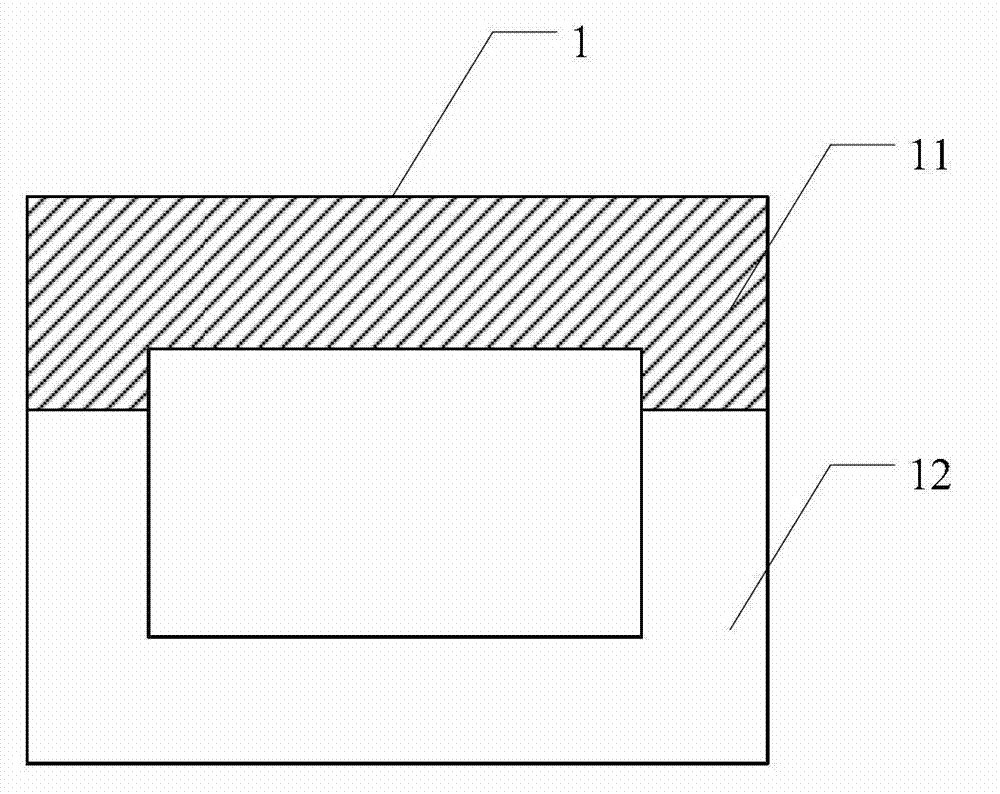

[0034] Please refer to figure 1 , figure 1 A schematic diagram of a composite magnetic core structure 1 provided by an embodiment of the present invention, wherein the composite magnetic core structure 1 includes:

[0035] The first magnetic core part 11 and the second magnetic core part 12, the first magnetic core part 11 is made of soft magnetic material with low magnetic permeability, and the second magnetic core part 12 is made of soft magnetic material with high magnetic permeability material, the first magnetic core part 11 and the second magnetic core part 12 are combined and form a magnetic flux circuit.

[0036] In the embodiment of the present invention, the soft magnetic material with low magnetic permeability is combined with the soft magnetic material with high magnetic permeability to form a magnetic flux circuit, that is, the composite magnetic core structure 1 is made of soft magnetic material with low magnetic permeability The first magnetic core part 11 and...

Embodiment 2

[0041] Preferably, this embodiment provides as figure 1 The shown composite magnetic core structure 1 is arranged in a UI shape; the shown UI-shaped composite magnetic core structure 1 includes an I-shaped set of magnetic core components and a U-shaped set of magnetic core components, wherein the I-shaped set of magnetic cores The component is a first magnetic core component 11 made of a soft magnetic material with low magnetic permeability, and the magnetic core component of the U-shaped arrangement is a second magnetic core component 12 made of a soft magnetic material with high magnetic permeability, The first magnetic core part 11 and the second magnetic core part 12 are combined to form a UI type composite magnetic circuit core;

[0042] Further, the soft magnetic material with low magnetic permeability constituting the first magnetic core part 11 can be one or more of other low magnetic permeability magnetic core materials such as nickel-zinc NiZn ferrite, alloy magnetic...

Embodiment 3

[0055] Please refer to Figure 5 , Figure 5 Another structural schematic diagram of a composite magnetic core structure 1 provided by an embodiment of the present invention, wherein the composite magnetic core structure 1 is arranged in an EI type, and the shown EI type composite magnetic core structure 1 includes:

[0056] The magnetic core part of the I-type setting and the magnetic core part of the E-type setting, wherein, the magnetic core part of the I-type setting is the first magnetic core part 11 made of a soft magnetic material with low magnetic permeability, and the E The magnetic core part of the type setting is the second magnetic core part 12 made of soft magnetic material with high magnetic permeability, and the first magnetic core part 11 and the second magnetic core part 12 are combined to form a UI type composite magnetic circuit magnetic core;

[0057] Further, the soft magnetic material with low magnetic permeability constituting the first magnetic core p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com