Magnetic material for high frequency wave, and method for production thereof

A magnetic material, high-frequency technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of high permeability, eddy current loss, high resistivity, and achieve high permeability and low eddy current loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0305] Using Nd with a purity of 99.9% and Fe with a purity of 99.9%, they were dissolved and mixed in an arc melting furnace under an argon atmosphere, and then, an ingot with a thickness of 5 mm was produced by a direct casting method. Then annealed at 1030°C for 20 hours in an argon environment, and then polished the surface after gradually cooling to prepare Nd 11.6 Fe 88.4 raw material alloys.

[0306] The raw material alloy was crushed with a jaw crusher, and then pulverized with a winch mill in an argon atmosphere, and the particle size was adjusted by vibration to obtain a powder with an average particle diameter of about 60 μm. Put the Nd-Fe raw material alloy powder into a horizontal tubular furnace, and heat it for 1 hour at 420°C in a mixed airflow with an ammonia partial pressure of 0.35atm and a hydrogen partial pressure of 0.65atm, and adjust it to Nd with an average particle size of about 30μm. 10.1 Fe 76.7 N 13.2 composition. The magnetization value of th...

Embodiment 2

[0321] The composition that embodiment 1 obtains is Nd 10.1 Fe 76.7 N 13.2 Coarse powder, in argon with an oxygen partial pressure of 1%, is subjected to a rotary ball mill, and after surface treatment is carried out in a ferric chloride solution of pH 6.2, the surface oxidation treatment is carried out while adjusting the pH to obtain a particle with an average particle size of 6 μm. Nd 8.0 Fe 60.8 N 10.6 h 7.8 o 12.8 Rare earth-iron-nitrogen (-hydrogen-oxygen) magnetic materials.

[0322] 12% by mass of epoxy resin was mixed with this material, molded into a size of 10×5×1.3 mm at a molding pressure of 1 GPa in a static magnetic field of 1.2 MA / m (uniaxial magnetic field orientation), and cured at 150° C. for 2 hours. The obtained density was 5.2 and the volume fraction of the magnetic material was 62 volume%.

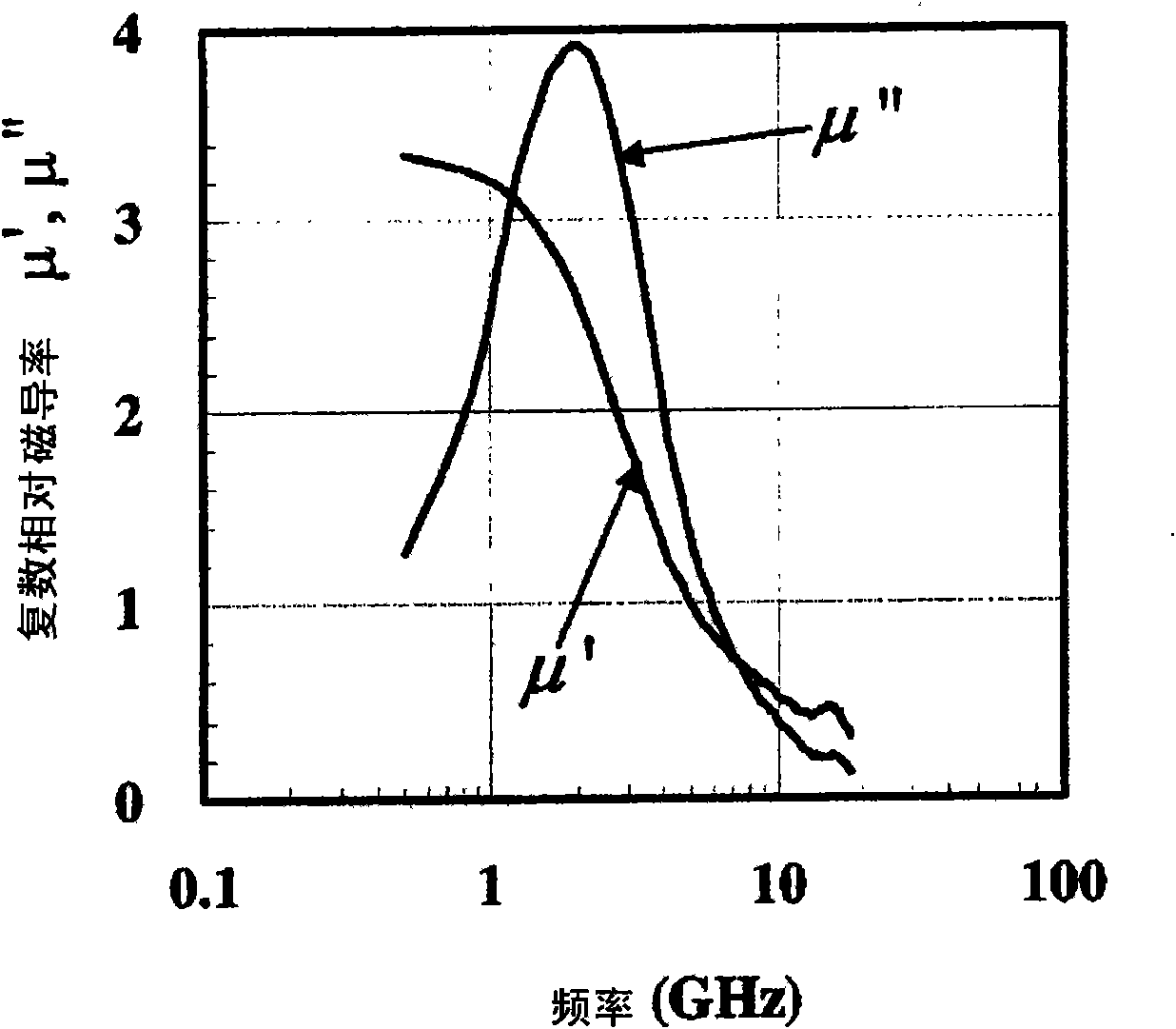

[0323] The maximum value of the imaginary number term of the complex relative magnetic permeability when the magnetic field orientation direction of the rare...

Embodiment 3 and 4

[0326] Use Nd with a purity of 99.9% and Fe with a purity of 99.9%, dissolve and mix them in a high-frequency melting furnace under an argon atmosphere, and then anneal at 950°C for 100 hours in an argon atmosphere, and then grind the surface after gradually cooling to prepare a composition of Nd 10.5 Fe 89.5 raw material alloys.

[0327] The raw material alloy was pulverized with a jaw crusher, and then pulverized with a pin mill in an argon atmosphere, and then the particle size was adjusted with a sonic classifier to obtain a powder with an average particle diameter of 50 μm.

[0328] Put the Nd-Fe raw material alloy powder into a horizontal tubular furnace, heat treatment at 420°C in a mixed flow of ammonia partial pressure of 0.35atm and hydrogen partial pressure of 0.65atm for 2 hours, then, at 400°C, under argon gas Medium annealing for 30 minutes, adjusted to Nd with an average particle size of 25 μm 9.1 Fe 77.3 N 13.6 composition.

[0329] The magnetization valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com